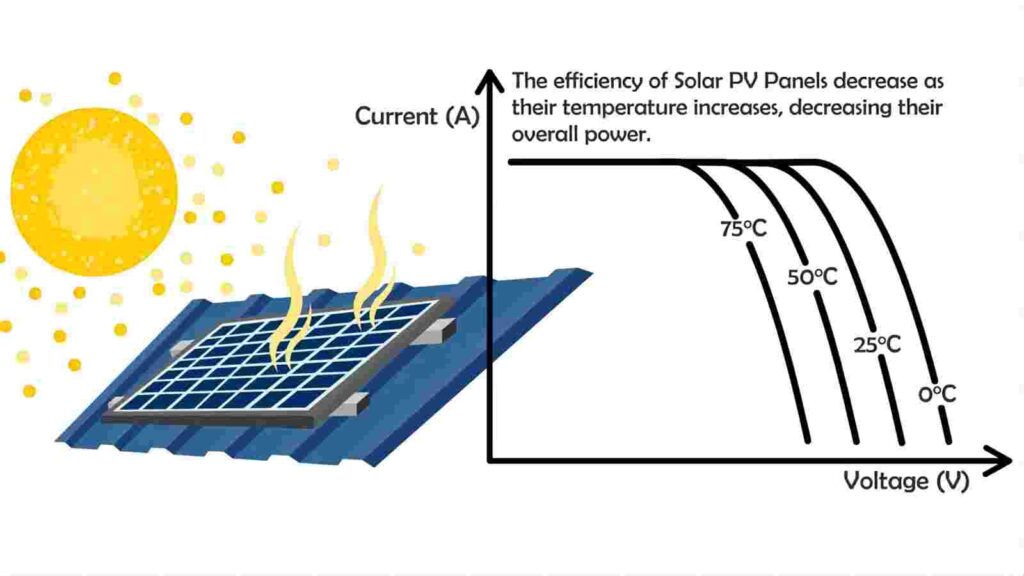

Sunny days are perfect for generating solar energy, but all solar panels lose some of their performance when sunlight is accompanied by too much heat. This needs to be taken into account when you are choosing solar panels and calculating the long-term savings in energy costs. To express the performance of a particular solar panel at high temperatures, solar manufacturers use a measurement called the “temperature coefficient”. The lower the temperature coefficient, the better the solar panel will perform in hot weather. In this article, we will explore the definition, types of temperature coefficient and why it is so critical to solar panels.

Table of Contents

What is the Temperature Coefficient?

In the realm of solar panel performance, a vital yet frequently overlooked parameter is the temperature coefficient. Far more than just a technical measure, this coefficient unveils the adaptability of solar panels to varying temperatures. It specifically quantifies the loss in power output when a solar panel’s temperature surpasses the 25°C (77°F) baseline set under Standard Test Conditions (STC). Typically, the temperature coefficient is articulated as a percentage change per degree Celsius (%/°C) or per degree Fahrenheit (%/°F).

Consider, for example, a solar panel with a temperature coefficient of -0.35%/°C. This indicates that with each degree Celsius rise in temperature above the STC’s 25°C, the panel’s maximum power output diminishes by 0.35%.

It’s crucial to recognize that the temperature coefficient is determined under STC, which encompasses a panel temperature of 25°C, solar irradiance of 1000 W/m², and an air mass of 1.5. This coefficient serves as a pivotal indicator of how stable a solar panel’s performance is under various temperature conditions. Practically, this translates to the panel’s output power being influenced in environments with temperatures significantly deviating from 25°C.

What are the Main Types of Temperature Coefficients?

The temperature coefficient plays a significant role in the efficiency of solar panel power generation. A thorough comprehension of temperature coefficients, particularly those pertinent to Voc (Open-Circuit Voltage), Isc (Short-Circuit Current), and Pmax (Maximum Power), is critical for maximizing energy output. The following discussion delves into these three temperature coefficients and their impacts:

Open-Circuit Voltage (Voc) Temperature Coefficient:

Positive/Negative Coefficient: The Voc temperature coefficient may be either positive or negative. While a positive coefficient, indicating an increase in open-circuit voltage with rising temperature, is relatively rare, a negative coefficient is more common. This means that the open-circuit voltage typically decreases as temperatures rise.

Impact: With a general range between -0.3% to -0.5% per degree Celsius, the negative temperature coefficient of Voc underscores the necessity to anticipate and mitigate temperature’s effects on open-circuit voltage in both the design and operational phases of solar panels.

Short-Circuit Current (Isc) Temperature Coefficient:

Negative Trend: Echoing the pattern seen with Voc, the Isc temperature coefficient usually displays a negative trend, suggesting that the short-circuit current diminishes as temperature increases.

Numerical Range: The Isc temperature coefficient often lies between -0.04% to -0.5% per degree Celsius, highlighting the critical need to evaluate the short-circuit current in light of temperature variations.

Maximum Power (Pmax) Temperature Coefficient:

Comprehensive View: The Pmax coefficient amalgamates the effects of both Voc and Isc coefficients. It offers a holistic perspective on how maximum power output is influenced by temperature changes. The Maximum Power Temperature Coefficient (Pmax) stands out as the most referenced metric to gauge temperature’s impact on solar panel efficiency.

Negative Percentage: Expressed typically within a range of -0.2% to -0.5% per degree Celsius, this coefficient is vital for gauging the overall effect of temperature on solar panel efficiency.

How to Calculate the Temperature Coefficient?

The process of calculating the temperature coefficient for solar panels involves several steps. Here is a comprehensive guide:

Apply Formulas:

Utilize the following formulas for each coefficient:

Voc Temperature Coefficient (αVoc):

αVoc = [(Voc – Vocref) / Vocref] / (T – Tref)

Isc Temperature Coefficient (αIsc):

αIsc = [(Isc – Iscref) / Iscref] / (T – Tref)

Pmax Temperature Coefficient (αPmax):

αPmax = [(Pmax – Pmaxref) / Pmaxref] / (T – Tref)

Note:

T represents the current temperature.

Tref is the reference temperature (typically 25°C).

Vocref, Iscref, and Pmaxref are the respective reference values at Tref.

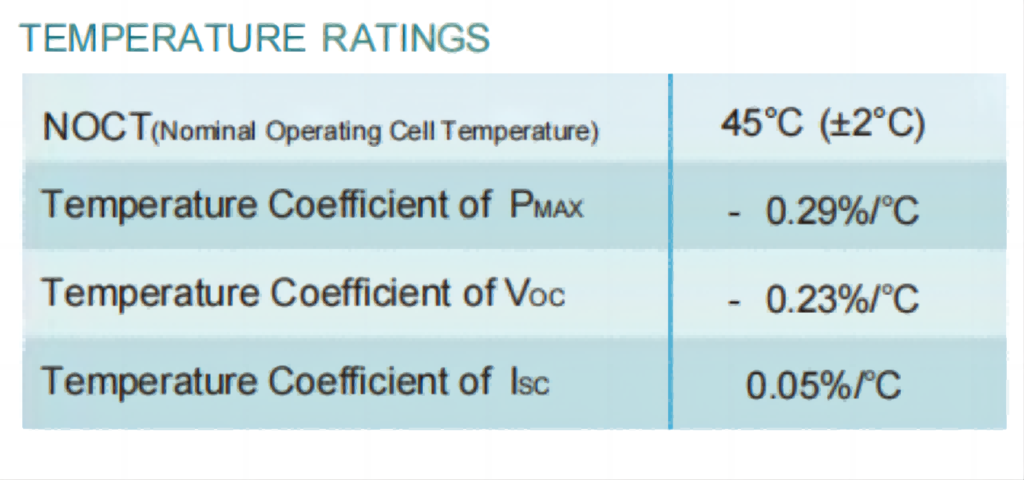

We can usually look for this indicator on the product detail page or datasheet of the solar panel. The graph below shows the temperature coefficient of Maysun Solar IBC full black solar panels:

Why is Temperature Coefficient Important for Solar Panels?

Under high-temperature conditions (40°C ambient temperature), comparing the power degradation of IBC solar panels with a temperature coefficient of 0.29%/°C and PERC solar panels with a temperature coefficient of 0.34%/°C, we first need to consider several key factors that contribute to the rise in the working temperature of solar panels. These factors include:

1.High Ambient Temperature: Directly raises the initial temperature of the panels.

2.Intense Solar Radiation: Causes the panels to absorb more heat, further increasing the temperature.

3.Insufficient Cooling: Inadequate cooling can lead to higher panel temperatures.

4.Dense Installation or Obstructions: These can cause localized increases in the temperature of the panels.

Considering these factors, we can estimate the working temperatures of both types of solar panels under a 40°C ambient environment, and then calculate their power degradation.

1.Estimating Working Temperature:

Ambient temperature of 40°C.

The working temperature might exceed the normal estimated increase of 25°C, potentially reaching an increase of 40°C or more.

Therefore, the working temperature could be 80°C or higher.

To accurately assess the impact of high temperatures on the performance of solar panels, we can use a simple formula to estimate power degradation. The formula is:

Power Degradation = (Actual Working Temperature – STC Temperature) × Temperature Coefficient

2.IBC Solar Panels (Temperature Coefficient of 0.29%/°C):

Increase in working temperature: 80°C – 25°C = 55°C.

Power Degradation = 55°C × 0.29%/°C = 15.95%.

3.PERC Solar Panels (Temperature Coefficient of 0.34%/°C):

Increase in working temperature: 55°C.

Power Degradation = 55°C × 0.34%/°C = 18.7%.

Under such high-temperature conditions, the power degradation of IBC and PERC solar panels is 15.95% and 18.7%, respectively. This indicates that IBC solar panels exhibit relatively less performance degradation under high temperatures. Moreover, the gap in power degradation between the two types of panels widens as the working temperature increases. Therefore, the temperature coefficient of solar panels is an important consideration for energy efficiency and long-term operational stability in high-temperature environments.

In this context, Maysun Solar’s IBC solar panels, with their exceptional temperature coefficient of -0.29%/°C, offer a significant advantage. This superior temperature coefficient reduces the impact of high temperatures on the panels’ functionality, minimizing the effect on power generation. Choosing Maysun Solar’s IBC panels could be a wise decision for those looking to maximize efficiency and performance in challenging high-temperature conditions.

Maysun Solar has been specialising in producing high quality photovoltaic modules since 2008. Choose from our wide variety of full black, black frame, silver, and glass-glass solar panels that utilise half-cut, MBB, IBC, and Shingled technologies. These panels offer superior performance and stylish designs that seamlessly blend in with any building. Maysun Solar successfully established offices, warehouses, and long-term relationships with excellent installers in numerous countries! Please contact us for the latest module quotations or any PV-related inquiries. We are excited to assist you.

New Photovoltaic news you should know about (March 2024)

Table of Contents REC Unveils a 430 W Heterojunction Solar Module Boasting 22.2% Efficiency REC, a Singapore-based PV module manufacturer, introduces its residential solar modules featuring Alpha heterojunction cell technology. Production has commenced at REC’s Industry 4.0 fab in Singapore, with initial shipments

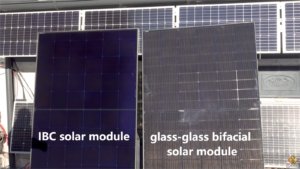

IBC Solar Modules vs. Bifacial Glass-Glass Solar Modules: Which Is More Suitable for Winter or Low-Light Conditions?

Table of Contents Introduction As the demand for renewable energy continues to surge, advancements in solar technology have broadened the spectrum of component choices available to us. Among these, IBC (Interdigitated Back Contact) full black solar modules have garnered special attention due to

Why Are Lightweight Bifacial Solar Panels the Best Choice for Balcony Solar Power Plants?

Table of Contents In the quest for efficient and eco-friendly home energy solutions, solar photovoltaic technology has emerged as a key player due to its sustainability and clean energy benefits. Particularly in the space-constrained urban settings, the effective conversion of every inch of

Questions You Might Ask About Balcony Solar Power Plants in 2024

Table of Contents What is a Balcony Solar Power Plant? Similar to a traditional photovoltaic panel, a Balcony Solar Power Plant is a device designed to generate electricity from solar energy. This green energy generator is specifically tailored for self-consumption, but it comes with

A Step-by-Step DTU Guide for Balcony Solar Power Plants

As renewable energy becomes increasingly integral in our daily lives, Maysun Solar’s Balcony Solar Power Station, with its advanced technology and user-friendly design, represents a transformative approach to home solar solutions. The integration of a Data Transfer Unit (DTU) enhances its smart functionality

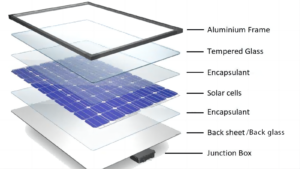

What Are The Main Components of Solar Panels?

What are the main components of solar panel? Solar panels, the cornerstone of solar energy technology, are composed of several integral parts, each contributing to their ability to harness sunlight and convert it into electrical energy. In this article, we will explore the essential

Pingback: 2023 Guide of IBC Solar Panels: Why Choose IBC Solar Panels? - Professional Distributed PV Module Manufacturer

Pingback: What Are Heterojunction Technology (HJT) Solar Panels: Advantages & Applications - Professional Distributed PV Module Manufacturer