Table of Contents

In the dynamic landscape of solar energy, the Interdigitated Back Contact (IBC) solar cell emerges as a beacon of innovation and efficiency. As we delve into the realm of IBC solar panels, we uncover the groundbreaking principles that make them a compelling force in the pursuit of clean and sustainable energy solutions. This article explores the technical principles, advantages, and applications of IBC solar technology, shedding light on its potential to redefine the future of solar energy.

How do IBC Cells Work?

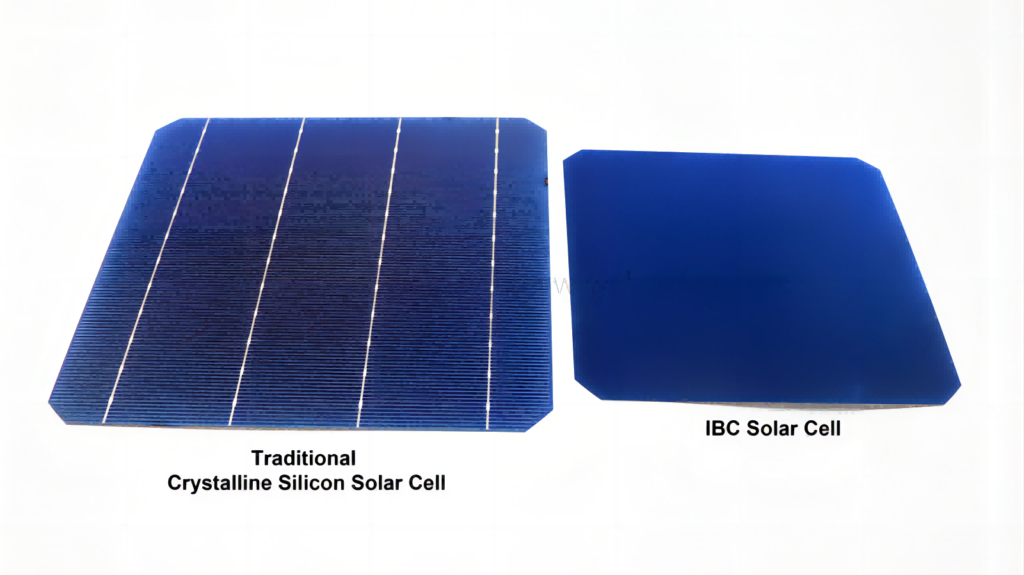

The Interdigitated Back Contact (IBC) solar cell is an advanced photovoltaic technology designed for superior efficiency and energy capture. Unlike conventional solar cells, IBC cells feature contacts on the rear side, minimizing shading and enhancing light absorption. This back contact design reduces recombination losses by strategically placing positive and negative contacts, thereby improving charge carrier collection efficiency.

IBC cells stand out for their exceptional conversion efficiencies, surpassing traditional solar cells. The unique design minimizes shading and recombination losses while optimizing light absorption, resulting in increased energy yield from the same amount of sunlight.

What are the Benefits of IBC Solar Panels?

The most advanced technology:

IBC (Interdigitated Back Contact) stands out as the cutting-edge tunneling technology employed in the large-scale manufacturing of Photovoltaic (PV) solar panels. Boasting unparalleled advantages when compared to PERC (Passivated Emitter Rear Contact) and TOPCon (Tunnel Oxide Passivated Contact), IBC represents the forefront of third-generation cell technology. This technology has reached a high level of sophistication, and IBC solar panels stand as genuinely distinctive and advanced products. IBC solar panels leverage cutting-edge Interdigitated Back Contact technology, strategically placing contacts on the rear side to minimize shading and current losses, leading to unparalleled energy conversion efficiency.

High power generation efficiency:

Compared with other solar panels, IBC solar panels can produce a higher output of electricity under similar conditions, maximizing the overall efficiency of energy generation. Absence of metal bus bars on the front side minimizes light loss and increases the light-exposed area by 2.5%, thereby establishing the distinctive high short-circuit current technical characteristics of IBC cells. With a density 5-8% higher than that of PERC and TOPCon cells, IBC solar panels exhibit superior power generation performance.

Exquisite vision:

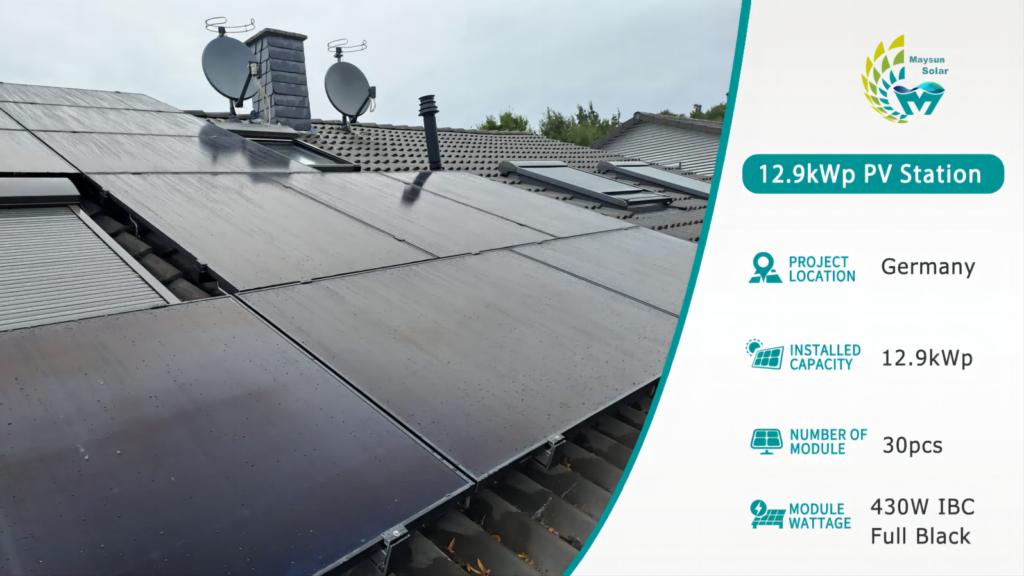

The IBC solar panels employ a distinctive rear contact technology, showcasing a refined, premium, and elegant full black design. This feature enhances their compatibility with dark-colored roofs in Europe, resulting in a more aesthetically pleasing overall appearance. In terms of visual impact, they surpass PERC and TOPCon solar panels.

Low cost:

By optimizing energy conversion efficiency, IBC solar panels demonstrate the ability to generate more electricity in a confined space, contributing to a cost-effective approach in solar energy systems. As the leading technology in the solar industry, IBC was initially associated with high costs. However, the adoption of an advanced laser patterning process has replaced the intricate photolithography process in the original IBC cell, resulting in a cost reduction. Consequently, although the price of IBC solar panels is now comparable to that of TOPCon, they are far superior to TOPCon in terms of power generation and quality, thus enhancing the strong competitiveness of IBC solar panels in the market.

Extra-long 25 year warranty:

The thoughtful design of IBC technology, reducing thermal losses and mechanical stress, often accompanies an extended warranty period, underscoring the commitment to longevity and reliability. Utilizing advanced and dependable IBC cell technology, the encapsulation material is meticulously chosen for its high UV resistance, aging resistance, and low water permeability. The TPE backsheet is layered with a PVF (Tedlar) film and an EPE modified adhesive film, undergoing rigorous double-95 tests to guarantee a 25-year warranty.

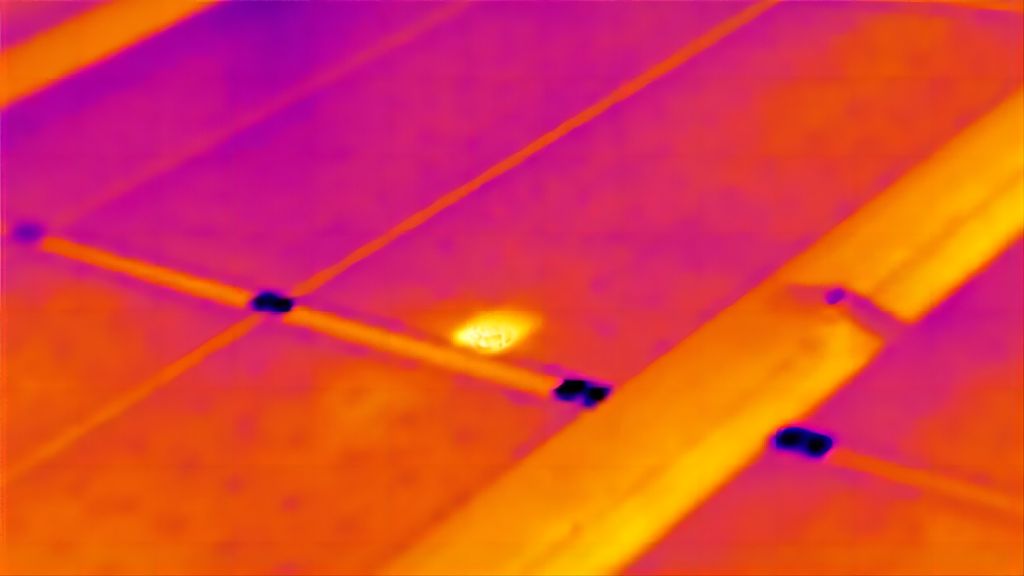

No hot spots:

IBC solar panels mitigate the occurrence of hot spots on the panel surface, enhancing overall system safety. Employing the distinctive All Back Contact technology ensures that the positive and negative metal electrodes on the back maintain normal flow even when solar panels are shaded. This eliminates resistance on the front side, consequently reducing the occurrence of hot spots on the solar panel and mitigating the risk associated with power plant operation.

Higher weather resistance:

IBC solar panels exhibit robust resistance to adverse weather conditions, showcasing stability and reliability in challenging environmental scenarios. The advanced design of All Back Contact prevents tensile damage and detachment resulting from thermal expansion and contraction of the front welding strip when the solar panel is subjected to significant temperature stress. This design ensures the reliable and stable power generation of the solar panel.

No glare light pollution:

The intentional design of IBC solar panels minimizes reflection-related issues, resulting in reduced glare and light pollution in the surrounding environment. The front side of the solar panel undergoes flawless processing without a PV ribbon, eliminating any reflection from the silver PV ribbon. The solar panel’s average reflectivity is a mere 1.7%, significantly minimizing its impact on the environment and reducing light pollution for neighboring areas.

What are the Application Scenarios for IBC Solar Panels?

Interdigitated Back Contact (IBC) solar panels have versatile applications and are suitable for various scenarios. Here are some common application scenarios for IBC solar panels:

Residential Rooftops:

IBC solar panels are often used in residential settings due to their high efficiency and aesthetic design. The absence of metal busbars on the front surface enhances the visual appeal, making them suitable for homes.

Maysun Solar’s newest IBC solar panels perfectly combine the advantages of the aforementioned IBC solar cells with high efficiency, aesthetics, and a long lifespan. Opting for Maysun Solar’s IBC solar panels can prove to be a wise choice for individuals seeking to optimize efficiency and performance. Pictured below is 430W IBC full black solar panels installed by Maysun’s German installer for a customer. If you would like more information, please click the button below!

Commercial Buildings:

Many commercial buildings and offices opt for IBC solar panels to harness solar energy cost-effectively. The high efficiency and reliable performance make them a viable choice for businesses aiming to reduce energy costs.

Industrial Installations:

IBC solar panels find applications in industrial settings, providing a sustainable and efficient energy source for large-scale operations. Their high power generation efficiency is beneficial for meeting the energy demands of industrial facilities.

Ground-Mounted Solar Farms:

IBC solar panels are suitable for large-scale ground-mounted solar farms. Their advanced technology and high efficiency contribute to maximizing energy output in utility-scale installations.

Why are IBC Solar Panels a Better Choice Compared to PERC and TOPCon?

When comparing IBC (Interdigitated Back Contact) solar panels with PERC (Passivated Emitter Rear Contact) and TOPCon (Tunnel Oxide Passivated Contact) solar panels, noticeable differences can be observed in terms of power generation efficiency, aesthetics, low-light performance, temperature coefficient, and hotspot effects. The detailed comparison is as follows:

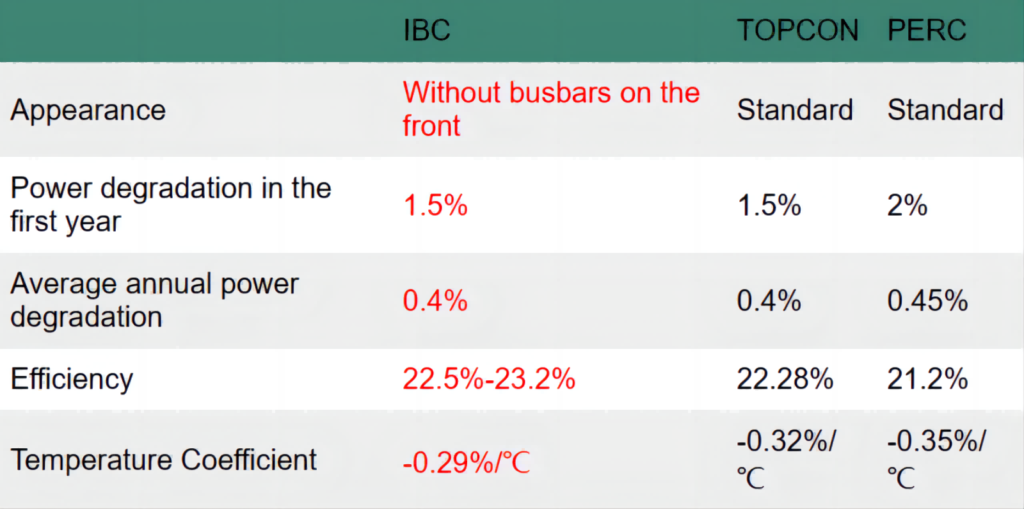

When comparing solar panels from the perspectives of Appearance, Power Degradation in the First Year, Average Annual Power Degradation, Efficiency, and Temperature Coefficient, it’s evident that IBC, TOPCon, and PERC exhibit distinctive characteristics.

Appearance

These solar panels differ in appearance. IBC panels feature a unique design without busbars on the front surface, providing a sleek and unobstructed aesthetic. In contrast, TOPCon and PERC adhere to standard designs with visible busbars, maintaining a more traditional look.

Power Degradation

When it comes to the crucial factor of power degradation, IBC stands out for its consistently low performance decline. In the inaugural year, IBC, TOPCon, and PERC show similar results with a moderate degradation. Both IBC and TOPCon experience a minimal 1.5% reduction, while PERC lags slightly behind at 2%. Looking beyond the first year, the advantage of IBC becomes even clearer. IBC and TOPCon maintain a commendable annual degradation rate of just 0.4%, emphasizing their resilience and long-term efficiency. In contrast, PERC exhibits a slightly higher rate at 0.45%, signaling a slightly faster decline over time. Choose IBC for enduring performance and minimal power loss over the years.

Efficiency

Efficiency is an area where these solar panels notably differ. IBC solar panels showcase the highest efficiency range, varying from 22.5% to 23.2%. In comparison, TOPCon achieves an efficiency of 22.28%, while PERC lags behind with a lower efficiency of 21.2%.

Temperature Coefficient

The temperature coefficient is another parameter where distinctions emerge. IBC panels boast a lower temperature coefficient at -0.29%/℃, indicating a more stable performance in high-temperature conditions. In contrast, TOPCon and PERC have higher coefficients at -0.32%/℃ and -0.35%/℃, respectively, suggesting a relatively greater performance decline as temperatures rise. If you would like to learn more about Temperature Coefficient, click the button below to read Maysun Solar’s recent popular blog on Temperature Coefficient!

Maysun Solar has been specialising in producing high quality photovoltaic modules since 2008. Choose from our wide variety of full black, black frame, silver, and glass-glass solar panels that utilise half-cut, MBB, IBC, and Shingled technologies. These panels offer superior performance and stylish designs that seamlessly blend in with any building. Maysun Solar successfully established offices, warehouses, and long-term relationships with excellent installers in numerous countries! Please contact us for the latest solar panel quotations or any PV-related inquiries. We are excited to assist you.

New Photovoltaic news you should know about (March 2024)

Table of Contents REC Unveils a 430 W Heterojunction Solar Module Boasting 22.2% Efficiency REC, a Singapore-based PV module manufacturer, introduces its residential solar modules featuring Alpha heterojunction cell technology. Production has commenced at REC’s Industry 4.0 fab in Singapore, with initial shipments

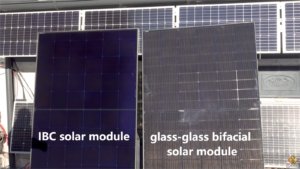

IBC Solar Modules vs. Bifacial Glass-Glass Solar Modules: Which Is More Suitable for Winter or Low-Light Conditions?

Table of Contents Introduction As the demand for renewable energy continues to surge, advancements in solar technology have broadened the spectrum of component choices available to us. Among these, IBC (Interdigitated Back Contact) full black solar modules have garnered special attention due to

Why Are Lightweight Bifacial Solar Panels the Best Choice for Balcony Solar Power Plants?

Table of Contents In the quest for efficient and eco-friendly home energy solutions, solar photovoltaic technology has emerged as a key player due to its sustainability and clean energy benefits. Particularly in the space-constrained urban settings, the effective conversion of every inch of

Questions You Might Ask About Balcony Solar Power Plants in 2024

Table of Contents What is a Balcony Solar Power Plant? Similar to a traditional photovoltaic panel, a Balcony Solar Power Plant is a device designed to generate electricity from solar energy. This green energy generator is specifically tailored for self-consumption, but it comes with

A Step-by-Step DTU Guide for Balcony Solar Power Plants

As renewable energy becomes increasingly integral in our daily lives, Maysun Solar’s Balcony Solar Power Station, with its advanced technology and user-friendly design, represents a transformative approach to home solar solutions. The integration of a Data Transfer Unit (DTU) enhances its smart functionality

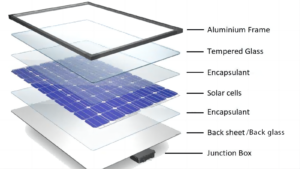

What Are The Main Components of Solar Panels?

What are the main components of solar panel? Solar panels, the cornerstone of solar energy technology, are composed of several integral parts, each contributing to their ability to harness sunlight and convert it into electrical energy. In this article, we will explore the essential