Maysun Solar HJT Solar Panel Full Black 410W-430W Bifacial Glass Glass

Power Output: 410W 415W 420W 425W 430W

Efficiency: 21.2-22.3%

Dimensions (L × W × H): 1760 mm × 1098 mm × 30 mm

Weight: 22 kg

Packaging: 36 pcs/pallet, 936 pcs/40’HQ

Warranty: 30-year product and performance guarantee

HJT : The Pinnacle of Solar Cell Innovation

Peak Performance

210mm x 105mm HJT Half-Cell Innovation

Utilizing cutting-edge 210mm x 105mm HJT half-cell innovation, these solar cells excel in operational efficiency. Equipped with identical designs on both sides, they attain an exceptional bifaciality of 95%. The outstanding temperature coefficient characteristic of HJT technology further amplifies sunlight absorption and its transformation into electrical power, maximizing energy yield.

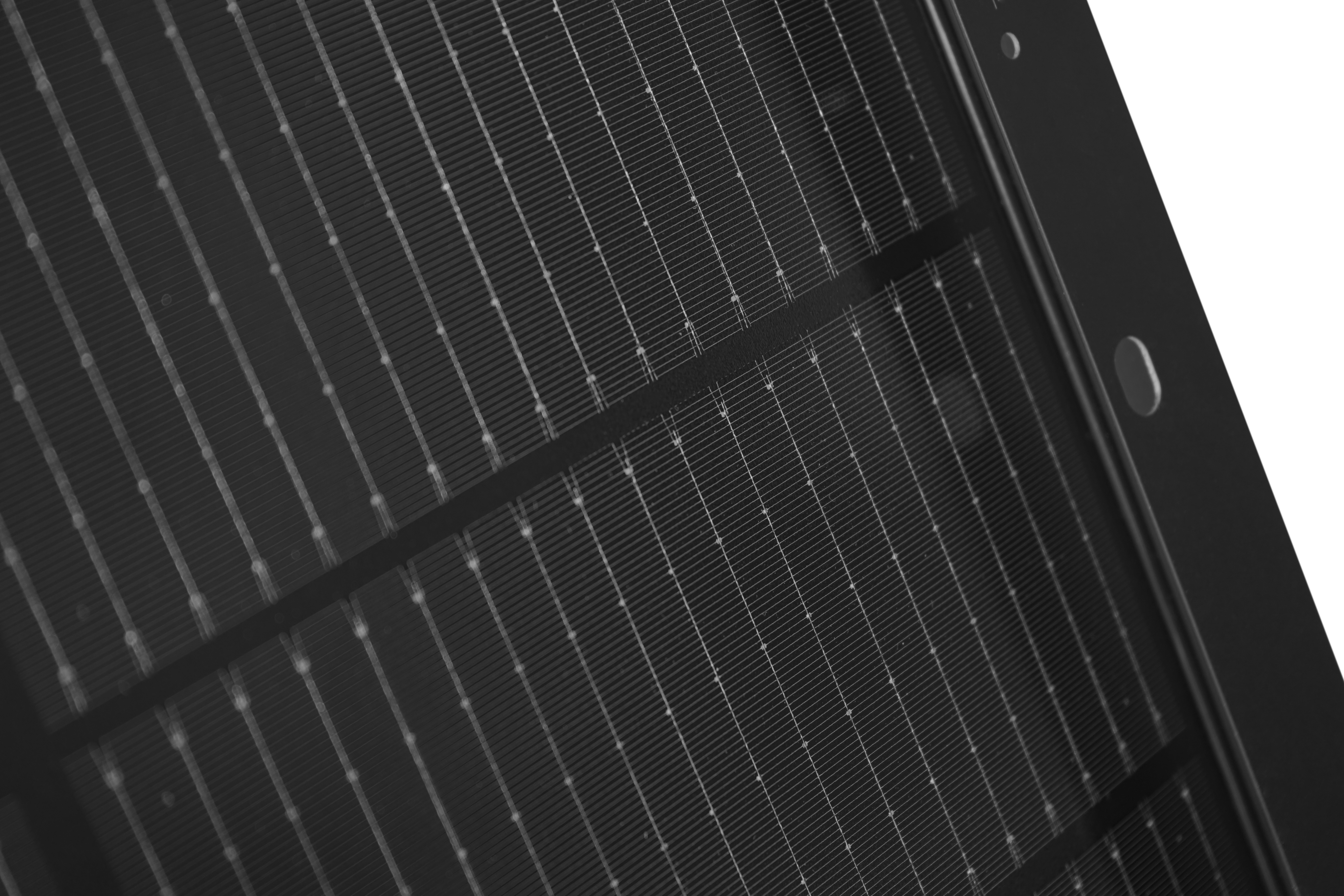

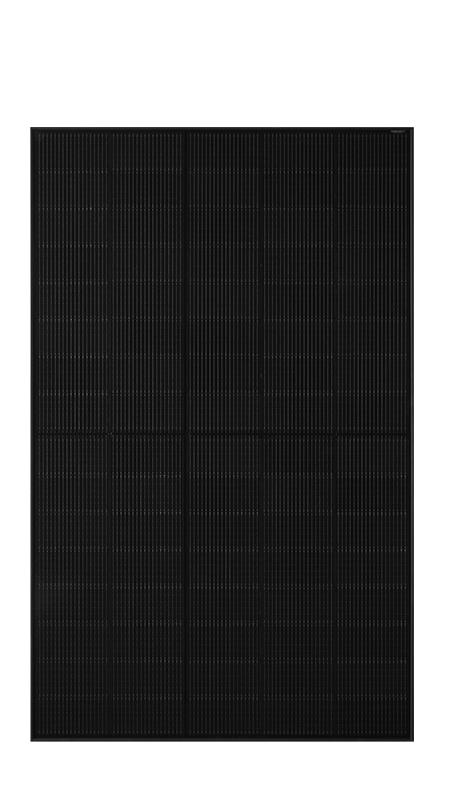

Full Black Design

The HJT 410W-430W solar panels present a sophisticated full black design, characterized by their sleek and uniform appearance. This uniformity in color contributes to a visually appealing and cohesive aesthetic. Perfectly suited for residential rooftop installations, these panels blend seamlessly with various architectural styles, enriching the home’s appearance with a contemporary and elegant touch.

Additional Product Advantages

HJT – High-Quality Solar Modules

Damage-free welding process

The solar cell soldering process employs temperatures below 250°C, minimizing the potential for heat-induced damage. This careful approach preserves the integrity of the solar cells, ensuring their optimal performance and longevity.

Optimal temperature coefficient

HJT cells are distinguished by their superior temperature coefficient of -0.24%/°C, maintaining higher power output even under elevated temperatures. This characteristic not only boosts electricity production but also contributes to a lower levelized cost of electricity (LCOE), enhancing overall system efficiency.

SMBB technology

Utilizing SMBB 18BB technology, HJT cells experience uniform stress distribution, which significantly diminishes the risk of micro-cracks by shortening the current transmission distance and minimizing power loss. This innovation bolsters the durability of HJT solar panels and notably augments their photovoltaic conversion efficiency.

No LID and LeTID Effect

Incorporating an anti-reflection layer with conductive ITO, HJT cells successfully counteract both LID and LeTID effects. Over a span of 30 years, these cells demonstrate minimal degradation below 11.1%, ensuring consistent and enhanced power generation over their entire service life.

PID Resistance

HJT cells feature a TCO (Transparent Conductive Oxide) coating without an additional insulating layer. This structural choice endows TCO with the ability to prevent potential-induced degradation (PID), securing the cells' efficiency and longevity.

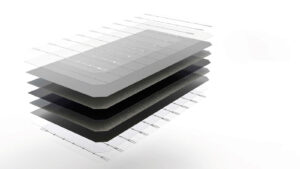

30-Year Product Warranty

HJT solar panels utilize double-glass design, which provides excellent weather resistance, corrosion resistance, and durability. Additionally, the POE encapsulant film incorporated in these solar panels offers outstanding moisture barrier capabilities, anti-PID performance, and aging resistance. These features collectively contribute to a 30-year product and performance warranty for the HJT solar panels.

Non-cut Cell Technology

The manufacturing of HJT solar modules involves a novel half-cell processing technique that eschews the micro-cracks associated with cutting cells into halves, a frequent issue in conventional half-cell production. This approach significantly elevates the modules' performance reliability.

Enhanced Adaptability

With the incorporation of HJT technology, thin-film cells exhibit exceptional flexibility and an increased capacity to bend, significantly reducing the risk of hidden micro-cracks during transport and installation. This ensures the modules' structural integrity and reliability.

Superior Low-Light Efficiency

HJT cells integrate i-a-SiH thin films with crystalline and doped amorphous silicon, creating a defect-free crystalline silicon surface. This results in an exceptionally high open-circuit voltage (750 mV), facilitating efficient power generation even in low-light conditions such as early mornings.

| Module Type | 410 | 415 | 420 | 425 | 430 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Test Condition | STC | NOCT | STC | NOCT | STC | NOCT | STC | NOCT | STC | NOCT |

| Peak Power Watts-PMAX (Wp) | 410 | 317 | 415 | 321 | 420 | 325 | 425 | 329 | 430 | 333 |

| Maximum Power Voltage-VMPP (V) | 25.02 | 23.67 | 25.08 | 23.87 | 25.14 | 24.09 | 25.2 | 24.28 | 25.26 | 24.5 |

| Maximum Power Current-IMPP (A) | 16.38 | 13.39 | 16.54 | 13.45 | 16.71 | 13.49 | 16.86 | 13.55 | 17.02 | 13.59 |

| Open Circuit Voltage-VOC (V) | 29.72 | 28.54 | 29.79 | 28.81 | 29.86 | 29.05 | 29.93 | 29.31 | 30.00 | 29.56 |

| Short Circuit Current-ISC (A) | 17.29 | 14.05 | 17.46 | 14.10 | 17.63 | 14.15 | 17.75 | 14.20 | 17.92 | 14.25 |

| Module Efficiency ηm (%) | 21.2 | 21.5 | 21.7 | 22.0 | 22.3 | |||||

Frequently Asked Questions

A: The journey of HJT technology began in 1974 when Waler Fuhs first introduced the concept of merging amorphous and crystalline silicon materials to create the HJT structure. Initial development was gradual, with Sanyo Group pioneering the first successful HJT solar cells in 1989 and securing a patent. These early HJT panels achieved a 15% efficiency rate. Sanyo’s 1997 trademark registration for HJT marked a commercial milestone, with Panasonic’s patent expiry in 2010 further accelerating development. This opened doors for various manufacturers to enhance HJT technology, leading to industrial-scale production and continuous efficiency improvements. By 2017, HJT technology had entered a commercial phase, with increasing adoption and production capacities exceeding 100 MW, highlighting a bright future for HJT cells.

A: HJT cells employ a heterojunction structure, where amorphous silicon is layered onto an N-type silicon wafer, acting as a passivation layer to elevate open-circuit voltage and efficiency. An additional transparent conductive TCO layer enhances the cell’s performance. The manufacturing process benefits from low-temperature procedures, around 200 degrees for silver paste, facilitating the use of thinner N-type wafers and pointing towards potential cost reductions.

A: HJT cells are distinguished by their superior power generation capacity and efficiency potential. The technology’s streamlined manufacturing process, involving fewer steps than PERC and TOPcon technologies, significantly simplifies production and paves the way for cost savings. HJT’s symmetrical design promotes bifacial power generation, blending the best of crystalline silicon and thin-film technologies for a leap forward in solar innovation. Additionally, incorporating perovskite layers into HJT cells can further enhance their conversion efficiency, underscoring the technology’s leading edge in solar cell advancement.

Further Reading About HJT Solar Panel

Learn More Information About HJT Techonology

2024 Guide of SMBB Solar Cells: Why Choose SMBB Solar Panels?

Table of Contents Intro In the dynamic landscape of solar energy, technological innovations continuously reshape the industry. One such transformative advancement is the evolution of solar cell busbar technology, notably transitioning from Multi BusBar (MBB) to the more sophisticated Super Multi Busbar (SMBB) design. The intricate interplay between these advancements

Bifacial solar panels: Benefits & Installation Scenarios (2024)

Table of Contents What is a bifacial solar panel? A bifacial solar panel is a type of solar module that is designed to capture sunlight on both the front and rear sides. Unlike traditional monofacial solar panels that only have a single-sided photovoltaic surface, bifacial panels have photovoltaic cells on

What Are Heterojunction Technology (HJT) Solar Panels: Advantages & Applications

Table of Contents What are HJT Solar Panels? Heterojunction(HJT) solar panel, also known as Silicon heterojunctions (SHJ) or Heterojunction with Intrinsic Thin Layer (HIT) solar panel, is a collection of HJT solar cells that leverage advanced photovoltaic technology. HJT cells combine the benefits of crystalline silicon with thin-film technologies. These