With the advent of IBC, PERC and TOPCon technologies, solar panel production technology has taken a giant leap forward in recent years. Thanks to advances in efficiency, durability and overall performance, solar panels have become a more practical and affordable source of renewable energy. Let’s compare and contrast these three solar cell technologies.

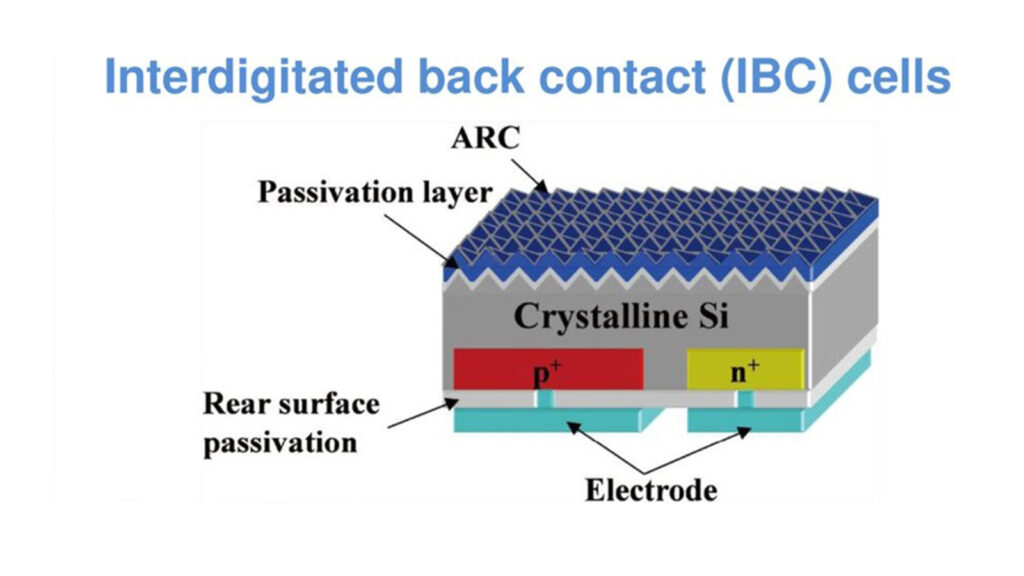

What is IBC technology?

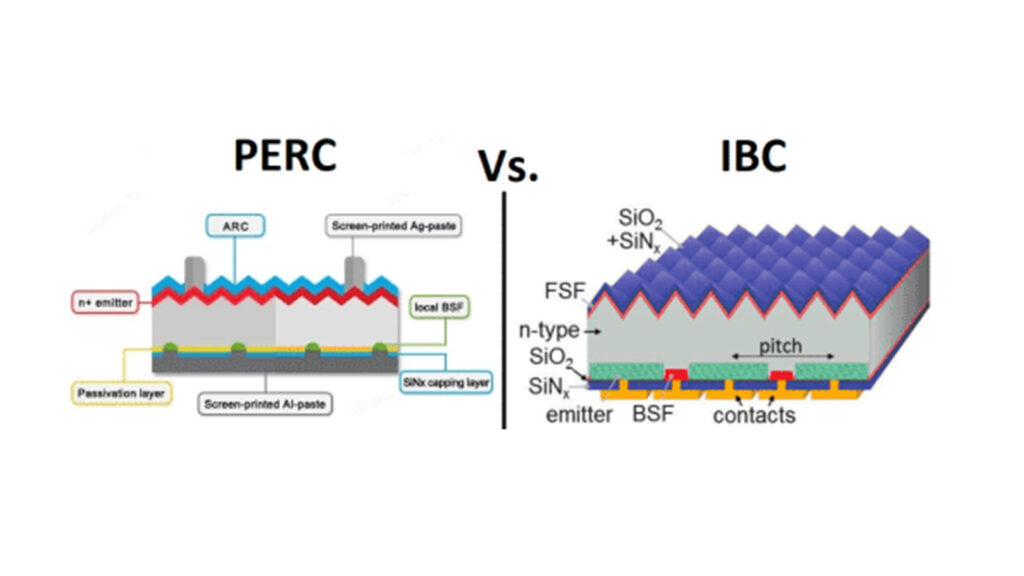

IBC, or Interdigitated Back Contact, is a new type of solar cell technology.The most notable feature of IBC solar cells is that the PN junction and metal contact are located on the back of the solar cell, avoiding the shielding of the front metal grid electrode.

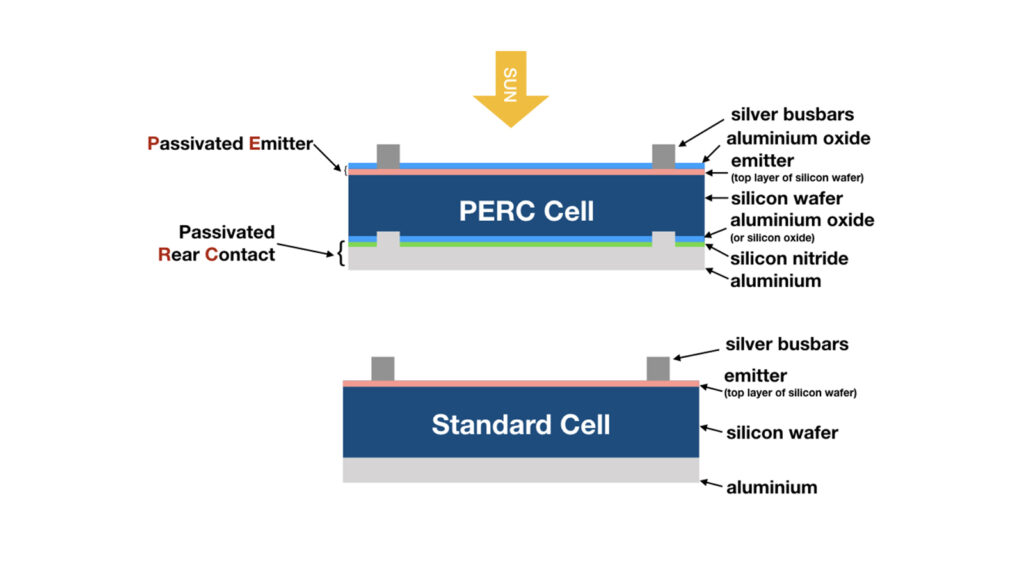

What is PERC technology?

PERC (Passivated Emitter and Rear Cell), this is known as Passivated Emitter and Rear Cell technology, which improves conversion efficiency by adding a dielectric passivation layer to the back of the cell.

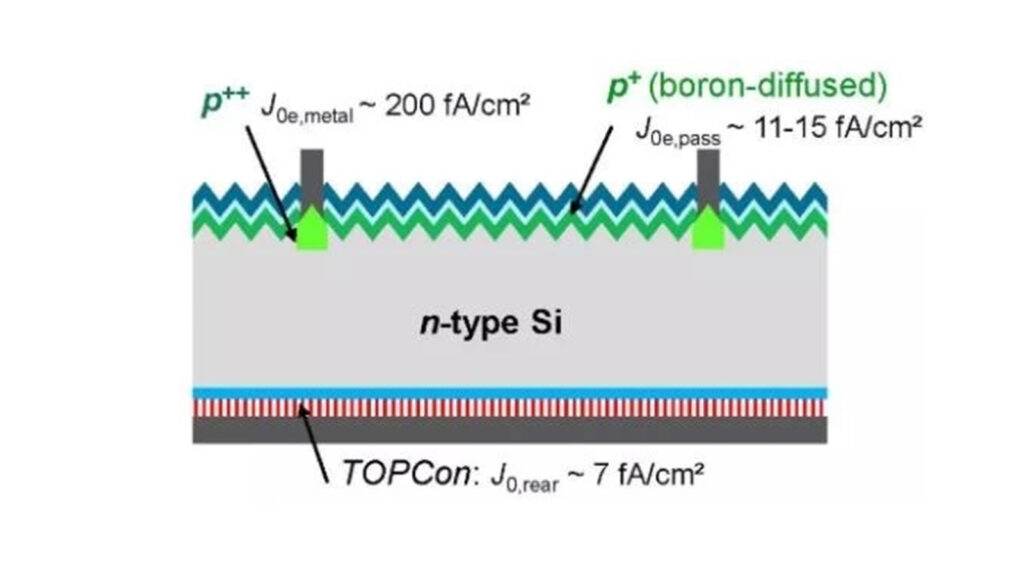

What is TOPCon technology?

TOPCon (Tunnel Oxide Passivated Contact) is a selective carrier solar cell technology based on tunnel oxide passivated contact. It has an N-type silicon substrate cell architecture. On the backside of the cell, an ultra-thin layer of silicon oxide is formed and then a layer of doped silicon is deposited, which together form a passivated contact structure that can improve conversion efficiency.

Comparison of IBC Technology and PERC Technology

Both PERC and IBC technologies have the advantage of increasing efficiency by reducing the amount of space occupied by the grid lines or metal contacts. While PERC technology only reduces the grid lines, IBC solar panel technology completely eliminates the grid lines, thereby expanding the available surface area of the solar panel.

1. Higher efficiency and power output of IBC solar panels

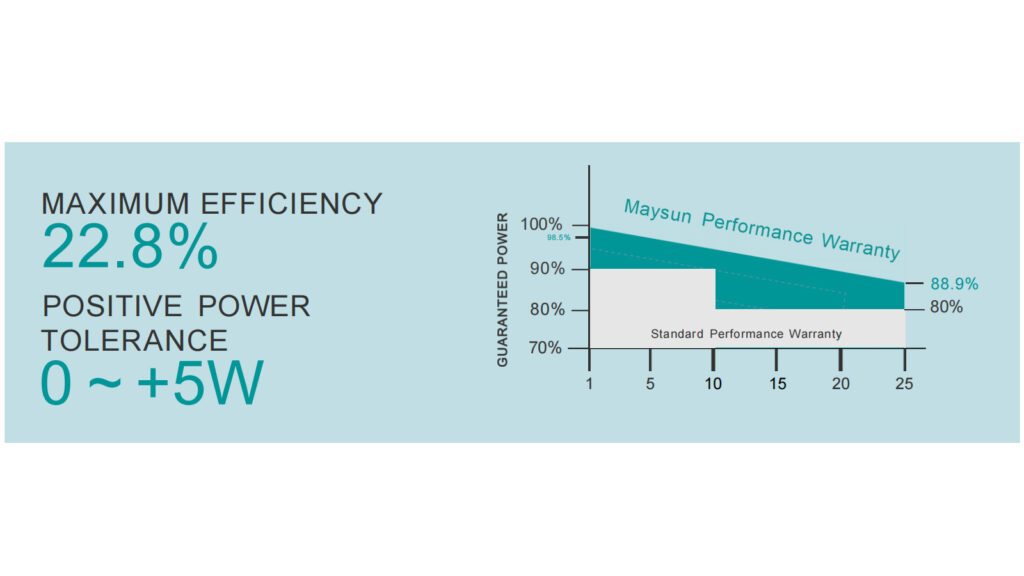

Statistically, the efficiency of PERC solar panels is less than 22%, but the efficiency of IBC solar panel technology has reached a record 22.8%, which indicates that IBC technology is superior to PERC technology. Because the frontal metal connection, which tends to block sunlight, has been removed IBC panels have a larger effective surface area for solar cells.

2. IBC solar panels have better low temperature coefficient

Because the back contact protects the solar cells from moisture and heat, IBC solar panels can work more efficiently in hot climates and have a minimum temperature coefficient of -0.29%/°C when the power is at its peak.

3. IBC solar panels are more aesthetically pleasing

With IBC technology, aesthetics and performance go hand in hand. Unlike PERC panels, IBC panels have no frontal metal contacts for an elegant and sleek look.IBC panels can be easily customised to fit a wide range of shapes and sizes, giving users peace of mind that their solar energy choices won’t compromise the visual integrity of their structure.

4. IBC solar panels are used in a wider range of applications

IBC technology seamlessly combines aesthetics and performance. Unlike PERC panels, IBC panels have no frontal metal contacts, resulting in an elegant and smooth appearance. Users can confidently choose to go solar without compromising the aesthetic integrity of their project, making them particularly suitable for PV building integration scenarios.

Comparison of IBC Technology and TOPCon Technology

Both IBC and TOPCon technologies are innovative developments in the solar industry that are improving the efficiency and performance of solar panels. However, they have unique characteristics and considerations.

1. IBC solar panels are more efficient at generating electricity:

IBC panels are sometimes more efficient than TOPCon panels, as data shows that IBC has a theoretical conversion efficiency limit of 29.1 per cent, which is higher than TOPCon’s 28.7 per cent. Both technologies have excellent efficiencies.

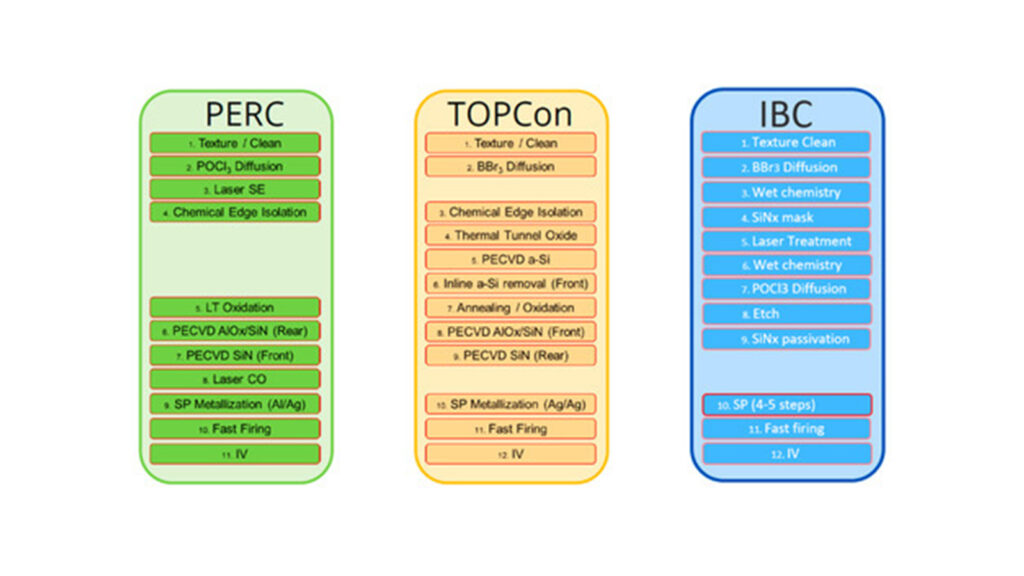

2. Manufacturing Complexity:

Since TOPCon technology is an upgrade of PERC technology, it does not add much to the final cost of the product; however, as a manufacturer with 15 years of solar panel production strength, MaysunSolar is able to offer competitive pricing for IBC panels, which further enhances the market competitiveness of IBC solar panels.

3. IBC solar cell technology is more commercially viable:

Currently, both technologies are now dependent on a number of factors, including manufacturing costs, scalability and consumer demand, to be commercially viable. However, the single-sided structure of IBCs allows IBC technology to be combined with TOPCon, HJT, Calcium Titanite and other cell technologies to create TBC, HBC and PSC IBC technologies, all of which have higher conversion efficiencies.

4. IBC solar panels are more durable and reliable:

Unlike TOPCon solar panels, IBC solar panels exhibit higher durability, with IBC cells degrading by 1.5% in the first year and an average of 0.4% per year thereafter, compared to TOPCon solar panels over a 25-year warranty period.

As a pioneer in renewable energy, Mayun Solar has launched its latest breakthrough range of IBCs in a wide range of colours, including all black, black frame and silver frame, with power ranging from 410W-600W. The modules are cleverly designed and have a conversion efficiency of up to 22.8%, which makes them an ideal choice for both residential rooftops and large commercial enterprises!Click on the picture for more product details.

The final decision between IBC solar cell technology, PERC technology, and TOPCon technology will depend on the needs of individual solar projects, available funding, and the expected course of innovation in solar panel manufacturing over the next few years.

Since 2008, Maysun Solar has been specialising in the production of high quality photovoltaic modules. We have a wide selection of solar panels in Half-Cut, MBB, IBC, TOPCon, and Shingled technologies that offer superior performance and sleek designs that will blend seamlessly into any building. Whichever technology you choose, Maysun Solar has the option for you!

Below is a photo of our German customer covering their roof with Maysun Solar’s solar panels! Click on the picture for more product information!

Maysun Solar has successfully established offices, warehouses, and long term relationships with excellent installers in many countries! For the latest module quotes or any PV related enquiry, please feel free to contact us.

New Photovoltaic news you should know about (March 2024)

Table of Contents REC Unveils a 430 W Heterojunction Solar Module Boasting 22.2% Efficiency REC, a Singapore-based PV module manufacturer, introduces its residential solar modules featuring Alpha heterojunction cell technology. Production has commenced at REC’s Industry 4.0 fab in Singapore, with initial shipments

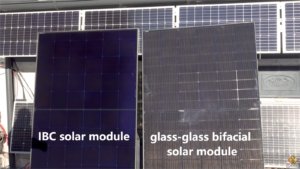

IBC Solar Modules vs. Bifacial Glass-Glass Solar Modules: Which Is More Suitable for Winter or Low-Light Conditions?

Table of Contents Introduction As the demand for renewable energy continues to surge, advancements in solar technology have broadened the spectrum of component choices available to us. Among these, IBC (Interdigitated Back Contact) full black solar modules have garnered special attention due to

Why Are Lightweight Bifacial Solar Panels the Best Choice for Balcony Solar Power Plants?

Table of Contents In the quest for efficient and eco-friendly home energy solutions, solar photovoltaic technology has emerged as a key player due to its sustainability and clean energy benefits. Particularly in the space-constrained urban settings, the effective conversion of every inch of

Questions You Might Ask About Balcony Solar Power Plants in 2024

Table of Contents What is a Balcony Solar Power Plant? Similar to a traditional photovoltaic panel, a Balcony Solar Power Plant is a device designed to generate electricity from solar energy. This green energy generator is specifically tailored for self-consumption, but it comes with

A Step-by-Step DTU Guide for Balcony Solar Power Plants

As renewable energy becomes increasingly integral in our daily lives, Maysun Solar’s Balcony Solar Power Station, with its advanced technology and user-friendly design, represents a transformative approach to home solar solutions. The integration of a Data Transfer Unit (DTU) enhances its smart functionality

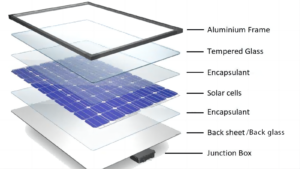

What Are The Main Components of Solar Panels?

What are the main components of solar panel? Solar panels, the cornerstone of solar energy technology, are composed of several integral parts, each contributing to their ability to harness sunlight and convert it into electrical energy. In this article, we will explore the essential