Table of Contents

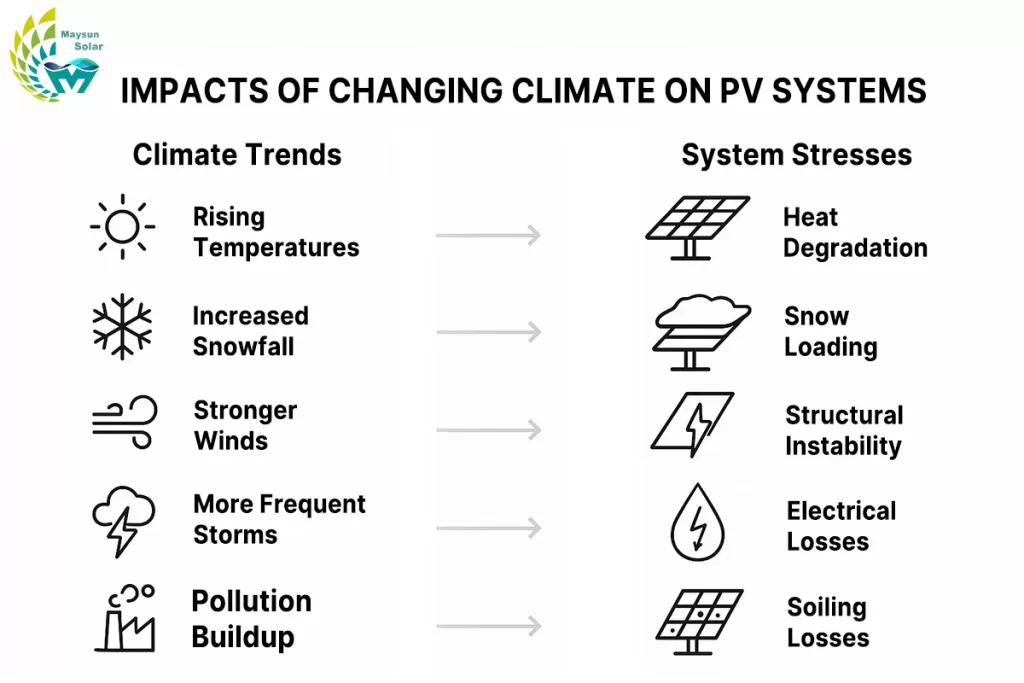

1. Extreme Weather Is Reshaping the Risk Assessment Basis for Commercial PV Deployment

From prolonged heatwaves in southern Italy to heavy snowfall in Germany and northern Europe, and frequent thunderstorms in Spain and France, extreme weather has become a tangible challenge for commercial and industrial PV deployment across Europe over the past three years. According to 2024 data from the European Environment Agency (EEA), extreme heat events in southern Europe have increased by 54% over the past five years, while thunderstorm days in central and western Europe have risen by more than 30%.

Climate volatility has evolved from an operational risk into a threshold for project feasibility. The logic behind PV deployment is shifting—from relying on electricity subsidies to focusing on the system’s structural resilience against climate stress.

Frequent occurrences of thermal degradation, snow-induced deformation, and lightning-related disconnections not only reduce energy output but also cause delays in grid connection, loss of incentives, and asset depreciation. The pressure resistance of a PV system is now directly linked to its adaptability to external climate conditions, significantly impacting the overall return stability of the project.

At the same time, regulatory frameworks in Europe are becoming stricter. Since 2024, France’s RT2020 green building standard has incorporated PV systems’ wind and snow resistance into building energy performance evaluations, making it a prerequisite for approval. In high-risk areas, projects that fail to meet structural load-bearing requirements may be rejected or denied insurance.

As a result, the deployment logic of PV systems is shifting toward structural adaptability, which has become essential for evaluating their long-term value. To determine whether a system is structurally suitable, companies must first understand how extreme weather will affect it.

2. Five Structural Shocks Facing Commercial PV Systems Under Extreme Weather

Five Structural Impacts of Extreme Weather and Design Response Strategies

| Type of Extreme Weather | Primary Structural Impact | High-Risk Areas | Key Design Responses |

|---|---|---|---|

| High Temperature | Thermal degradation, structural expansion/contraction | Southern Europe, light-colored metal roofs | Low temperature coefficient modules, ventilated back panels, thermal diffusion design |

| Heavy Snow | Concentrated snow load, glass cracking | Northern Europe, large-span roofs in mountainous areas | Snow load simulation, structural reinforcement, dual-glass high snow load modules |

| Strong Wind | Uplift damage, anchor loosening | Northern German plains, western France, coastal areas | Zone-based anchoring, chemical anchors, optimized edge module layout |

| Smog Pollution | Light attenuation, hotspot formation | Industrial zones, urban rooftops | Anti-pollution coated modules, cleaning mechanisms, pressure differential control |

| Thunderstorm & High Humidity | PID, electrical faults, moisture ingress | Coastal areas, regions with frequent thunderstorms | IP68-encapsulated modules, grounding and SPD systems, waterproof structural design |

Note This table is based on typical European climate zones (EEA 2024) and photovoltaic engineering practices, suitable for early-stage technical planning and structural suitability assessments.

High Temperatures: Beyond Thermal Degradation, Structural Stress Imbalance Is the Real Concern

Performance degradation caused by high temperatures is not the only risk. When operating above 65°C, modules with a higher temperature coefficient can experience an annual output deviation of 10–15%. At the same time, thermal expansion and contraction can cause long-term stress on structural points such as frames, connectors, and cable interfaces, leading to micro-shifts and fatigue issues.

These thermal risks are further amplified under conditions of poor ventilation, low thermal conductivity, or rooftops made of reflective materials like color-coated steel or light-colored surfaces.

During the system design phase, companies should assess rooftop thermal load characteristics and prioritize modules with low temperature coefficients, along with implementing ventilated back panels or thermal diffusion designs to mitigate structural stress.

Heavy Snow: Static Load Risks Go Beyond Roof Collapse

Heavy snow not only tests the load-bearing capacity of mounting structures but can also lead to frame cracking, glass deformation, and encapsulant tearing, especially in northern Europe and mountainous areas with wide-span rooftops. The commonly referenced 5400 Pa is merely a static load standard and does not account for cyclical loading or edge concentration.

For systems deployed at high altitudes, north-facing roofs, or in areas with structural obstructions, localized snow load concentrations must be evaluated.

It is recommended to include snow load simulation maps during structural design and to reinforce edge modules accordingly. In high-risk areas, using dual-glass modules designed for heavy snow loads can improve overall pressure resistance.

Strong Winds: Dynamic Loads Can Easily Get Out of Control at the Roof Edges

Wind pressure is often underestimated, particularly in high-wind zones such as the North Sea coast, western France, and the eastern Mediterranean. Large rooftop projects in these areas are prone to edge lift effects caused by turbulence, leading to module detachment, rail breakage, and displacement of mounting connections.

Wind pressure is not uniformly distributed but increases significantly depending on roof location. In Zone 3 (rooftop corners and edges), wind loads can be 2–3 times higher than in central areas. Therefore, mounting and module layout must be designed by zone.

This risk is even more pronounced on metal roofs, aged rooftops, or uneven slopes.

During structural design, EPCs should apply zoned load models, prioritize the use of reinforced anti-uplift mounting systems (e.g., C-channel steel, double-rail ballast systems) at the edges and corners, and employ chemical anchors or pressure-bonded connections.

Smog and Pollution: Light Attenuation and Hot Spot Formation Are Often Overlooked

Dust and pollutants accumulating on modules in industrial zones and urban rooftops reduce light transmittance, impacting performance under low light and causing hot spots. Once hot spots form, microcracks and structural damage to the glass may occur, potentially resulting in encapsulant failure.

Prolonged pollution buildup increases cleaning frequency and OPEX, and exacerbates the risk of hot spots.

For deployments in central European industrial zones or near high-pollution sources, it is advisable to use modules with anti-soiling coatings, establish a regular cleaning schedule, and design systems with optimized string voltage balance to reduce mismatch effects.

Thunderstorms and High Humidity: PID and Waterproofing Are the Bottom Line for System Safety

High humidity and frequent lightning events pose serious threats to the electrical stability of PV systems, leading to leakage currents, potential imbalances, and inverter failures. The PID effect (Potential Induced Degradation) is especially pronounced during humid nights, affecting output and accelerating degradation.

Standard encapsulation does not equate to full protection—cable connectors, junction boxes, and glass edges are all high-risk points for water ingress.

For projects in high-humidity or lightning-prone regions, grounding systems must comply with IEC 60364 lightning protection standards, and modules should meet IP68 and PID resistance certifications. SPDs (Surge Protection Devices) should be considered the minimum requirement in high-risk zones to prevent fault amplification.

3. Five Core Adaptation Capabilities PV Modules Must Have Under Extreme Weather

The stability of a PV system under extreme weather conditions depends not only on total energy yield but also on whether the modules possess structural resistance capabilities. The ability to withstand multiple climate cycles—wind loads, thermal expansion, lightning, snow pressure, and pollution—while maintaining physical integrity and consistent power output is essential.

In light of current climate trends, companies must rely on quantifiable engineering indicators when selecting reliable PV modules.

Comparison of Structure and Environmental Adaptability Parameters of Three Main High-Performance Module Types

| Parameter | IBC | TOPCon | HJT |

|---|---|---|---|

| Appearance Design | No front busbars, all-black aesthetic | Dual-glass encapsulation, various looks available | Bifacial dual-glass, all-black optional |

| Temperature Coefficient (%/°C) | –0.29% | –0.32% | –0.243% |

| First-Year Power Degradation | 1.5% | 1.5% | 1.0% |

| Annual Average Degradation Rate | 0.4% | 0.4% | 0.35% |

| Conversion Efficiency Range | 20.8%–23.2% | 21.5%–23.22% | 21.7%–22.87% |

| Bifaciality | Not applicable | Approx. 85% | Approx. 95% |

Note Data is sourced from Maysun Solar’s official website module specifications and is for preliminary technical selection only. Final specifications should be confirmed based on the actual product series.

High-Temperature Adaptability: Is the Temperature Coefficient Within Standard?

The temperature coefficient indicates how much a module’s power output drops for every 1°C increase in temperature. In high-temperature environments—such as southern or central-eastern Europe—this metric directly affects summer energy output deviation.

Mainstream PERC modules typically have a coefficient of –0.35%/°C, while TOPCon averages around –0.32%/°C. HJT and IBC modules perform better, with values as low as –0.29%/°C and –0.243%/°C, respectively. At 65°C operating temperature, a 0.01% reduction in the coefficient can reduce annual generation loss by approximately 0.25–0.4%.

For systems deployed without rear ventilation, on light-colored rooftops, or in heat island zones, temperature mismatches can amplify output fluctuations.

Enterprises should treat a coefficient of ≤–0.30%/°C as the minimum standard for deployments in hot regions to avoid over-reliance on nominal efficiency at the cost of stable output.

Load-Bearing Capacity: Physical Stability Under Structural Stress

Modules must withstand both snow and wind loads. A static snow load capacity of 5400 Pa is considered a high-safety standard, and wind load resistance of 2400 Pa or higher is recommended under EN 1991-1-3 and IEC 61215 structural safety standards in the EU.

However, these values must be matched with actual rooftop wind load zones. In Zone 3, wind pressure at corners may be 2–3 times higher than in central zones. If racking systems are not graded by zone, it can lead to loosened edges or rail fractures.

Standard encapsulation does not equal universal compatibility. On sloped roofs, old steel structures, or high-snow-load regions, using modules with inadequate strength significantly increases maintenance frequency.

When assessing static load performance, companies should apply an integrated model combining “5400 Pa + zonal wind load simulation + racking material” to ensure system safety.

Electrical Protection: System Integrity in Humid and Storm-Prone Conditions

PID (Potential-Induced Degradation) is a rapid loss of performance in modules caused by reverse voltage and high humidity, especially at night. In areas with frequent lightning or poor grounding, modules may show output drops, leakage currents, and string mismatches within 2–3 years.

High-quality modules should pass IEC TS 62804 PID and damp heat aging tests, with an IP68 or higher encapsulation rating—especially for coastal, storm-prone, or industrial humid environments.

Some low-cost modules may claim PID resistance but often fail under prolonged voltage and moisture stress.

In humid regions, PID resistance and IP protection level must be included in the combined assessment of grounding and inverter SPD systems, and considered a compliance requirement for insurance.

Low-Light Adaptability: Ensuring Output in Shade and Smog Conditions

In conditions such as smog, overcast skies, high latitudes, or suboptimal sun angles, low-light responsiveness determines actual usable system hours. This performance largely depends on cell architecture and metal shading path design.

IBC modules, with no front busbars, offer a broader spectral response and better reaction to steep incident angles, making them ideal for mornings, evenings, or shifting shadows.

HJT modules, thanks to their passivated structure and carrier retention ability, also outperform TOPCon and PERC under weak light.

For systems near industrial zones or traffic-heavy areas, modules with certified low-light performance, such as IBC or HJT, are recommended. Proper layout design should also be implemented to optimize shading response and reduce risks of hot spots and power loss.

Encapsulation Longevity: Resistance to Thermal Cycling and Aging

The encapsulation materials of a module determine its structural stability over a 20–25 year lifespan. In environments with frequent thermal cycling, strong wind disturbances, or irregular rooftop structures, the fatigue life of frames, sealants, and cable interfaces directly affects consistency in energy generation.

POE encapsulants offer better aging resistance than traditional EVA, while dual-glass modules significantly reduce water vapor permeability and UV degradation. In addition, frame thickness, seal design, and lamination processes are all critical to long-term physical stability.

Premium module suppliers typically offer 25-year linear performance warranties, supported by UV aging, damp heat, salt mist, and tensile stress tests, helping prevent reactive maintenance in later years.

4. Module Configuration Logic for Different Scenarios: From Heat to Heavy Load

The reliability of a PV system depends not only on the performance of its modules but also on how well those modules are suited to specific application scenarios. Regional climate, rooftop structure, and project purpose determine that component configuration strategies must be adapted to local conditions and practical needs.

High-Temperature, High-Radiation Regions: Low Temperature Coefficient Modules for Stable Summer Output

In Mediterranean regions such as southern Italy, Spain, and Greece, summer heat is prolonged, rooftop thermal loads are high, and ambient temperatures frequently exceed 40°C, with module surface temperatures often rising above 65°C. Under such conditions, systems operate long-term outside their ideal thermal range. Modules with high temperature coefficients can significantly reduce overall power generation, affecting the stability of project returns.

For these conditions, HJT modules, with a low temperature coefficient of –0.24%/°C, are a reliable choice to control thermal degradation and maintain long-term output stability. They are well-suited for business projects that prioritize consistent performance and operational reliability.

Heavy Snow Load Regions: Reinforced Modules to Handle Concentrated Snow Loads

In regions like northern Europe, the Alps, or southern Germany, winter snowfall is heavy and unevenly distributed on rooftops. This often causes localized stress on racking systems, leading to glass deformation or frame cracking. Especially on large-span sloped roofs or industrial buildings, day–night temperature cycles intensify thermal expansion and fatigue, making load-bearing capacity a critical success factor.

In these environments, reinforced TOPCon modules are recommended for their high structural integrity. With only 1.5% power degradation in the first year and 88.9% capacity retention after 25 years, they demonstrate excellent long-term stability and structural adaptation under heavy snow conditions.

Light Structures and Aesthetic Integration: Full Black Modules Balancing Appearance and Load Control

On office buildings, corporate headquarters, or architectural showcase facilities, PV systems often need to meet both aesthetic integration and rooftop load limitations. In lightweight steel structures, color-coated metal roofs, or BIPV designs, module visual consistency, weight, and electrical performance must be closely aligned.

IBC full-black modules perform exceptionally well in these scenarios. Their busbar-free front side increases light absorption by approximately 2.5%, and their weight of around 20.8 kg makes them lighter than standard dual-glass modules—reducing structural stress and additional reinforcement costs. With a maximum conversion efficiency of 22.5%, they ensure high output while maintaining a refined appearance, ideal for projects sensitive to both design and structural factors.

Agricultural and Light-Transmitting Structures: Flexibility and Size Compatibility Come First

In semi-open structures like greenhouses, sunshades, and carports, PV modules must balance transparency and energy generation, while offering enough structural flexibility to adapt to wide spans and irregular layouts. These environments typically limit reinforcement upgrades, so installation compatibility and dimensional fit become key concerns.

For these cases, large-format TOPCon modules offer high power output and structural adaptability, with a maximum capacity of 595W and 23.04% conversion efficiency. Their dual-glass encapsulation provides greater airtightness and mechanical strength, helping reduce failure rates in high-temperature, high-humidity agricultural settings, while enhancing system longevity and stability.

Polluted and Corrosive Environments: Dual-Glass Modules to Strengthen Sealing and Weather Resistance

In industrial zones, chemical plants, or coastal areas with high salt content, modules must withstand UV radiation, wind erosion, and corrosive gases over the long term. These conditions accelerate material aging, especially at junction boxes, frames, and seal points, increasing the risk of moisture ingress and hot spot formation—ultimately threatening system safety and stability.

For such environments, TOPCon modules with dual-glass encapsulation are ideal. They excel in sealing performance and climate resistance, effectively resisting salt mist, ammonia, and other corrosive elements. This delays material degradation and reduces power loss. Compared to traditional single-glass modules, dual-glass structures provide superior structural durability under prolonged exposure to humidity and corrosive stress—making them suitable for high-pollution, high-moisture deployment scenarios.

5. System-Level Disaster Resilience for Commercial PV: From Mounting Structures to O&M

In the face of increasingly frequent extreme weather events, establishing a comprehensive disaster resilience strategy—spanning structure, protection, monitoring, and maintenance—is essential for ensuring the stable operation of commercial PV systems. Through multiple defense layers, businesses can effectively reduce climate-related risks and secure consistent power generation and investment returns.

High-Wind Areas: Reinforced Anchoring to Prevent Wind-Induced Structural Failures

In regions prone to typhoons or intense gusts—such as Sicily in Italy, the southern coast of France, or the North German plains—wind loads are a primary cause of system damage. Data shows that when gust speeds exceed 35 m/s, the tearing rate of traditional mechanical mountings can increase by up to four times compared to standard conditions, with rooftop edges and corners being the most vulnerable.

For such environments, aluminum-magnesium-zinc or stainless steel C-channel supports, combined with chemical anchors or embedded reinforcements, should be used. Wind tunnel tests can help optimize array layouts to reduce edge wind pressure buildup. Field data indicates that structural reinforcement and denser fixing points can reduce wind-related failure rates to below 0.1%.

Lightning-Prone Regions: Grounding and Equipotential Bonding as the Safety Baseline

According to the European Meteorological Agency, regions like Italy and southern France experience over 30 thunderstorm days per year. Systems lacking proper grounding are highly vulnerable to lightning damage, including inverter failure, module burnout, and even fire. Inadequate lightning protection—despite low cost—can lead to asset losses in the millions.

Projects in such areas must install grounding copper bars to ensure that each module, rail, and inverter casing is integrated into the grounding network, and all components are connected via a main equipotential terminal to the facility’s lightning protection grid. The DIN EN 62305 standard specifies that for Lightning Protection Level II, grounding resistance should be below 10 ohms. With proper wiring and grounding conductor layout, system tolerance to lightning surges can exceed 20 kA.

Frequent Extreme Weather: Smart Monitoring to Reduce Fault Response Time

Severe weather conditions such as wind, snow, hail, or prolonged heat can significantly affect PV system operation—especially in module interconnections, inverter output, and cable temperature. Without smart systems, the average fault detection time is around 72 hours, risking missed repair windows.

Deploying smart monitoring systems equipped with irradiance, humidity, and wind speed sensors enables fault alerts within 5 minutes of abnormal fluctuation, pinpointing the affected modules. It is recommended to integrate the system with local weather service APIs, allowing for features like automatic off-grid switching during wind events or pre-scheduling maintenance after storms. Field data shows that such systems can reduce average response time from 48 hours to under 6 hours, cutting annual energy loss by over 3%.

High-Elevation and Edge Zones: Installation Details Are Critical to Structural Integrity

After commissioning, damage from wind, water, and thermal expansion is often rooted in poor initial installation. Areas near rooftop edges, eaves, or height differences are particularly vulnerable. Improper module tilt, spacing, or cable routing can lead to uplift, water ingress, and short-circuits.

It is recommended to use frame-reinforced modules in edge zones and reduce wind pressure by increasing clamp points and using rear-facing layouts. On slopes ≥15° or height differences ≥1 m, tiered installation and horizontal buffers are advised to avoid water convergence at module interfaces. In practice, standardized installation can reduce structural failure rates by over 70%.

High-Pollution and High-Humidity Areas: Cleaning and Inspection Impact System Lifespan

In areas with severe industrial emissions or average annual humidity above 75%—such as Italy’s Po Valley or the Belgian coast—encapsulants and junction boxes face accelerated aging. Without regular cleaning and inspection, surface pollutants can trigger hot spots, PID, or even module breakdown.

Businesses should implement precise cleaning and inspection routines: full cleaning at least once per quarter during dusty or rainy seasons, and electrical performance checks every six months. High-risk components like junction boxes and corroded supports should be included in targeted inspections. Studies show that annual cleaning under normal pollution conditions can recover 3%–5% of energy losses, while in heavy pollution zones, routine maintenance can extend system life by 5–8 years.

Conclusion: In the Era of Extreme Weather, PV System Reliability Is the Foundation of Asset Value

As commercial PV adoption scales up across Europe, module efficiency is no longer the sole decision-making criterion.

Instead, climate uncertainty, long-term O&M demands, and structural safety have become central factors in how companies assess the value of a PV system. It is system stability, disaster resilience, and scenario compatibility that determine whether a solar installation can deliver reliable returns over the next 20 years.

Technical specifications alone only tell part of the story. From HJT for high-temperature endurance, to TOPCon for snow load resistance, and IBC for lightweight rooftops—performance differences often stem from subtle mismatches between technology and context. Many system failures do not emerge at the design stage but surface later, due to structural stress limits, installation oversights, or maintenance blind spots.

When planning a commercial or industrial PV project, companies should aim for stable returns across a 20-year lifecycle, integrating structural compatibility, environmental resilience, and post-installation management into their decision-making framework—not simply initial cost.

A truly reliable system is not the one that looks cheapest on paper, but the one that can withstand extreme weather and deliver consistently stable output over time.

Since 2008, Maysun Solar has been both an investor and manufacturer in the photovoltaic industry, providing zero-investment commercial and industrial rooftop solar solutions. With 17 years in the European market and 1.1 GW of installed capacity, we offer fully financed solar projects, allowing businesses to monetize rooftops and reduce energy costs with no upfront investment. Our advanced IBC, HJT and TOPCon panels, and balcony solar stations, ensure high efficiency, durability, and long-term reliability. Maysun Solar handles all approvals, installation, and maintenance, ensuring a seamless, risk-free transition to solar energy while delivering stable returns.

Reference

European Environment Agency. (2024). Climate change impacts and adaptation in Europe – 2024 review. European Environment Agency. https://www.eea.europa.eu/publications/climate-impacts-adaptation-2024

Fraunhofer ISE. (2023). Photovoltaics Report – Update 12/2023. Fraunhofer Institute for Solar Energy Systems ISE. https://www.ise.fraunhofer.de/en/publications/studies/photovoltaics-report.html

International Electrotechnical Commission. (2022). IEC TS 62804-1: Photovoltaic Modules – Potential-Induced Degradation Testing – Part 1: Crystalline Silicon. IEC Standards. https://webstore.iec.ch/publication/67274

PV Evolution Labs. (2024). 2024 PV Module Reliability Scorecard. PVEL LLC. https://www.pvel.com/pv-scorecard/

Bundesnetzagentur. (2024). PV-Zubau und Einspeisevergütung – Auswertung des Marktstammdatenregisters, Stand Q4 2024. Federal Network Agency of Germany. https://www.marktstammdatenregister.de

Recommend Reading

430–460W or 600W+? How Should You Choose Solar Panel Power for Rooftop Projects?

Compares 430–460W solar panels and 600W solar panels in C&I rooftop projects, showing that solar panel selection should prioritise roof compatibility and system stability.

Changes in the European Solar Policy and Market in 2026

Europe’s 2026 solar policy and grid changes are reshaping solar panel selection, shifting project returns towards market-driven mechanisms and highlighting the roles of TOPCon, HJT and IBC solar panels.

Why European EPCs Are Reassessing Large-Format Solar Panels

European EPCs are re-evaluating large-format solar panels. Panel size directly affects installation risk, system compatibility, and solar project ROI stability.

Do Vertical Bifacial Modules Really Deliver Additional Yield?

Vertical bifacial PV systems are gaining increasing attention across Europe. This article explores under what conditions a vertical layout can create additional value, how bifacial gain is influenced by site conditions, and which project types are best suited to this design.

Which rooftop scenarios make 700W+ solar panels a risk?

An analysis of the practical limits of 700W+ high-power solar panels on residential and commercial rooftops, and how space, load capacity, self-consumption and maintenance affect real returns.

February News in the Photovoltaic Industry

February overview of Europe’s photovoltaic market: module price trends, a rebound in the German PPA market, progress in Italian agrivoltaics and regulatory shifts in France, highlighting key industry signals.

I like the valuable information you provide in your articles.

I will bookmark your blog and check again here regularly.

I’m quite sure I will learn a lot of new stuff right here!

Good luck for the next!

Thank you for your kind words. We are committed to delivering valuable technical content to support PV projects in challenging environments. More insights will be published soon.

Remarkable! Its actually amazing paragraph,

I have got much clear idea about from this article.

Thank you for your feedback. We’re glad the article provided you with useful insights into structural risks and component strategies for PV systems. Stay tuned for more updates.

Why viewers still use to read news papers when in this

technological world everything is available on web?

Thank you for your comment. Our goal is to provide practical and technical insights for PV deployment under extreme weather conditions, beyond general web information. We appreciate your interest.