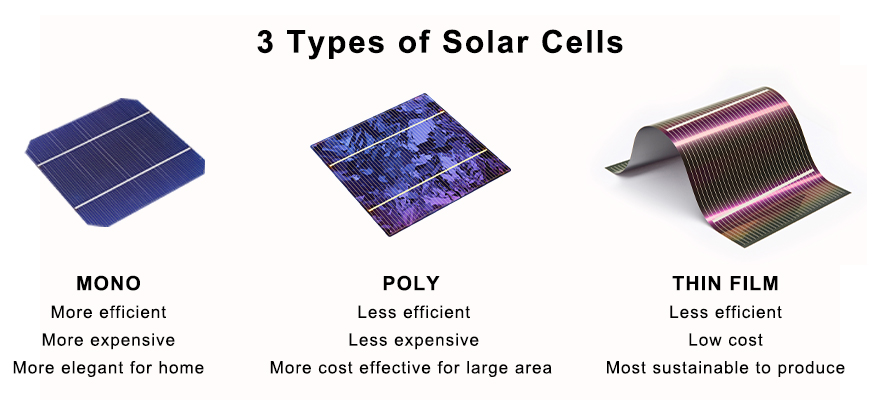

The main types of solar panels on the market today are monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells.

Differences between monocrystalline, polycrystalline and amorphous silicon solar cells:

Appearance:

The four corners of monocrystalline silicon cells show a rounded shape with no pattern on the surface.

Polycrystalline silicon cells have four corners with square corners and a pattern on the surface similar to that of an ice flower.

Amorphous silicon solar cells are also known as thin-film modules. Unlike crystalline silicon cells where the grid lines can be seen, the surface is as clear and smooth as a mirror.

Applications:

Although the average conversion efficiency of monocrystalline silicon cells is about 1% higher than that of polycrystalline silicon, because monocrystalline silicon cells can only be made quasi-square (all four sides are circular), so when forming a solar panel there will be a part of the area that is not filled; whereas polycrystalline silicon is square, so there is no such a problem.

Manufacturing process:

Polycrystalline silicon solar cells consume about 30% less energy in the manufacturing process than monocrystalline silicon solar cells, so polycrystalline silicon solar cells account for a large share of the world’s total solar cell production, and manufacturing costs are also less than monocrystalline silicon cells, so the use of polycrystalline silicon solar cells will be more energy efficient and environmentally friendly!

Advantages and disadvantages of crystalline silicon modules and amorphous silicon modules:

Crystalline silicon modules: The power of a single module is relatively high. With the same footprint, the installed capacity is higher than that of thin film modules. However, the modules are heavy and fragile, with poor high temperature performance, poor low light and high annual attenuation rate.

Thin film modules: The power of a single module is relatively low. But the power generation performance is high, the high temperature performance is good, the low light performance is good, the shadow shading power loss is small, and the annual decay rate is low. Wide range of applications, aesthetically pleasing and environmentally friendly.

Summary:

The utilisation area of monocrystalline will be higher, monocrystalline in area utilisation will be better; polycrystalline market proportion is higher, the application is more extensive, the price is also has certain advantages.

So, when we choose PV modules, we should choose crystalline silicon PV modules more mature products according to the actual situation, if you think it is too complicated, then just remember that for the same power of the PV system, the power generation is also consistent.

Of course, the choice of photovoltaic modules should be more recognized brand, not only to effectively reduce the sunlight reflectivity, while allowing the battery photoelectric conversion rate to a higher layer.

Following such confusing times, people often find themselves locked up in a dilemma on the decision of installing the appropriate PV module for their homes, offices, etc. And for that very reason, we are here ready to assist you in whatever you need. Contact us now at Whatsapp: +86 159 2091 1832 and get a quote.