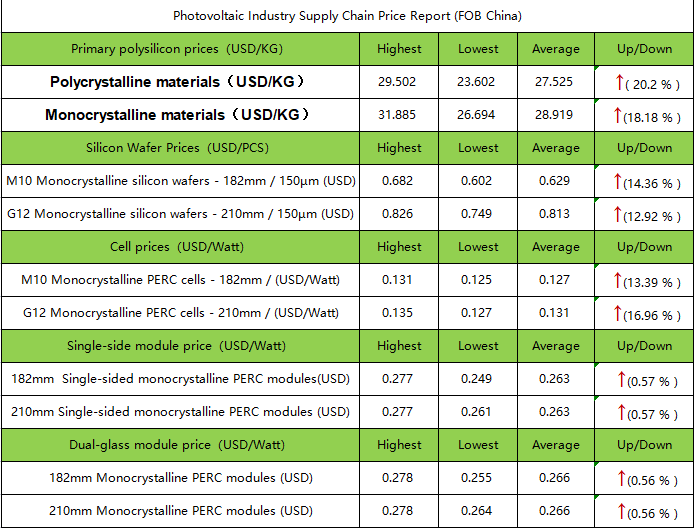

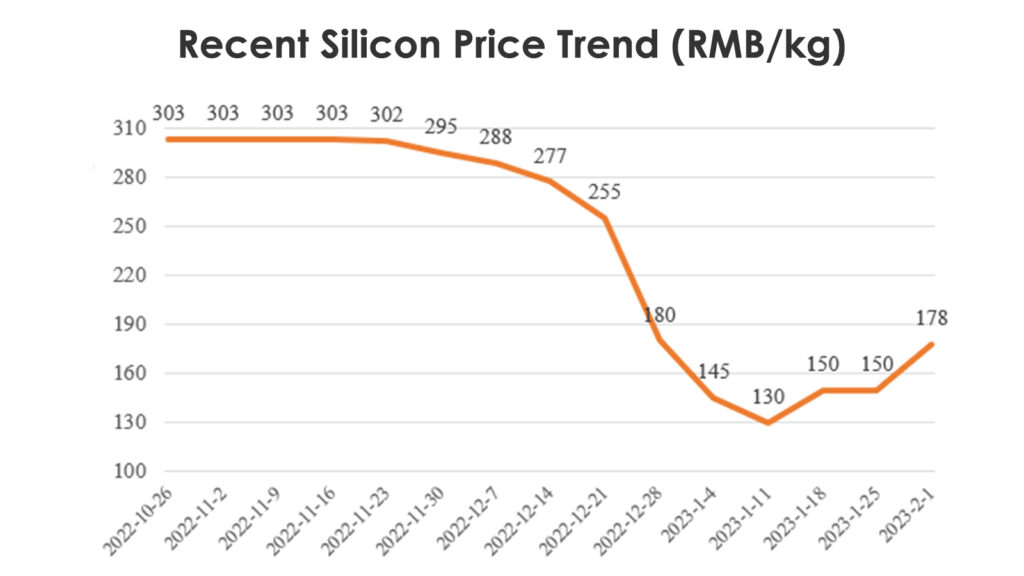

On the eve of the Chinese New Year, the photovoltaic industry chain experienced a panic-stricken sharp drop. The price of silicon material fell from the highest point of US$45.6/kg to nearly US$20/kg, a drop of more than 56%. At the same time, the prices of silicon wafers and cells also fell. There have been sharp price cuts. At that time, we believed that this was a panic-like and irrational decline. This kind of market is destined to be short-lived, and the price of the photovoltaic industry chain will rebound soon. The latest price published by PVInfolink this week verified our prediction: since February, the price of the entire photovoltaic industry chain has rebounded across the board.

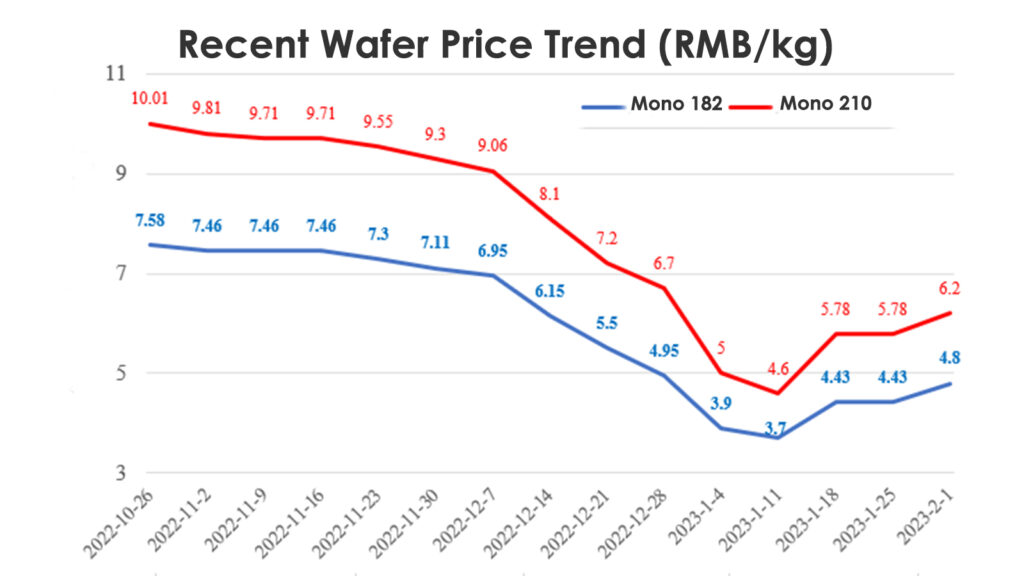

Prices of silicon materials, silicon wafers, and cells rebounded V-shaped

With the end of the holiday, market demand has gradually picked up, and the prices of silicon materials and silicon wafers have stepped out of a deep “V” upward trend, as shown in the figure below. According to the silicon material price data released by the China Silicon Industry Branch, the price of monocrystalline silicon re-feeding increased to US$32.5/kg this week, a month-on-month increase of 31%. This week’s cell price increase has reached about 14%. In this regard, we regard this increase as a restoration of the value of photovoltaic products.

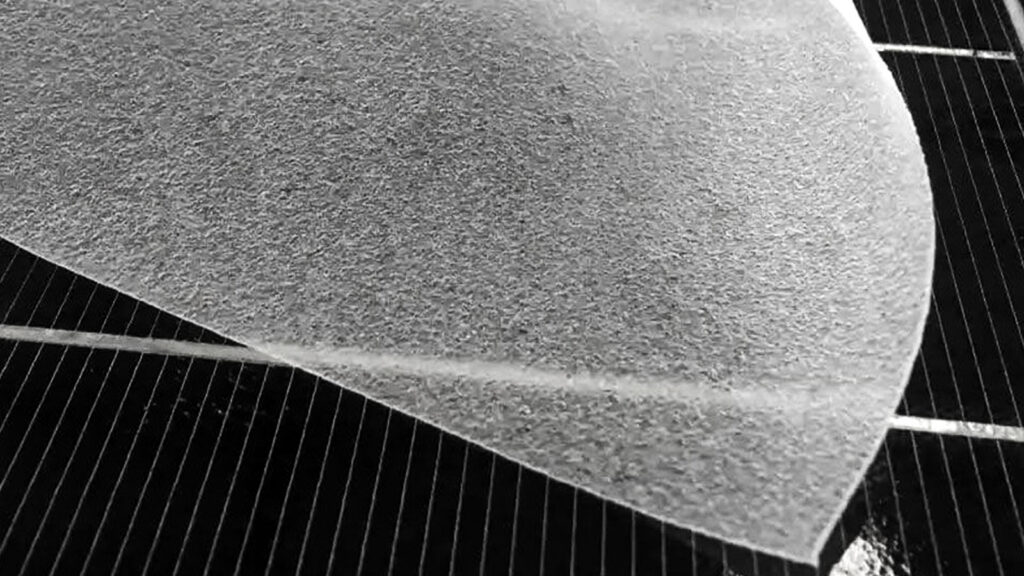

The price of auxiliary materials for photovoltaic modules has risen

This week, the price of photovoltaic auxiliary materials also rose. Represented by EVA film, the mainstream price is raised by 10%. On January 31, a photovoltaic film (EVA) company issued the “Price Adjustment Notice”, stating that due to the recent continuous rise in the price of EVA raw materials, the company’s product costs have continued to increase, and the company has decided to start adjusting the original price of the EVA film. up 10 percent.

Component prices remain unchanged

In 2023, the demand for photovoltaic development in countries around the world is still very strong, and the order volume of major photovoltaic module companies has increased significantly in February and March. The huge demand has kept the module price in a reasonable price range, even in the period before the price of silicon material fell sharply.

Future Price Prediction

The price increase of silicon wafers this time is mainly due to the extremely tight supply of silicon wafers. Some battery chip companies say that the current purchase of silicon chips depends on robbing! The tight supply of silicon wafers is mainly caused by the following reasons:1) Due to the sharp drop in the price of silicon wafers, silicon wafer companies have drastically reduced their inventories, resulting in lower silicon wafer inventories than normal.

2) Due to the drastic price changes, the transaction volume of silicon materials is very small. After the digestion of the Chinese New Year holiday, the current silicon wafer companies generally lack silicon material production, and the output of silicon wafers is lower than expected;

3) At present, the quotation of polysilicon materials has increased to more than 32 US dollars/kg. Due to the unstable price, the transaction volume of polysilicon materials is still not large! Even if there is a deal immediately, it will take 2-3 weeks to produce silicon wafers from silicon materials;

4) The downstream demand is strong, resulting in a substantial increase in the demand for upstream cells and silicon wafers. Due to the shortage of upstream silicon wafers, the supply of solar cells has been tight, and the solar cells have risen all the way from the lowest US$0.11/W to US$0.14/W.

It can be seen that the downstream demand has risen, but the upstream needs a production cycle. Therefore, it is expected that the supply of silicon wafers will be in a state of tightness throughout February, and it will not be gradually relieved until early March.

In the later stage, with the release of silicon material production capacity and the increase in the operating rate of silicon wafer companies, the supply and demand of the industry will gradually tend to balance, and the price will stabilize at the general acceptance of terminal demand for component prices.

Installing photovoltaics is the right choice for every family, sooner rather than later. Since its establishment in 2008, Maysun solar has been focusing on producing high-quality photovoltaic modules. Contact us to choose the module products that suit you.