Table of Contents

Intro

In the dynamic landscape of solar energy, technological innovations continuously reshape the industry. One such transformative advancement is the evolution of solar cell busbar technology, notably transitioning from Multi BusBar (MBB) to the more sophisticated Super Multi Busbar (SMBB) design. The intricate interplay between these advancements and their consequential impact on solar panel efficiency, performance, and application scenarios establishes a compelling narrative for the future of solar energy solutions. This blog delves into the connection between MBB and SMBB, elucidates the performance advantages of SMBB solar cells, and explores the wide range of application scenarios of HJT solar panels as a representative of the advanced technology applied to SMBB.

What is SMBB Technology?

What Is Busbar?

On most solar panels available today, you can easily identify one or more busbars (BB) – those prominent ‘silver-looking lines’ that stand out. These thin, rectangular strips are printed on both the front and rear sides of the solar cell within the panel and serve as conduits for the electricity produced by the solar cell itself. Often made of silver-plated copper, these busbars act like “highways” within the solar panel, gathering and connecting the electricity generated by the panel’s solar cells. They form the direct current (DC) power, which is then channeled away and conditioned into Alternating Current (AC) power by the inverter. This AC electricity is subsequently ready for immediate use, storage, or export to the grid.

Evolution of MBB and SMBB technology

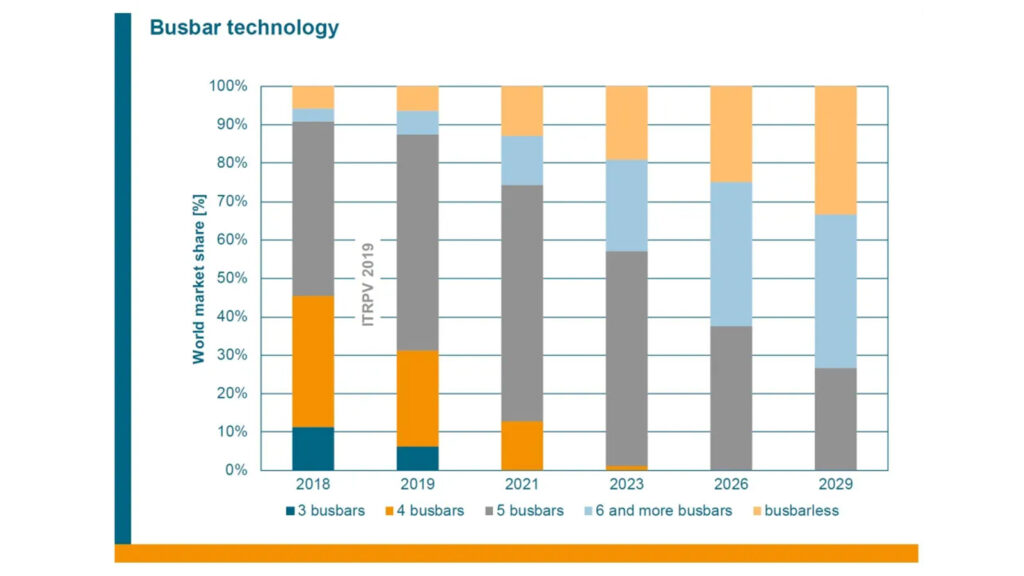

Initially (2002), solar cell sizes were 125 mm and 2BB (2 busbars). This gradually evolved to 156 mm (3BB), 158 mm (4BB) and 158.75 mm (5BB).

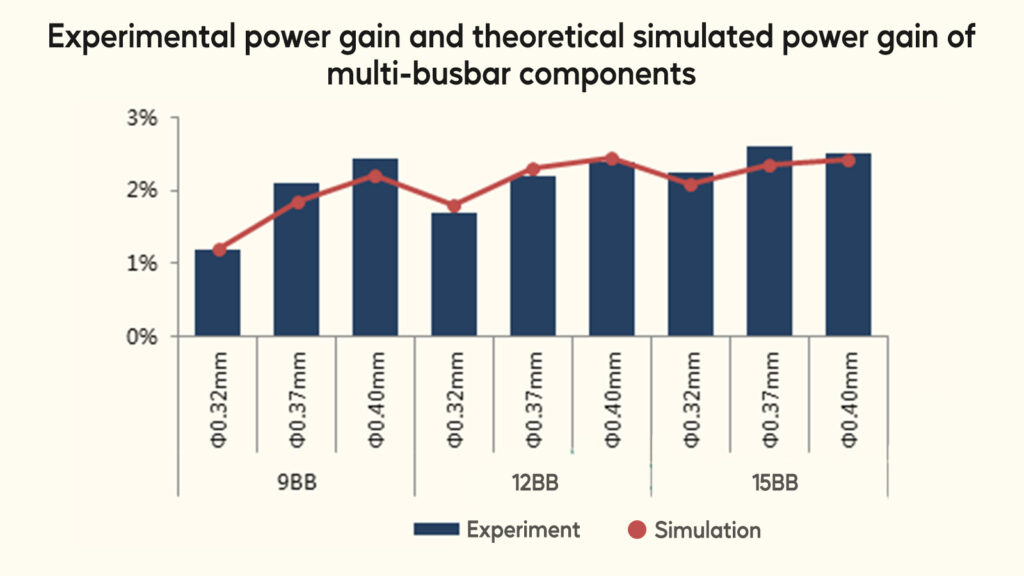

In 2018, with advancements in cell processes and PV ribbon material technologies, the emergence of MBB (Multi-Busbar, 9-15 busbars) technology marked a turning point. Solar panel manufacturers widely adopted circular MBB ribbon welding process technology with a diameter of 0.3-0.4 mm, leading to a substantial boost in cell efficiency.

By 2022, SMBB (Super Multi Busbar, 16-20 busbars) is gradually being applied on top of MBB technology, which uses finer, more numerous, and denser busbars and circular ribbons with diameters of 0.24-0.0 mm. This technology is used in both HJT cells and N-Type TOPCon cells, where the additional busbars provide more current paths, lowering the electrical resistance, and further improving the efficiency of the solar cell.

MBB Technology VS Traditional “More-Busbars”

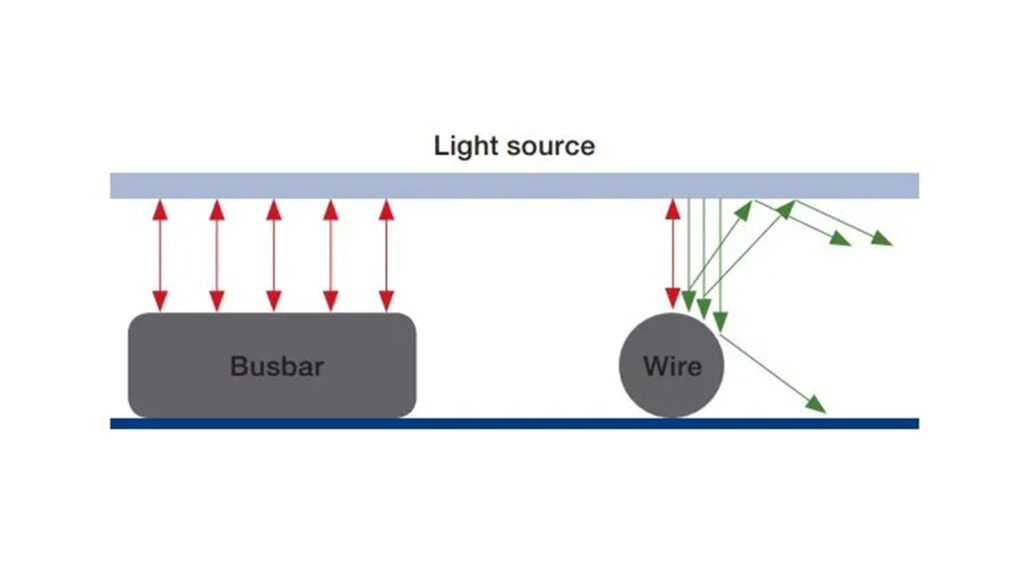

The distinction between the MBB approach and the more traditional “more-busbars” approach lies in cross-section and function. Busbars, typically printed flat, necessitate soldered flat ribbons to carry current away from the cell, introducing more shading and resistive losses. In contrast, MBB utilizes thin, rounded copper wires that don’t require ribbons across the solar cell. These wires carry current from the fingers to interconnecting ribbons outside the cell’s front surface. As depicted in Image 2, their rounded cross-section enhances optical performance, allowing more light to reflect onto the solar cell. Super Multi Busbar (SMBB) technology takes these advancements further. SMBB builds upon the MBB approach by incorporating an even greater number of busbars, usually between 16 and 20. This improvement further reduces shadow shading, optimises the current collection path and reduces resistance, thus improving the performance of the solar cell, especially under partially shaded conditions.

What are the Performance Advantages of SMBB Solar Cells?

Improving the efficiency of power generation

SMBB (Super Multi Busbar) technology achieves better shading of the busbars and shorter current transmission distances by adopting finer busbars and reducing the amount of silver paste used. This effectively reduces the series resistance, improves the current collection capability, and further enhances the tolerance of solar cells to microcracks, busbar breaks, and fractures, thereby increasing reliability. As a result, the output power of solar panels is increased by 2%. In addition, circular ribbon soldering technology can enhance the light-reflection ability of the busbars, further boosting the power output of the solar cells.

Reduced series resistance losses

The incorporation of multiple busbars in SMBB cells minimizes series resistance losses, thereby optimizing overall performance and boosting the energy yield of the solar panels. The SMBB process can shorten the current conduction distance from the sub-busbar to the main busbar and reduce the series resistance loss by 15%.

Increasing the bifaciality

As the adoption of bifacial technology continues to grow worldwide, the incorporation of Simultaneous Super Multiple Busbar (SMBB) technology emerges as a promising avenue to enhance the bifaciality of solar cells. Bifaciality, representing the ratio of front power to rear power, stands as a crucial metric for solar cell efficiency. The utilization of SMBB brings a notable advantage by enabling the printing of smaller rear aluminum fingers. This strategic adjustment minimizes shading on the rear side of the cell, thereby significantly improving the bifacial light harvesting capability of the solar cell. The integration of SMBB technology showcases a forward step in advancing the overall performance and efficiency of bifacial solar cells.

Reducing production costs

A substantial cost component in solar cell manufacturing is attributed to the screen-printed silver (Ag) front-side metallization process. In recent years, the optimization of the less busbar cell design has been achieved by incorporating additional busbars into the device. This strategic modification, involving variations in the number and geometry of the busbars, results in a noteworthy reduction in Ag paste consumption while concurrently enhancing module efficiency. Furthermore, a further reduction in silver usage is attainable by substituting the rear-side Ag/Al pads with tin pads during the soldering process. These alterations, integral to the Super Multi Busbar (SMBB) approach in solar cell design, not only contribute to significant cost savings in the metallization process but also lead to an improvement in the efficiency of solar panels.

Minimized shading impact

SMBB technology can minimize shading impact on solar panels. In traditional designs, shading on a single busbar could significantly affect the entire module’s performance. SMBB solar cells distribute multiple current paths, minimizing the impact of shading and improving overall system efficiency. This heightened tolerance to shading proves particularly advantageous in installations where objects such as trees or buildings may cast partial shadows, potentially affecting the performance of solar panels. The numerous slender busbars in SMBB solar cells establish multiple routes for electrical current, rendering them more resilient to power losses induced by partial shading.

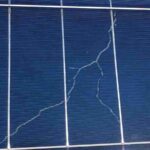

Reducing the effects of microcracks

Super Multi-Busbar (SMBB) solar cells offer significant advantages in mitigating the effects of microcracks as well as those produced by broken busbars. This is because SMBB increases the chances of cracked parts of the cell maintaining electrical contact with the rest of the cell. SMBB solar cells use multiple fine current transmission paths, which allow them to more flexibly adapt to microcracks or broken gates on solar panels. Microcracks, when they occur, tend to be confined to smaller areas on the solar panel, thanks to the increased number of busbars in SMBB technology. This stands as a substantial improvement over earlier designs with fewer busbars. By limiting the spread and impact of microcracks, SMBB solar cells contribute to enhanced durability and reliability of solar panels, ensuring more robust performance over time. This added resilience is particularly significant in challenging environmental conditions, making SMBB technology a valuable advancement in solar cell design.

Reduced hotspots

Mitigate the occurrence of hotspots with SMBB technology, which ensures a uniform distribution of electrical current across the cell surface. This minimizes the risk of localized heating caused by high resistance. Hotspots, known for compromising efficiency and inducing long-term cell degradation, are effectively addressed through the application of SMBB technology.

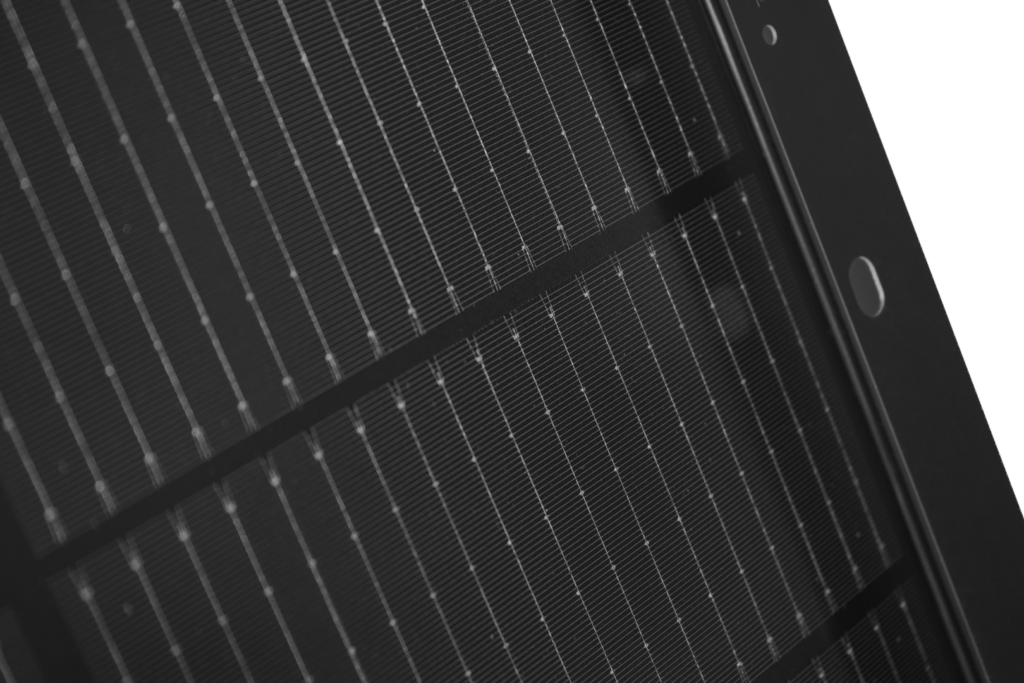

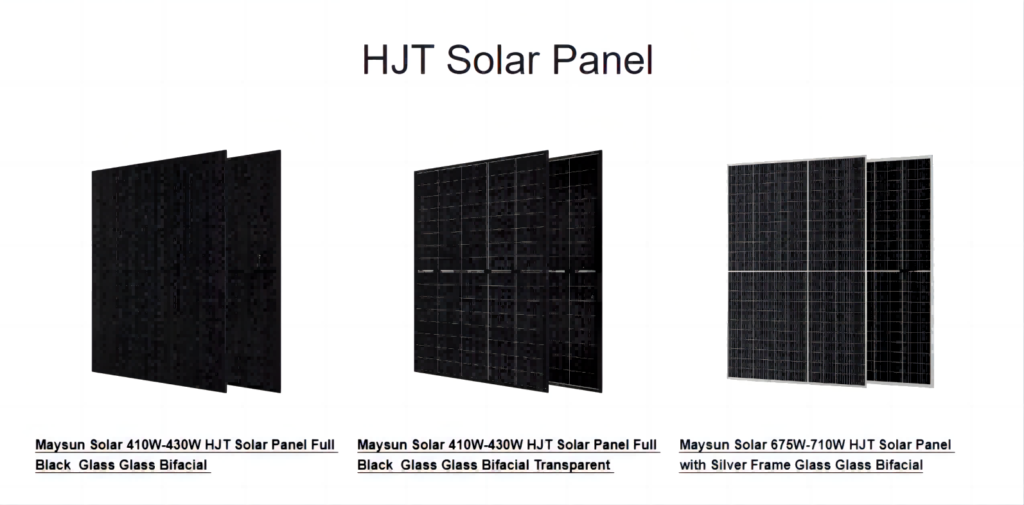

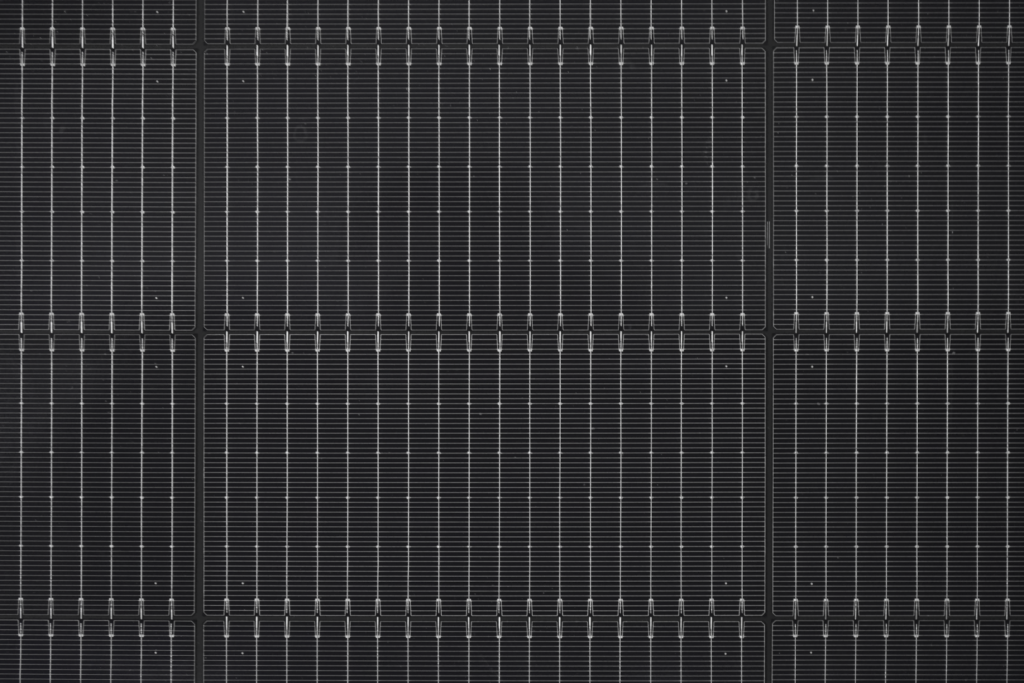

Maysun Solar’s HJT solar panels are a typical example of solar panels using SMBB technology. They have more and thinner busbars, with 18 busbars per cell, reducing silver paste consumption and minimising shading. This not only shortens current transmission distances but also enhances tolerance to microcracks and broken busbars. Elevate your solar experience with Maysun Solar, where reliability meets innovation. Below is the picture of our HJT solar panels, click the button below to learn more about Maysun Solar’s HJT solar panels!

The symmetrical structure of HJT solar panels, a typical example of SMBB technology, optimises bifacial power generation, an innovative technology that captures sunlight from both the front and the back to increase overall power generation. This innovative technology captures sunlight from both the front and the back, thus increasing the overall power generation capacity.HJT solar panels can be widely used in agricultural photovoltaics, carport photovoltaics, and fence photovoltaics scenarios that require bifacial power generation.

Conclusion

In summary, SMBB technology is poised to drive future trends in the solar energy industry, characterized by increased energy efficiency, reduced production costs, enhanced reliability, widespread adoption, strengthened photovoltaic innovation, and adaptability to diverse environments. This design, achieved through minimizing internal resistance losses, reducing silver paste consumption, and mitigating overheating risks, demonstrates outstanding performance across various environmental conditions. The continuous innovation in SMBB technology holds the potential to propel developments in the clean energy sector, providing more sustainable solar solutions for the future.

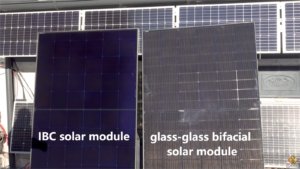

Maysun Solar has been dedicated to manufacturing top-tier photovoltaic modules since 2008. Explore our extensive range of solar panels, including full black, black frame, silver, and glass-glass options, all incorporating cutting-edge technologies such as half-cut, MBB, IBC, HJT, and Shingled. These panels are designed for superior performance and boast stylish aesthetics that seamlessly integrate with any architectural setting. Maysun Solar has successfully established offices, warehouses, and enduring partnerships with skilled installers across numerous countries. For the latest module quotations or any inquiries related to photovoltaics, please feel free to reach out. We are eager to assist you in harnessing the power of solar energy.

New Photovoltaic news you should know about (March 2024)

Table of Contents REC Unveils a 430 W Heterojunction Solar Module Boasting 22.2% Efficiency REC, a Singapore-based PV module manufacturer, introduces its residential solar modules featuring Alpha heterojunction cell technology. Production has commenced at REC’s Industry 4.0 fab in Singapore, with initial shipments

IBC Solar Modules vs. Bifacial Glass-Glass Solar Modules: Which Is More Suitable for Winter or Low-Light Conditions?

Table of Contents Introduction As the demand for renewable energy continues to surge, advancements in solar technology have broadened the spectrum of component choices available to us. Among these, IBC (Interdigitated Back Contact) full black solar modules have garnered special attention due to

Why Are Lightweight Bifacial Solar Panels the Best Choice for Balcony Solar Power Plants?

Table of Contents In the quest for efficient and eco-friendly home energy solutions, solar photovoltaic technology has emerged as a key player due to its sustainability and clean energy benefits. Particularly in the space-constrained urban settings, the effective conversion of every inch of

Questions You Might Ask About Balcony Solar Power Plants in 2024

Table of Contents What is a Balcony Solar Power Plant? Similar to a traditional photovoltaic panel, a Balcony Solar Power Plant is a device designed to generate electricity from solar energy. This green energy generator is specifically tailored for self-consumption, but it comes with

A Step-by-Step DTU Guide for Balcony Solar Power Plants

As renewable energy becomes increasingly integral in our daily lives, Maysun Solar’s Balcony Solar Power Station, with its advanced technology and user-friendly design, represents a transformative approach to home solar solutions. The integration of a Data Transfer Unit (DTU) enhances its smart functionality

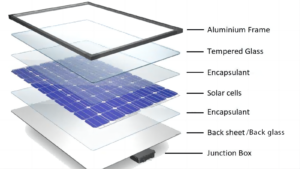

What Are The Main Components of Solar Panels?

What are the main components of solar panel? Solar panels, the cornerstone of solar energy technology, are composed of several integral parts, each contributing to their ability to harness sunlight and convert it into electrical energy. In this article, we will explore the essential