Component failure

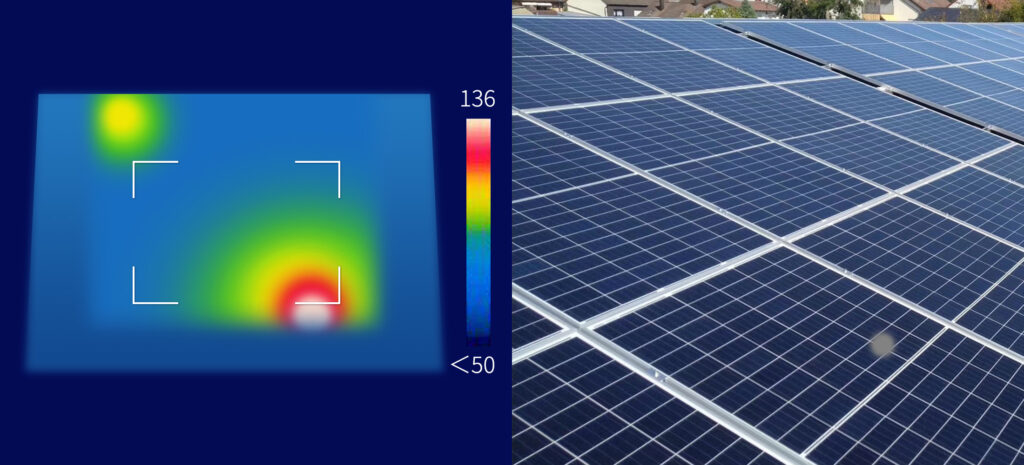

1. Hot spot effect

This refers to a certain condition, in the power generation state of the photovoltaic module series branch circuit is blocked or defective area is used as a load, consumption of other light area generated energy, resulting in local overheating, this phenomenon is known as the photovoltaic module “hot spot effect”

Solution:

Minimize glass bending when handling modules

regularly check the surface of the module for foreign objects

Regularly check the bypass diode and temperature test in the solar panel junction box

keep the surface of the solar module clean

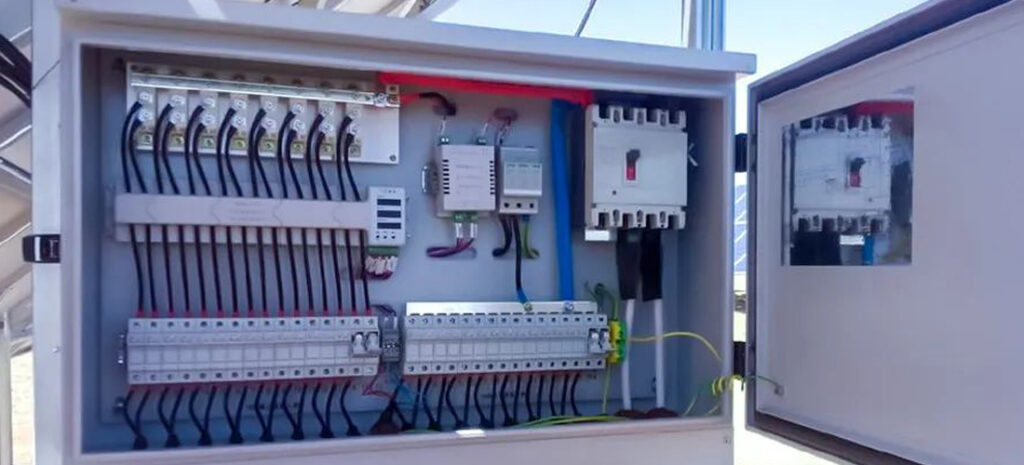

2. Solar module junction box failure

Solar modules in operation, junction box diode breakdown heat burn loss, convergence with open weld burn and serious cases the entire junction box burn, no power output

Solution:

suggest the junction box reserved for expansion connection seat

installation of different specifications of the diode, you can always change the maximum working current of the junction box

recommended in the junction box box cover set up air valve, used to export the internal heat of the junction box, or increase the heat sink

regularly check the operating condition of the junction box and temperature test

Inverter failure

1. Inverter screen does not display

Analysis of the fault, there is no DC input, the inverter LCD is DC powered, it may be that the DC switch is not closed, or a component has a short circuit.

Solution:

Use a multimeter voltage file to measure the inverter DC input voltage. When the voltage is normal, the total voltage is the sum of the voltage of each group. If there is no voltage, you need to test the DC switch, terminals, cable connectors and components in turn to see if they are normal. If it is a multiplex component, it should be separately accessed and tested separately.

If the inverter is used for a period of time and no reason is found, the inverter hardware circuit is malfunctioning, please contact the company after-sale.

2. Inverter hardware failure

Inverter circuit board, detection circuit, power circuit, communication circuit and other circuits are faulty, or fan or blower is faulty.

Solution:

If the above hardware failure occurs in the inverter, please disconnect all the DC and AC terminals and let the inverter power down for more than 30 minutes. If you can recover it by yourself, continue to use it, if not, contact the after-sales technical engineer. Normally, you need to clean the inverter regularly and strengthen the inverter operation monitoring.

System output power does not reach the ideal power

There are many factors affecting the output power of PV power plant, including the amount of solar radiation, the tilt angle of solar cell modules, dust and shadow blocking, and the temperature characteristics of the modules.

The common solutions for low system power due to improper system configuration and installation are:

Before installation, test each module for sufficient power.

Adjust the mounting angle and orientation of the modules.

Check the components for shadows and dust.

Check if the voltage is within the voltage range after the components are connected in series, too low voltage will reduce the system efficiency.

Before installing multi-way string, check the open circuit voltage of each string, the difference is not more than 5V, if you find the voltage is not right, check the line and connectors.

installation can be accessed in batches, each group of access to record the power of each group, the power difference between the strings does not exceed 2%.

The installation place is not well ventilated, and the inverter heat is not spread out in time, or exposed to the sun directly, causing the inverter temperature to be too high.

inverter has double MPPT access, each way input power is only 50% of the total power, in principle, each way design installation power should be equal, if only connected to one way MPPT terminal output power will be cut in half.

cable joints poor contact, cable is too long wire diameter is too thin have voltage loss finally caused by power loss.

PV plant grid-connected AC switch capacity is too small to meet the inverter output requirements.

Maysun Solar, as a PV module manufacturer with 15 years of professional experience, can provide you with high quality solar panels, click the button below to contact us and get a product quote.

You may also like:

Latest Solar Industry News (May 2024)

Table of Contents Italy Bans PV Installations on Agricultural Land The Italian government has introduced a decree prohibiting the establishment of large-scale solar plants on productive agricultural land to prevent desertification. Minister of Agriculture Francesco Lollobrigida stressed the need for photovoltaic systems to

TOPCon Solar Panel, The wise Choice for Cost-Effectiveness

Table of Contents Introduction In today’s world, we are in a crucial period of transition from traditional energy sources to clean energy. Solar energy, as one of the most promising clean energy sources, has garnered global attention and investment. However, with the continuous

Can Photovoltaic Power Generation Lead to Photovoltaic Fires? Prevention and Response Strategies

Table of Contents Introduction Although photovoltaic power generation is a clean, safe and environmentally friendly way of generating electricity, which has risen rapidly and been widely used in recent years, just like all electrical equipment, photovoltaic power stations also have certain fire hazards.

New Photovoltaic news you should know about (March 2024)

Table of Contents REC Unveils a 430 W Heterojunction Solar Module Boasting 22.2% Efficiency REC, a Singapore-based PV module manufacturer, introduces its residential solar modules featuring Alpha heterojunction cell technology. Production has commenced at REC’s Industry 4.0 fab in Singapore, with initial shipments

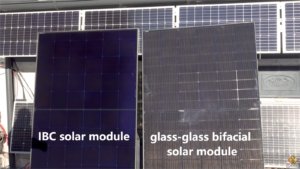

IBC Solar Modules vs. Bifacial Glass-Glass Solar Modules: Which Is More Suitable for Winter or Low-Light Conditions?

Table of Contents Introduction As the demand for renewable energy continues to surge, advancements in solar technology have broadened the spectrum of component choices available to us. Among these, IBC (Interdigitated Back Contact) full black solar modules have garnered special attention due to

Why Are Lightweight Bifacial Solar Panels the Best Choice for Balcony Solar Power Plants?

Table of Contents In the quest for efficient and eco-friendly home energy solutions, solar photovoltaic technology has emerged as a key player due to its sustainability and clean energy benefits. Particularly in the space-constrained urban settings, the effective conversion of every inch of