Solar Cells: Size

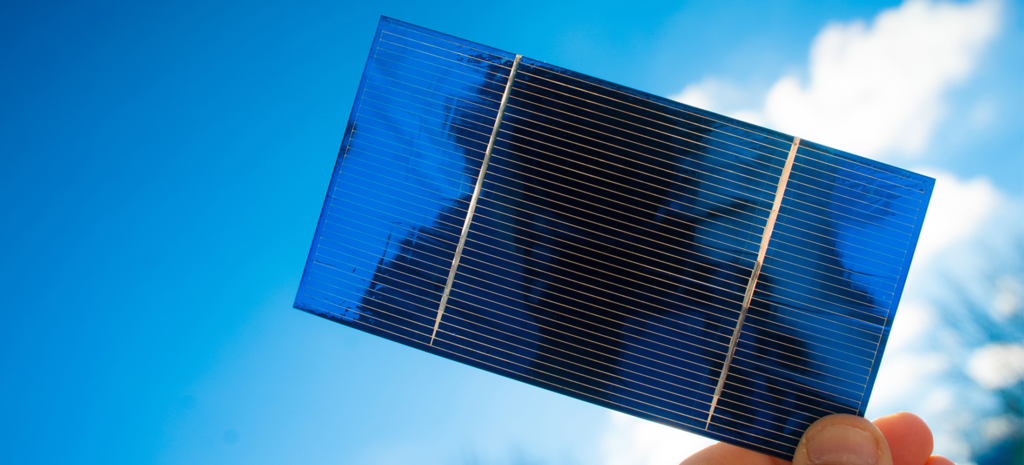

The core of photovoltaic solar panels solar cells, divided into monocrystalline solar cells and polycrystalline solar cells, because of efficiency bottlenecks, polycrystalline solar cells market share is becoming less and less, the current monocrystalline solar cells for the mainstream of the market.

1. Monocrystalline cells large size has become the mainstream of the market, before 2018 125mm 156.75mm phased out, now basically extinct, the current mainstream size to 158.75mm (G1) 166mm (M6) 182mm (M10) 210mm (G12) mainly.

2. Solar cells according to the printing screen grinding has 5bb 6bb 9bb 10bb 11bb 12bb 13bb. version of the general half cells screen pattern, 210mm (G2) 2 minutes and a half and 3 minutes film co-exist.

Solar cell size future trend: by photovoltaic solar energy authority market forecast 158.75mm (G1) 166mm (M6) with the progress of time and technology, will be phased out, the future to 182mm (M8) 210mm (G2) as the mainstream.

Solar cells: production process

The mainstream solar cell production process currently has Perc N Topcon N HIT, Perc thickness 170-180um process mainstream efficiency 22.8%, corresponding to 158.75mm 5.7W/pcs 166mm 6.2W/pcs 182mm 7.5W/pcs 210mm 10.1W/pcs.

N Topcon and N HIT thickness 120-160um process mainstream efficiency of 23.8%, corresponding to 158.75mm 6.0W/pcs 166mm 6.55W/pcs 182mm 7.85W/pcs 210mm 10.5W/pcs

Solar Cell: Technology Analysis.

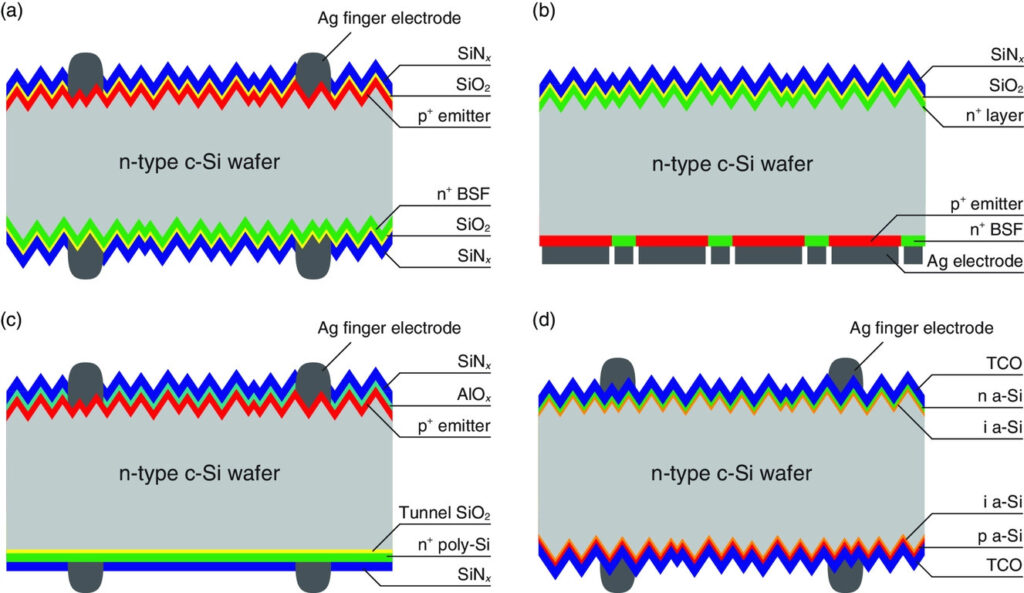

N-type PERT solar cell technology.

Full diffusion backfield passivation structure solar cell, usually P-N junction on the front side, with full diffusion backfield on the back side

The simplest structure, the earliest application of N-type solar cells

Double-sided structure, 80-95% bifacial rate, silver-aluminium grid wire on front side, silver-aluminium grid wire on back side

No competitive advantage over PERC in terms of mass production efficiency and cost

N-Type TOPCON solar cells.

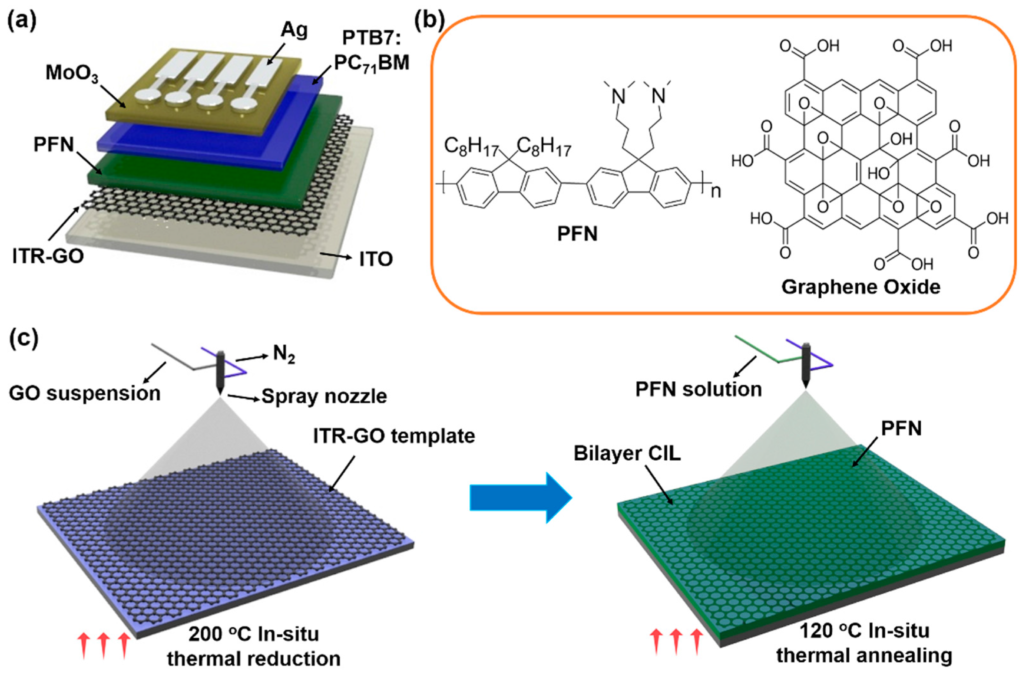

TOPCON (Tunnelling Oxide Passivation Contact) solar cells

Where a very thin layer of silicon oxide is deposited on the back of an N-type wafer, followed by a layer of heavily doped polycrystalline silicon film to achieve a tunnelling passivation on the back side to increase the open circuit voltage

Current mass-produced solar cell efficiency of over 24%, with a slightly lower bifacial rate relative to PERT

PERC production line can be upgraded to TOPCON in the future

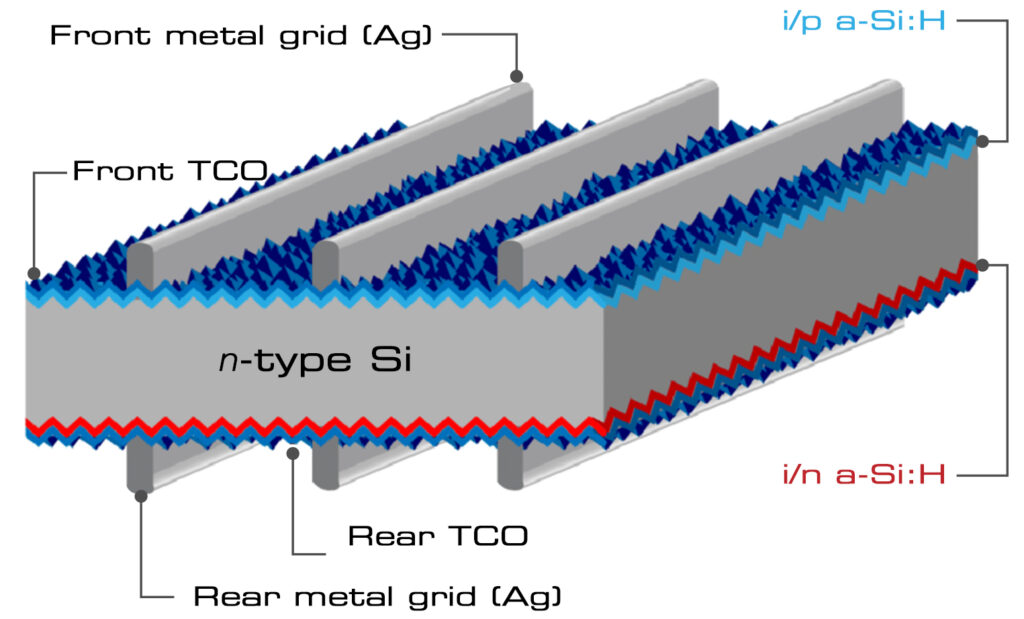

Heterojunction solar cells

Heterojunction on N-type silicon substrate with amorphous silicon as a passivation layer; heterojunction allows higher open-circuit voltages with an additional transparent conductive layer.

Requires low temperature silver paste, 200°C, and allows for thinner N-type wafers to reduce costs.

Mass production solar cell efficiency of about 24%, high open voltage makes the power temperature coefficient value low, about 0.28%/°C, double-sided rate of more than 90%.

High cost of equipment and materials, high engineering difficulty

N HJT Advantages Simple manufacturing process, highest power conversion rate Huge potential for efficiency improvement, process suitable for thin wafer (100-160um) production Significant reduction in silicon based material costs, basically no power degradation High bifacial rate. Disadvantages are large initial equipment investment and technical difficulties But as technology advances and equipment development progresses, costs will be equal to and lower than the Perc process, with huge market development potential.

N-type IBC solar cells.

Differential finger-like back-contact solar cells with no grid line shading on the front side to increase current.

Can be combined with heterojunctions with amorphous silicon passivation layers or tunneling passivation layers to form HBC structured solar cells.

Complex solar cell structures lead to complex production processes and high costs.

PERC solar cell efficiency potential analysis.

Perc process is currently the mainstream of the market, the advantage is the technology is mature, low cost, the disadvantage is the efficiency conversion rate and then enhance the difficulty, power decay (made into components after the first year less than 3%, after 0.5% per year), 1 year PERC solar cell mass production efficiency is expected to increase to 23.5%.

Theoretically, PERC solar wire efficiency is expected to rise to 24%, but the technical difficulties and cost challenges of further upgrading after efficiency reaches 23.5% have increased significantly.

Solar cells: future trends in technology

The efficiency of N Topcon and heterojunction solar cells has been steadily improving recently, with advanced production lines currently capable of achieving efficiencies of over 24%.

The advantages of N Topcon are high power conversion rate, high potential for efficiency improvement, process suitable for thin wafer (100-160um) production significantly reduce the cost of silicon-based materials, basically no power decay high double-sided rate. Disadvantages are large initial investment in equipment and many technical processes High costs.

Calcium titanium ore and laminated solar cell technologies have also made major breakthroughs, and in 5-10 years, there is hope that calcium titanium ore and crystalline silicon solar cell technologies can be superimposed to achieve conversion efficiencies of over 30%.

Maysun Solar has an N-type PV module, click to learn more.