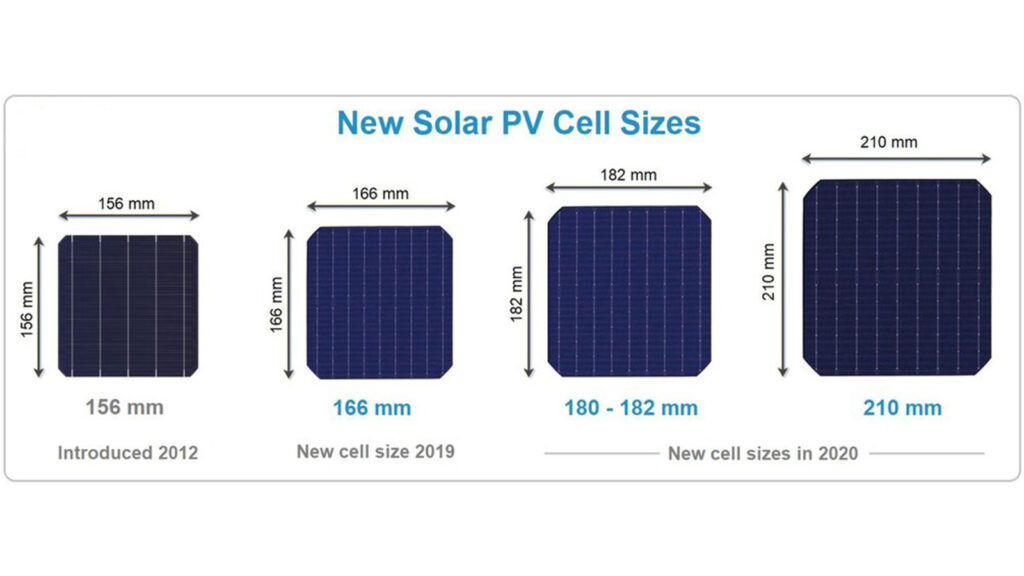

Counting the iterative trajectory of PV wafer size, from 125mm to 166mm, from 182mm to 210mm, even though the size is getting bigger and bigger, but the shape has always been square, which has almost become a thinking stereotype in the PV industry. Now, with the wafer size temporarily reached a consensus in 182mm and 210mm, the wafer link cost reduction and efficiency began to find a breakthrough again, focusing on “rectangular” become an important path.

Size Diversification

The wide range of innovative rectangular sizes has taken the industry by surprise. When Trina Solar launched its new silicon wafer product “210R” in April 2022, the rectangular silicon wafer was made public for the first time, and the decades-old thinking in the PV industry that silicon wafers should be square was completely dismantled. Since then, including the “182R” and other rectangular cell module products continue to launch, more rectangular silicon cells become the industry’s focus.

In terms of 182R, the current size of 182R is 183.75*182mm, 185*182mm, 186*182mm and so on. For the sake of efficiency and power improvement, the cell size specifications are wildly increasing all the way. For example, Longi’s rectangular wafers use the 183.75*182mm specification, JinkoSolar uses 186.8*182mm, and JA uses 185*182mm.

Considerable value

The reason for the rapid popularity of rectangular silicon wafers in the short term is simple: firstly, technology has improved, followed by the system value brought by the increase in module power, and significant supply chain value.

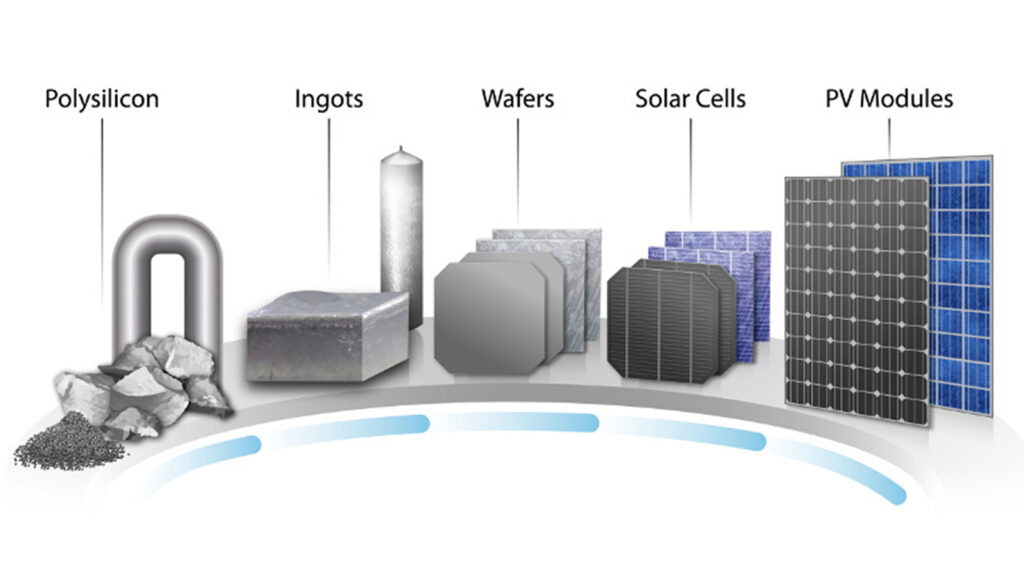

It is well known that monocrystalline silicon wafers are processed from monocrystalline silicon rods, and as the technology for producing silicon rods has improved, its edge material has gradually become available for wafer production, in addition to the center of the rod. The production of rectangular silicon wafers also helps to make full use of the silicon material and can reduce costs. On the other hand, the development purpose of the photovoltaic industry has always been to pursue the reduction of the cost of kilowatt-hour electricity. At present, the conversion efficiency of each PV module manufacturer’s products is not very different, in order to pursue cost reduction and efficiency, highlight product differentiation, increase the power becomes the optimal choice.

In this context, the use of rectangular silicon wafers by module manufacturers can significantly increase the power of their products and help create higher customer value. Last year, Trina Solar released its 210R-based modules with a 30W increase in power; shipping costs are also significantly lower, with a 5.3% increase in boxed wattage and a 1.86% savings in overall kWh costs. The customer value can be seen.

So it seems that the 210R-based module size provides a possible outlet for the current confusing rectangular silicon wafers to maximize value upstream and downstream of the industry chain. At the same time, the convergence of the two will also produce considerable benefits for industry unification, synergy and ecological construction.

Industry Chain Turmoil

The unification of rectangular wafer size and module size is becoming a unanimous call from the industry chain. However, the diversity of rectangular wafer sizes has also thrown the industry chain into confusion.

For upstream wafer manufacturers, the most direct cost is a significant increase in non-technical costs. Their supply chain and inventory management, capacity planning, and equipment automation rates are all affected by the variation in rectangular wafer sizes, which in turn reduces production efficiency and inhibits the formation of a scale-up effect for rectangular technology. This cost also covers the auxiliary material link enterprises, such as backsheet, glass, aluminum profiles, etc.

For the downstream terminal, with the rectangular wafer size changes, module size will also vary widely, causing a great impact on the installation. In this regard, a senior professional said, “The rectangular wafer size is not uniform, which brings a huge burden to the industry chain and defeats the original purpose of successive innovations in the PV industry, namely to optimize the industry chain support, build ecology, reduce the cost of electricity, and promote the maximum value of the application end.”

Maysun Solar, as a PV module manufacturer with 15 years of professional experience, has also launched module products with 182*210mm rectangular wafers. Interested parties can click the button below for product details or contact us via WhatsApp.