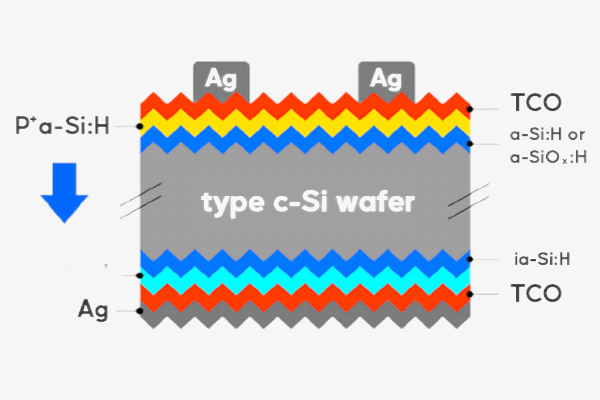

A: The journey of HJT (Heterojunction Technology) began in 1974 when Waler Fuhs first introduced the concept, blending the strengths of amorphous silicon with crystalline silicon materials. This innovation marked the nascent phase of HJT cell development. In 1989, a significant breakthrough occurred when the Sanyo Group successfully developed HJT solar cells and secured a patent, achieving an initial efficiency of 15%. By 1997, Sanyo had not only trademarked HJT but also commenced the commercial distribution of photovoltaic modules, heralding the advent of HJT technology. The expiration of Panasonic’s patent protection for HJT cells post-2010 opened the doors for various manufacturers to enhance this technology. Consequently, HJT solar panels transitioned to industrial production, with efficiencies progressively increasing. Entering the commercial phase in 2017, the HJT sector saw an influx of companies initiating small-scale production. With growing production capacities exceeding 100 MW, the future of HJT cells shines brightly, promising further advancements.