Different siting scenarios for PV power plants require consideration of different power plant layout design options. In PV power system design, the way the module array supports are operated has a great impact on the total solar radiation received by the power generation system, thus affecting the power generation capacity of the PV power system.

A safe and economical PV support system is the focus of attention. As an important component of a PV power plant, PV supports carry the main body of the PV power plant for power generation. The choice of bracket directly affects the operational safety, breakage rate and construction investment of PV modules. Choosing the right PV bracket will not only reduce the project cost, but also reduce the post maintenance cost.

Photovoltaic bracket can be classified in the form of connection mode, installation structure and installation location. According to the connection form, it is divided into welding type and assembly type; according to the installation structure, it is divided into fixed type and day by day type; according to the installation location, it is divided into ground type and roof type, etc. At present, there are 3 types of brackets used in most PV power plants: fixed conventional bracket, adjustable tracking bracket and flexible PV bracket.

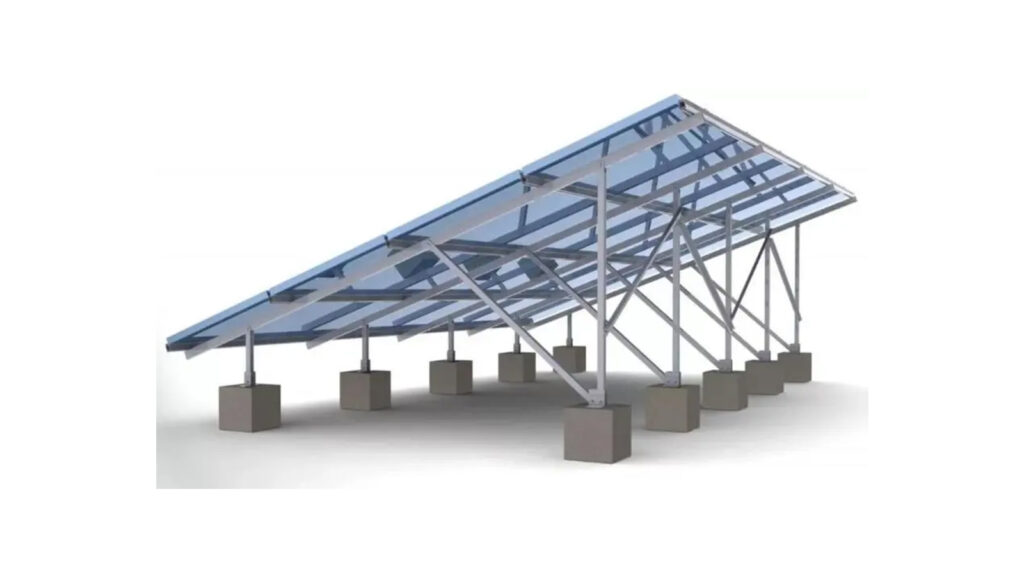

Fixed photovoltaic bracket

This refers to the mounting system where the orientation, angle, etc. remain unchanged after installation. The fixed mounting method directly places the solar photovoltaic modules toward the low latitude area, at a certain angle to the ground, to form a solar photovoltaic array in series and parallel, so as to achieve the purpose of solar photovoltaic power generation. There are various fixing methods, such as ground fixing methods are pile method (direct burial method), concrete block counterweight method, pre-buried method, ground anchor method, etc. Roofing fixing methods have different programs with different roofing materials.

Adjustable tracking bracket

Tracking system is to try to align the sun so that the sun rays receive more sun rays per unit area of the battery panel, thus increasing the power generation. Currently, tracking systems include single-axis tracking systems and dual-axis tracking systems, and single-axis tracking systems are divided into horizontal single-axis tracking systems and oblique single-axis tracking systems.

(1) Horizontal single-axis tracking

Flat single-axis tracking bracket refers to the bracket form that can track the rotation of the sun around a horizontal axis, usually with the axial direction of north-south. The common tracking angle range is ±60°, and there are also products with a tracking angle range of ±45°. Flat single-axis system usually occupies 1.1~1.3 times of the fixed one, and the power generation capacity is improved in 8%~15%, and the price is improved in 5%~10%.

(2) Oblique single-axis tracking

In inclined single-axis tracking mounts, PV modules rotate around an inclined axis to track the sun to obtain higher power generation. The footprint of inclined single-axis system is usually 2~4 times of fixed type, and the power generation is improved in 15%~20%, and the price is improved in 10%~15%.

(3) Dual-axis tracking

Dual-axis tracking brackets can rotate in both east-west and north-south directions to track the azimuth and altitude angle of solar incidence throughout the day. The area occupied by dual-axis tracking system is usually 2~4 times of fixed type, and the power generation capacity is improved by 25%~30%, and the price is improved by more than 60%. However, the dual-axis tracking system is more complex and therefore has more mechanical structures and general operational stability.

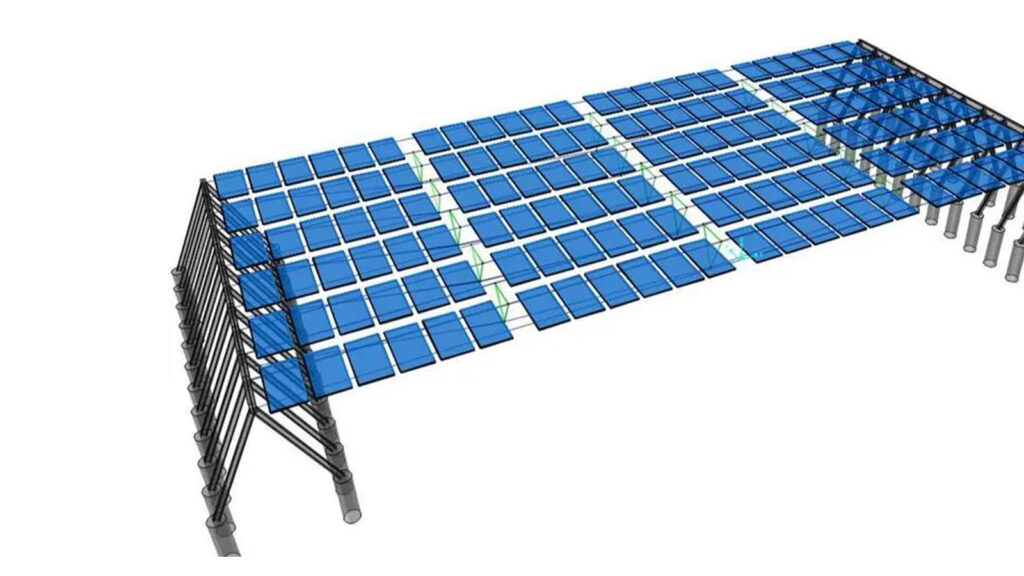

Flexible Racking

PV flexible racking is a kind of large-span PV module support structure fixed at both ends and formed by pre-stressed flexible cable structure. The span of the cable structure is usually between 20 and 40 meters, up to 100 meters. At the same time, the modules can be 2 meters to 30 meters above the ground, which has the advantages of high headroom under the modules and low number of piles for arrangement. The installation angle of PV modules in flexible mounts is generally small, usually 10°-15°.

Flexible bracket is mainly applicable to scenarios such as mountainous projects with large slope (e.g. above 35°), fishery-photovoltaic and agricultural-photovoltaic projects with high headroom requirements. There are also great prospects for the application of distributed PV with high space requirements such as sewage treatment plants and parking lots.

The above three common types of brackets need to be considered in terms of layout design, power generation estimation, cost and other factors, for example, fixed adjustable brackets and tracking brackets are more suitable for areas with strong direct radiation.

Maysun Solar, as a PV module manufacturer with 15 years of professional experience, can provide you with high quality solar panels, click the button below to contact us and get a product quote.

You may also like:

How to Effectively Clean and Intelligently Maintain Photovoltaic Systems for Optimal Performance?

Explore how scientific cleaning and intelligent maintenance can ensure the efficient operation of commercial and industrial photovoltaic systems. Practical advice covers module cleaning frequency, monitoring system configuration, and long-term strategies for energy savings and performance enhancement.

2025 European Photovoltaic Policy Map: Deployment Paths and Regional Strategies for Commercial and Industrial Photovoltaics

A comprehensive analysis of the 2025 European commercial and industrial photovoltaic policy map, focusing on deployment strategies, incentive comparisons, and zero-investment models to support businesses in achieving an efficient and green transition.

Empowering Factories with Solar Energy A Strategic Tool for Controlling Production Electricity Costs

Commercial and industrial solar is becoming a key solution for factories to reduce electricity costs and hedge against price fluctuations. This article systematically analyzes its deployment models, cost advantages, and sustainable value pathways.

How Businesses Can Offset Carbon Taxes with Solar Power

This article analyzes the latest carbon tax policies and photovoltaic deduction strategies, helping European businesses legally reduce taxes, increase profits through solar investment, and achieve a win-win situation for both economy and environment.

Forecast and Response: Seizing the Next Decade’s Growth Dividend in Europe’s Commercial and Industrial Photovoltaics Market

Maysun Solar analyzes the growth trends of commercial and industrial photovoltaics in Europe over the next ten years, from policies and ESG to technological innovation, helping companies seize the initiative in the energy transition.

How to Calculate Solar System ROI and Optimize Long-Term Returns?

Solar power is becoming a key solution for businesses to reduce costs and improve efficiency. Accurately calculating ROI and optimizing long-term returns are essential to maximizing investment value.