What are the main components of solar panel?

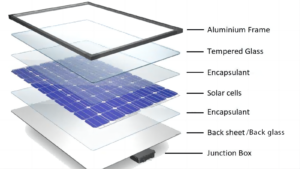

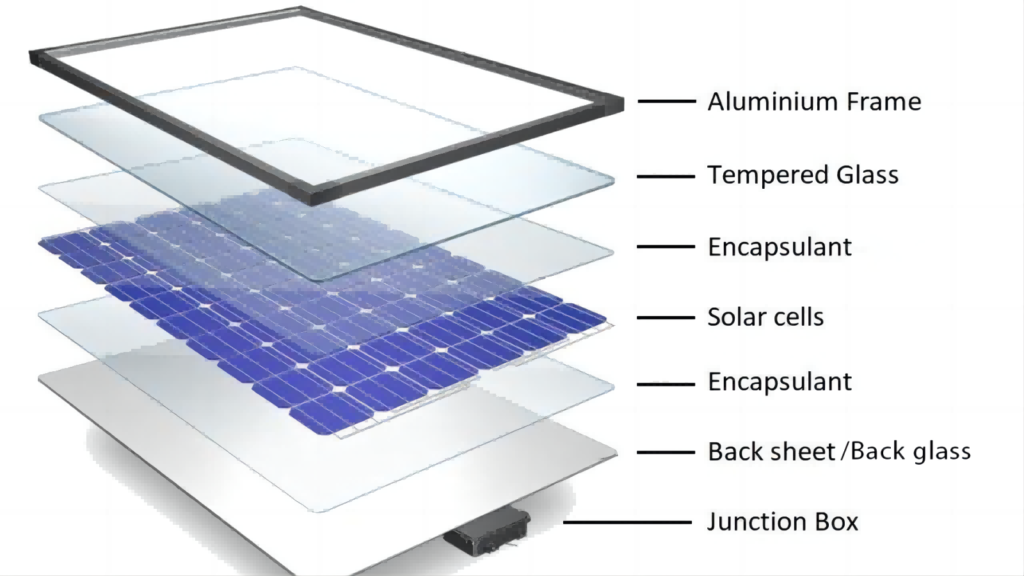

Solar panels, the cornerstone of solar energy technology, are composed of several integral parts, each contributing to their ability to harness sunlight and convert it into electrical energy. In this article, we will explore the essential components that make up a solar panel, examining how each part plays a critical role in the panel’s operation and efficiency. From the protective glass on the surface to the vital junction box for electrical connections, every component is crucial for the solar panel’s performance. Let’s delve into the world of solar panels and uncover the intricacies of their construction!

Table of Contents

Solar Panel Glass

Within solar panels, photovoltaic glass plays a pivotal role. It serves as a vital shield, safeguarding solar cells and soldering ribbons from harsh environmental elements like impacts, hail, moisture, salt mist, and ammonia. Moreover, it has a dual role in collecting, transmitting, and reducing light reflection, all of which maximize the generation of electricity.

the key attributes and applications of photovoltaic glass are as follows:

Outstanding Light Transmission: Photovoltaic glass boasts exceptional light transmittance. Regular tempered glass lets through approximately 91.5% of light, while specially treated glass (e.g., coated glass) can achieve around 93.5% transmittance. This means more sunlight can directly reach the solar cells through the glass, increasing the overall energy conversion efficiency of the solar panel.

Wide Spectrum Capture: This glass effectively captures light within the spectrum ranging from 380 to 1100 nanometers, harnessing the primary energy bands of sunlight. Additionally, it reflects infrared rays (wavelengths exceeding 1200 nanometers), reducing heat absorption and preventing high temperatures from compromising panel efficiency.

Robust Impact Resistance: Photovoltaic glass exhibits robust impact resistance. For instance, 3.2mm fully tempered glass can endure a 1kg steel ball dropped from 1 meter and hailstones up to 2.5mm in diameter, ensuring the safety and stability of solar panels even in severe weather conditions.

Glass Types and Thicknesses for Different Solar Panels:

Mono-Glass Solar Panels: Typically employ 3.2mm fully tempered glass, with a backsheet used on the rear.

Dual-Glass Solar Panels: Generally utilize 2.0mm or 1.6mm semi-tempered glass for both front and back sides. Semi-tempered glass falls between standard flat glass and fully tempered glass in terms of impact resistance and temperature tolerance. Its flatness and minimal stress make it beneficial for the production process of dual-glass solar panels, enhancing yield and quality.

Solar Panel Encapsulation Film

Encapsulation films, also known as solar panel encapsulants, are essential components in solar panels. Positioned between the front glass and the rear backsheet of the solar panel, they play a critical role in securing and protecting the solar cells, while also providing necessary insulation and waterproofing.

Key functions and features of encapsulation films include:

Protection of Solar Cells: Encapsulation films stabilize solar cells, preventing movement or breakage, thus ensuring the structural stability and long-term operational efficiency of the panel.

Transparency and Weather Resistance: High-quality encapsulation films possess excellent transparency, minimizing loss of solar energy. They are also required to be weather-resistant, withstanding the impacts of UV rays, high temperatures, and other harsh environmental conditions.

Insulation and Waterproofing: These films provide insulation for the panel, preventing moisture and other environmental elements from penetrating, thus protecting the solar cells from corrosion and damage.

Durability: The material of the encapsulation film must be capable of enduring prolonged exposure to sunlight and various climatic changes, maintaining its performance over time.

Common types of encapsulation films include EVA (Ethylene-Vinyl Acetate), POE (Polyolefin Elastomer), and co-extruded EPE.

EVA Film: Typically used for encapsulating mono-crystalline P-type Perc modules. Made from ethylene-vinyl acetate copolymer, with the main component being acetic acid ethenyl ester (40-70%). Advantages include low cost, ease of processing, rapid cross-linking, and a simple, stable, and mature application. However, EVA is prone to hydrolysis in light, oxygen, and humid-heat environments, leading to acetic acid production that can corrode solar cells and solder ribbons. It also reacts with sodium in glass, forming a large amount of mobile sodium ions, causing power attenuation; EVA tends to yellow under photothermal conditions, affecting transparency and resulting in power loss of the module.

POE Film: Used for encapsulating dual-glass and N-type photovoltaic modules. POE, a type of polyethylene, has superior properties compared to EVA, such as low water permeability, hydrolysis resistance, high-temperature and humidity resistance, aging resistance, excellent PID resistance, high electrical resistivity, and superior water vapor barrier properties. However, it has higher processing complexity and cost than EVA.

EPE Film: A composite of EVA+POE+EVA. It combines the ease of processing of EVA with the excellent PID and water vapor resistance of POE. Suitable for N-type Topcon solar cells and dual-glass modules, EPE offers a balanced cost-performance ratio.

Solar Cell

Solar cells are what turn sunlight into power. They are the heart of solar panels. The efficiency and features of these cells rely on the kind of semiconductor material that is used.

There are two main types: P-type and N-type.

P-type solar cells:

Made by adding trivalent elements (like boron) to basic semiconductor materials like silicon, which creates positively charged “holes” (areas that don’t have any electrons).

When these “holes” are hit by an electric field, they become the main charge carriers and create an electric current.

P-type materials are commonly used in multicrystalline silicon solar cells and some monocrystalline silicon solar cells because they are cheap and easy to make.

N-type solar cells:

Doping silicon with pentavalent elements, like phosphorus, adds more valence electrons to the material, making it better at conducting electricity.

When there is an electric field, these extra electrons move as the main charge carriers, which makes an electric current.

Because they are stable over time and work well, N-type materials are becoming more and more important in TOPCon, IBC, and HJT, which are high-efficiency solar cell technologies.

Most common types of solar cells on the market:

Technology is moving quickly forward in the solar cell business. Particularly N-type materials have gotten a lot of attention lately because they work so well. For example, HJT (Heterojunction) solar cells combine the best features of crystalline and amorphous silicon. They make the cells more stable and efficient by putting an amorphous silicon layer between N-type and P-type silicon. This stops electrons and holes from recombining. Tunnel oxide layers and polycrystalline silicon layers are used as electrodes in TOPCon technology, which makes the cell work better overall. IBC (Interdigitated Back Contact) cells also absorb more light and lessen shading effects because all of their electrodes are on the back of the cell.

N-type solar cells will likely play a bigger role in the future solar energy market as technology improves and costs go down. P-type cells, on the other hand, will continue to be widely used because they have a stable market position and well-developed production processes. These improvements not only make solar cells more efficient at converting light into electricity, but they also lay the groundwork for more sustainable and eco-friendly energy options.

Solar Panel Backsheet / Back Glass

The backsheet of the module is mainly used in outdoor environment to protect the solar cell module to resist the erosion of light, humidity, heat, freezing and other environmental influences on the encapsulation film, cell and other materials, and to play the role of weather-resistant insulation protection, the quality of the backsheet determines the life of the module.

Backsheets:

Backsheets serve as critical components of solar panels, playing a pivotal role in safeguarding them against environmental factors such as light, moisture, heat, and cold. This protective layer is indispensable for prolonging the lifespan of solar panels while shielding their internal components from potential harm.

Here’s a closer look at backsheets:

Variety in Appearance: Backsheets come in various colors, including white, black, and transparent. White backsheets are designed to reflect sunlight back onto the solar cells, thereby improving energy efficiency. Black backsheets, favored in Europe and America, enhance the aesthetic appeal of rooftop installations. Transparent backsheets enable solar panels to generate electricity from both sides.

Material Composition: Typically, backsheets consist of three layers: an outer coating, a middle PET substrate, and an inner coating. To ensure durability and protection against UV radiation, different materials, such as fluorine and PVDF films, are commonly used in these layers.

Performance Compatibility: Backsheets are engineered to be compatible with different types of solar cells, including Perc, N-type, and TOPCon cells. Their low water permeability is crucial for maintaining cell efficiency and longevity, ensuring that solar panels operate efficiently for an extended period.

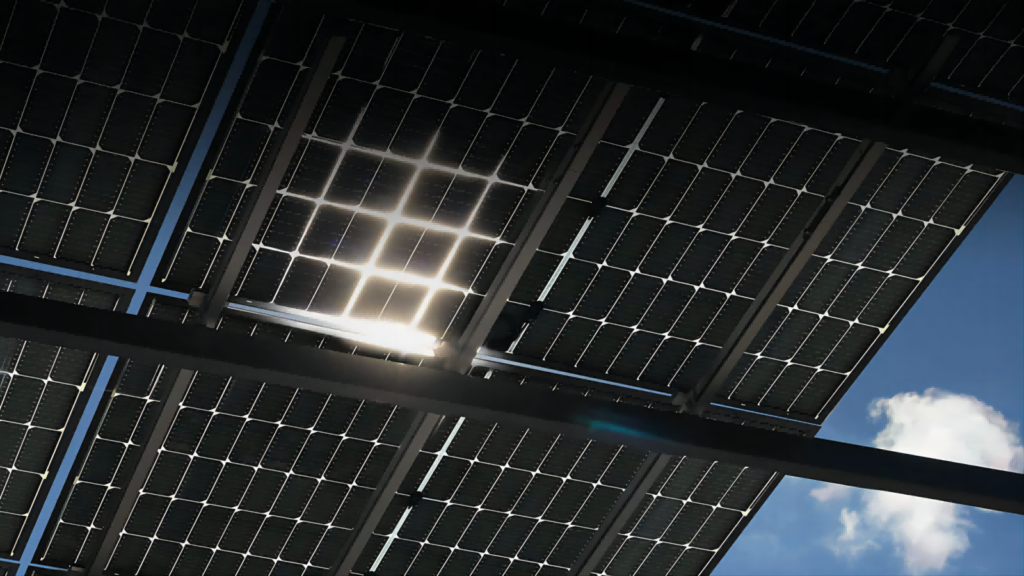

Back Glass:

Back glass comes in two thicknesses, 2.0mm and 1.6mm, and is gaining popularity due to its exceptional durability and resilience against environmental conditions.

Here are some advantages and applications of back glass:

Moisture Barrier: Back glass boasts nearly zero moisture permeability, making it ideal for high-humidity environments, where it effectively prevents water-induced damage.

Resilience and Longevity: Its high resistance to wear, weathering, and corrosion makes it suitable for use in extreme conditions, ultimately extending the lifespan of solar panels.

Fire Safety: Solar panels equipped with rear glass exhibit high fire resistance, making them a safer choice for residential and industrial installations.

Insulation Properties: The excellent insulation properties of rear glass enable solar panels to handle higher system voltages, potentially offering cost-effective solutions for large solar power stations.

Incorporating back glass into solar panel design enhances their durability, safety, and performance, making them reliable and efficient contributors to clean energy generation. Read the article below to learn more details about solar panel backsheet!

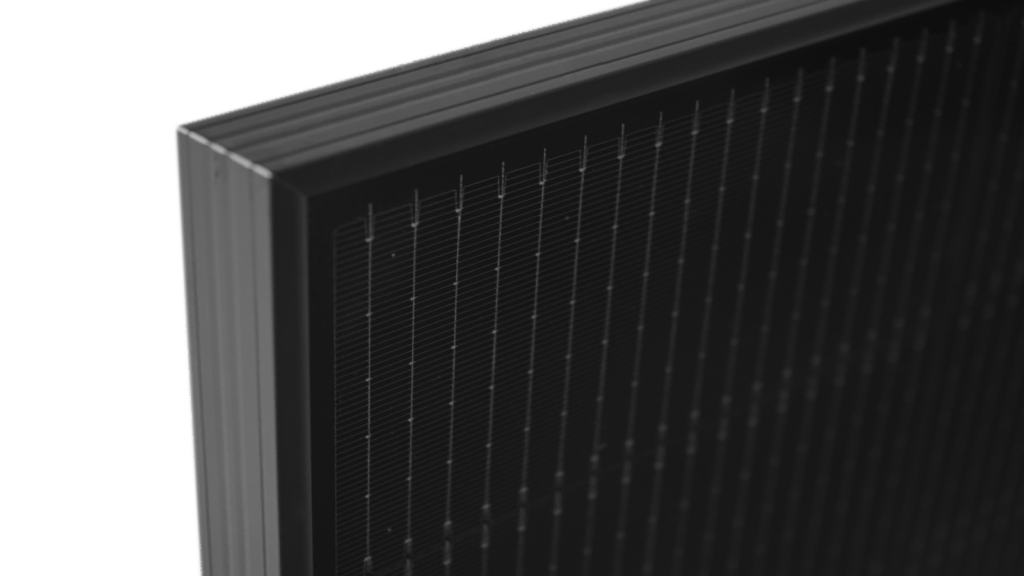

Solar Panel Frame

Since aluminum is the most abundant metal on earth, it is used as the frame, usually made of aluminum alloy. It also plays a big role in solar panels.

Structural Support: The bezel provides structural support for the solar panel, increasing the overall strength and stiffness of the panel. This helps prevent the panel from bending or twisting during installation and transportation, keeping the panel flat and stable.

Edge Protection: The bezel protects the edges of the panel from physical damage such as bumps, shocks or crushing. It reduces wear and tear on the edges of the panels and extends the life of the panels.

Reduces Contamination and Moisture Intrusion: The presence of a bezel reduces the amount of dirt, dust and moisture that can enter the underside of the panel, helping to maintain the cleanliness and performance of the panel.

Simplifies Installation: Borders often feature pre-mounted holes and clamps that make solar panel installation easier. Installers can easily attach the panels to a rack or roof without having to deal directly with the panel’s surface, reducing the risk of potential damage.

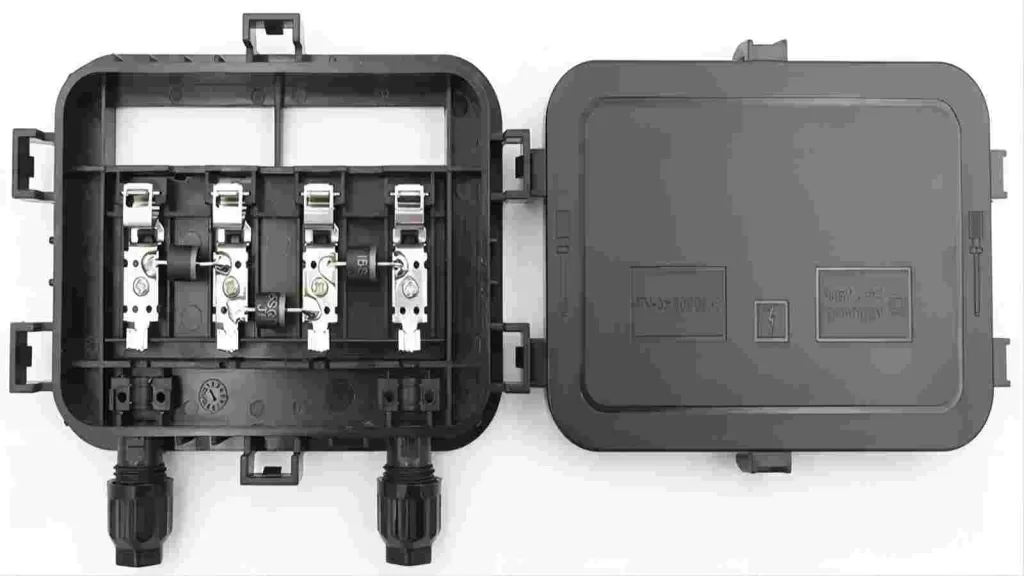

Solar Panel Junction Box(J-Box)

A Junction Box (J-Box) is a crucial component in solar panels, primarily serving as a connector between the solar panels and the external circuitry. Its primary role is to act as a transfer station for the electrical energy generated by the solar panels to be transmitted to external circuits or storage systems.

Key features of a Junction Box include:

Energy Transmission: Inside the junction box are conductive connection points and busbars that collect the current generated by the solar panels and transfer it through cables to the external circuitry or battery storage systems.

Protective Function: Junction boxes are typically well-sealed, preventing water, dust, and other external substances from entering and protecting the internal circuitry of the panels. They also provide a degree of resistance against mechanical impacts and environmental erosion.

Diode Protection: To prevent reverse current flow and avoid hot spot effects, junction boxes usually contain diodes. These diodes provide a bypass path in cases where the solar panels are partially shaded or underperforming, ensuring stable operation and efficiency.

Water and Dust Resistance: Junction boxes are designed to meet specific water and dust resistance standards, such as IP65, IP67, or IP68, to ensure stable operation under various environmental conditions.

Smart Features: Modern junction boxes may also come with smart features like remote monitoring, intelligent shutdown, and power optimization (MPPT). These features help to enhance the overall efficiency and safety of solar power stations.

The goal of Maysun Solar since 2008 has been to make the best solar panels. Check out our wide range of half-cut, MBB, IBC, HJT, and shingled solar panels, which come in silver, full black, black frame, and glass-glass styles. Beautiful designs and great efficiency make the panels stand out and make any building look better. Maysun Solar is a reliable choice because it has long-standing offices and warehouses and relationships with top installers in many countries. Feel free to get in touch with us if you have any questions about solar panlels or want the most up-to-date quotes on solar panels. We’re happy to help.

New Photovoltaic news you should know about (March 2024)

Table of Contents REC Unveils a 430 W Heterojunction Solar Module Boasting 22.2% Efficiency REC, a Singapore-based PV module manufacturer, introduces its residential solar modules featuring Alpha heterojunction cell technology. Production has commenced at REC’s Industry 4.0 fab in Singapore, with initial shipments

IBC Solar Modules vs. Bifacial Glass-Glass Solar Modules: Which Is More Suitable for Winter or Low-Light Conditions?

Table of Contents Introduction As the demand for renewable energy continues to surge, advancements in solar technology have broadened the spectrum of component choices available to us. Among these, IBC (Interdigitated Back Contact) full black solar modules have garnered special attention due to

Why Are Lightweight Bifacial Solar Panels the Best Choice for Balcony Solar Power Plants?

Table of Contents In the quest for efficient and eco-friendly home energy solutions, solar photovoltaic technology has emerged as a key player due to its sustainability and clean energy benefits. Particularly in the space-constrained urban settings, the effective conversion of every inch of

Questions You Might Ask About Balcony Solar Power Plants in 2024

Table of Contents What is a Balcony Solar Power Plant? Similar to a traditional photovoltaic panel, a Balcony Solar Power Plant is a device designed to generate electricity from solar energy. This green energy generator is specifically tailored for self-consumption, but it comes with

A Step-by-Step DTU Guide for Balcony Solar Power Plants

As renewable energy becomes increasingly integral in our daily lives, Maysun Solar’s Balcony Solar Power Station, with its advanced technology and user-friendly design, represents a transformative approach to home solar solutions. The integration of a Data Transfer Unit (DTU) enhances its smart functionality

What Are The Main Components of Solar Panels?

What are the main components of solar panel? Solar panels, the cornerstone of solar energy technology, are composed of several integral parts, each contributing to their ability to harness sunlight and convert it into electrical energy. In this article, we will explore the essential

The information was useful, thank you very much