Table of Contents

What is Potential Induced Degradation (PID) Effect in solar panels?

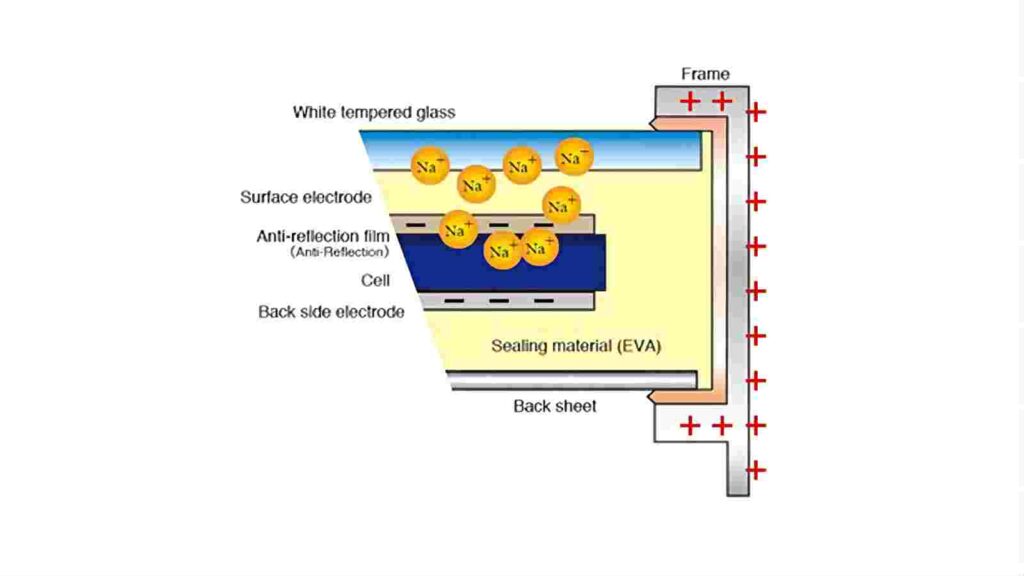

Potential Induced Degradation (PID) in solar panels stems from a notable potential difference between the semiconductor material (cell) and other components of the module, such as glass, mounts, or the aluminum frame. This voltage disparity induces current leakage, prompting the migration of negative and positive ions. Negative ions exit through the aluminum frame, while positive ions, particularly sodium ions, travel to the cell surface. This process essentially “pollutes” the cell, diminishing its photovoltaic effect and resulting in power losses. PID effects can lead to significant power losses, potentially reaching up to 20%, and the consequences are not immediately evident – the manifestation of these effects may take several months to a few years to become apparent.

Why does Potential Induced Degradation (PID) Effect occur?

Potential Induced Degradation (PID) Effect Usually occurs in long-term use of solar photovoltaic systems, especially in high temperature, high humidity environments.

1.High Temperature and Humidity:

High temperature and humidity stand as the primary instigators of Potential Induced Degradation (PID) in solar panels. Increased humidity leads to the accumulation of moisture on the panel surface, establishing conductive pathways and triggering potential differences and PID effects. Furthermore, heightened humidity fosters the migration of charge carriers, resulting in uneven current distribution and a subsequent decline in performance.

As temperatures rise, alterations in semiconductor properties, heightened electron mobility, and accelerated potential difference formation exacerbate PID effects, ultimately causing material degradation within the solar panels. The combined impact of elevated humidity and temperature intensifies these effects, with humidity facilitating water vapor adsorption and high temperatures accelerating evaporation, thereby magnifying potential differences.

2.System Configuration:

The configuration of the PV system, including grounding, module type, and cell type, plays a significant role in PID. The voltage potential and the polarity of the module impact the occurrence of PID. This dependence is influenced by the panel’s position in the array and the grounding of the system. Typically, PID is associated with a negative voltage potential to earth, making the more negatively charged panel more susceptible to PID risks.

3. Loads on the Glass Surface:

If the glass surface of the solar panel carries loads, such as dust or other contaminants, this can increase the potential difference and lead to the PID effect.

Various factors related to loads on solar panels contribute to Potential Induced Degradation (PID) effects. Surface damping induced by loads creates a thin film on the glass, increasing surface damping and impeding charge migration. This concentrates potential differences at the surface, disrupting uniform electron distribution, heightening PID risks. Load-induced changes in optical properties, such as altered light absorption, lead to uneven absorption, generating local potential differences exacerbated by strong sunlight. Loads affect thermal conductivity, causing local temperature variations, accelerating electron migration, and increasing potential differences, especially in direct sunlight. Moisture-absorbing loads create a conductive channel, accelerating PID. Frequent cleaning is necessary to reduce potential differences, maintain panel performance, and decrease PID likelihood due to loads.

How to detect the Potential Induced Degradation (PID) Effect ?

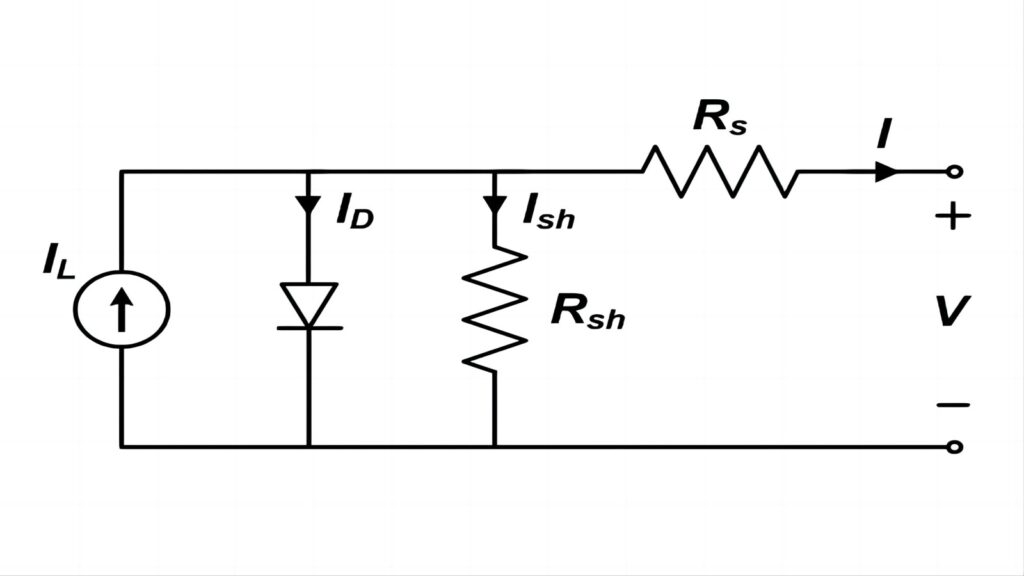

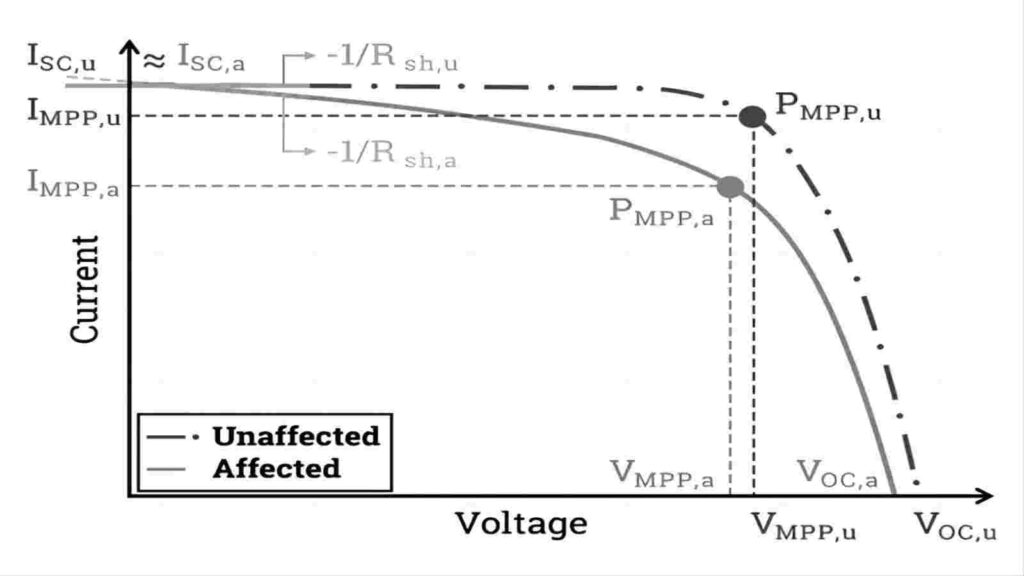

To ascertain whether solar panels are affected by PID, an I-V curve test can be conducted. PID reduces the performance of solar panels by decreasing the shunt resistance of the electrical model (see Figure 1). This corresponds to an increase in leakage current, resulting in a reduction of output current (and thus, total output capacity), and it affects the I-V curve as illustrated in Figure 2.

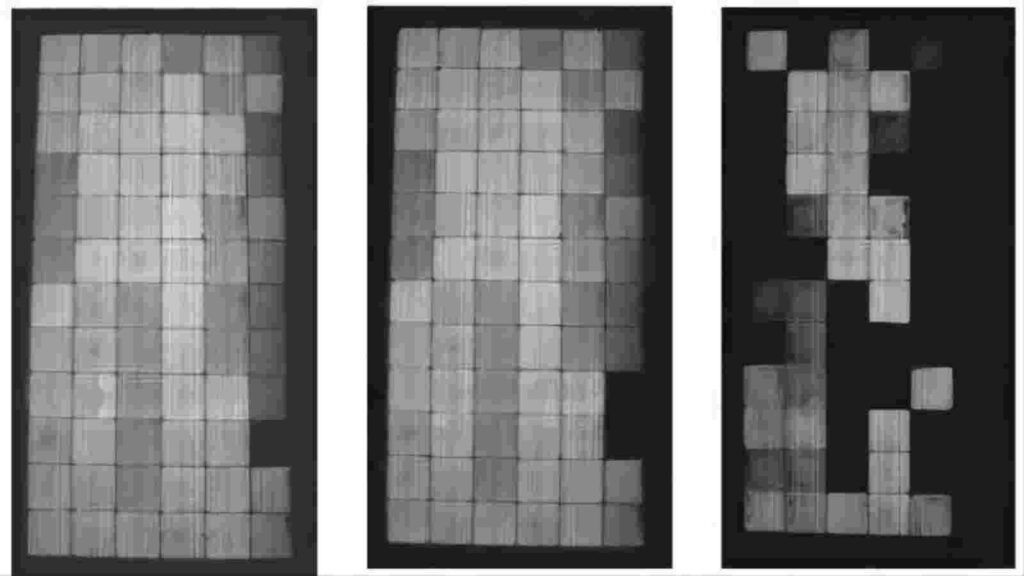

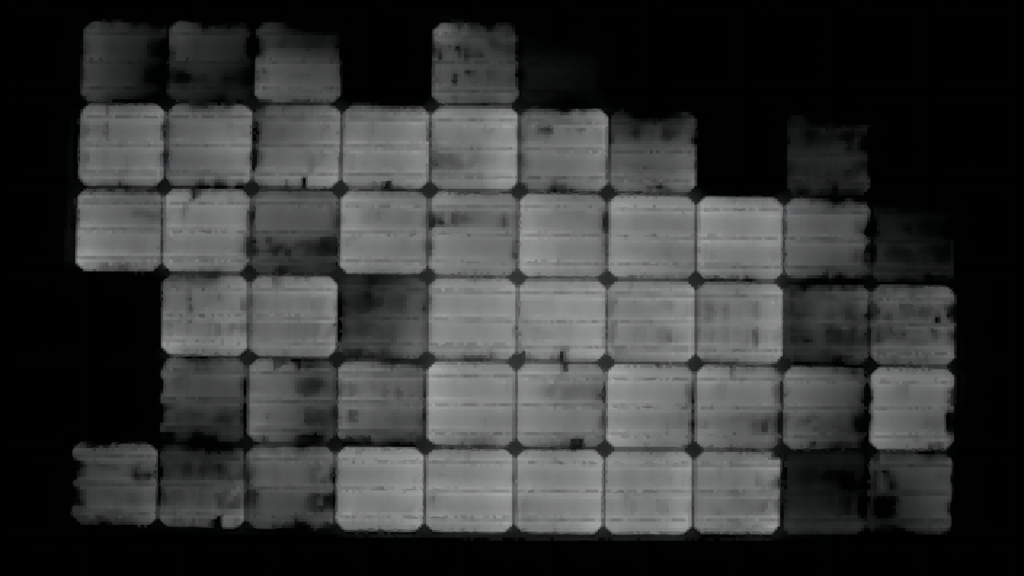

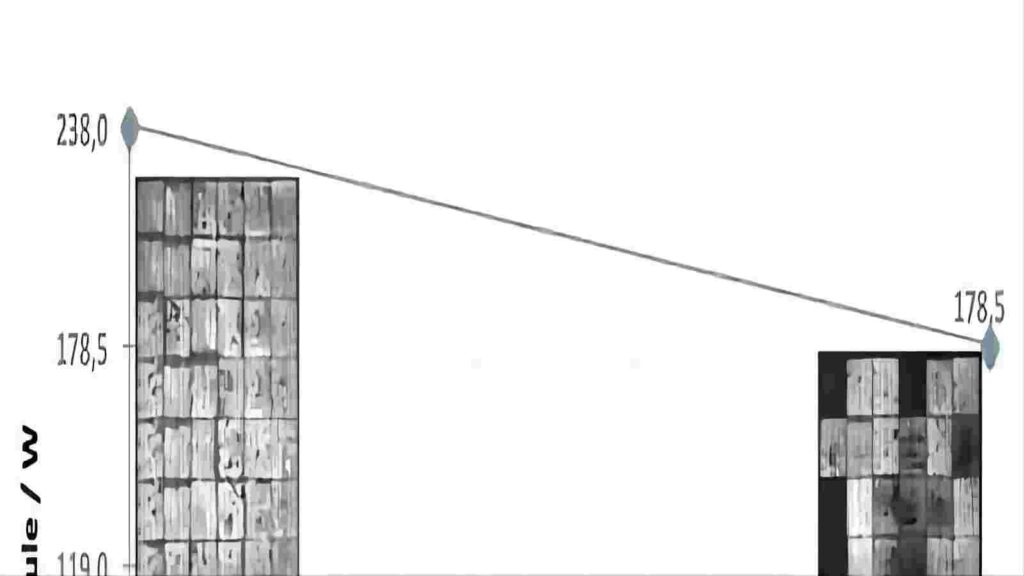

The IEC standard 62804 was established to evaluate the ability of solar panels to endure high voltages without undergoing degradation. The prescribed approach entails exposing solar panels to a DC voltage bias of 1000 V under conditions of 85% relative humidity and a temperature of 60 ºC for a duration of 96 hours. The graph illustrates the Pmpp/W rating (where Pmpp represents the panel’s maximum power), accompanied by images of the panel displaying electroluminescence both before and after the test.

The visual representation above indicates that the PV system encountered a power decrease of approximately 25% during the PID test. According to IEC standard 60924, to meet the specified requirements, this reduction should not surpass 5%. While there may be variations among solar panels, it’s important to note that this standard was established through extensive testing on a diverse array of PV panels.

How to prevent Potential Induced Degradation (PID) Effect ?

The occurrence of PID effects is usually affected by a variety of environmental and operating factors. In order to ensure the stability and performance of the solar panel system, a series of measures need to be taken to prevent and mitigate the impact of the PID effect.

1.Use solar panels with anti-PID technology:

Choose solar panels with anti-PID properties. Some manufacturers use unique cell technologies to mitigate or to mitigate or suppress the occurrence of PID effects, such as HJT solar panels.

Maysun’s HJT (Heterojunction with Intrinsic Thin layer) solar panels effectively prevent Potential Induced Degradation (PID) through the strategic use of a Transparent Conductive Oxide (TCO) film layer on the glass surface. This TCO layer prevents charge polarization, structurally averting PID degradation. Alongside the heterojunction design and intrinsic thin layer, Maysun’s HJT solar panels minimize charge migration, reduce uneven current distribution, and effectively mitigate PID risks, ensuring enhanced stability in challenging environments. Additionally, these panels are certified with the Solar Module Test Module PID Resistance-IEC 62804, ensuring superior quality.

Maysun Solar HJT solar panels have been distributed to several European countries. Customers have shared their satisfaction with the impressive performance and reliability of Maysun HJT solar panels.

https://youtu.be/5bnAJBH7sJs

HJT Solar Panel

2. Optimise system design:

Optimised system design is another key factor in preventing PID effects. Optimise the system design by the following means:

Maximum Power Point Tracker (MPPT): MPPT technology helps to ensure that the panels work at the maximum power point under different light conditions, which reduces the risk of uneven current distribution and slows down the occurrence of PID effect.

Current equalisation technology: The introduction of current equalisation technology helps to maintain an even distribution of current between panels, thus reducing the possibility of PID effects caused by potential potential potential differences.

3.Protective coatings:

The application of dust, water vapour and pollution resistant protective coatings on the surface of solar panels can mitigate the attack of surface contaminants on the panels and reduce the risk of PID effects.

These coatings can include:

Dust Resistant Coatings: Slows down dust deposition and keeps the panel surface clean.

Water vapour resistant coatings: Prevent water vapour penetration and reduce the effect of humidity on potential differences.

Anti-pollution coatings: Reduce the adhesion of grease, bird droppings and other pollutants and maintain the optical transparency of the surface.

4. Regular cleaning:

Regular cleaning of the solar panel surface is a key measure to maintain system performance. Removal of dust, leaves, bird droppings and other loads helps to maintain a clean surface and reduce the formation of potential potential potential differences. Regular cleaning also helps to maintain the panel’s light transmission and improve light absorption efficiency.

Moreover, PID is often reversible. If PID occurs, one mitigation method involves grounding the DC negative terminal of the inverter to prevent negative voltages on the string. This approach is effective when the inverter permits such operation and all necessary design precautions are implemented. Another mitigation strategy is the use of “anti-PID boxes” positioned between the string and the inverter. These boxes invert the potential applied by the inverter to counteract negative voltages on affected solar panels. Their impact is to vary the polarization of each string over time, reducing the likelihood of PIDs and allowing each module to “recover” from the negative potential it experienced.

Since 2008, Maysun Solar has been dedicated to manufacturing top-notch solar panels. Explore our diverse selection, including half-cut, MBB, IBC, HJT, and shingled solar panels available in silver, full black, black frame, and glass-glass finishes. The panels boast exquisite designs and exceptional performance, enhancing the aesthetics of any building. With established offices, warehouses, and enduring partnerships with leading installers across numerous countries, Maysun Solar is a trusted choice. For inquiries about PV or the latest quotes on solar panels, feel free to contact us; we are eager to assist you.

Reference:

Greensolver, & Greensolver. (2021b, November 26). Potential Induced Degradation (PID) – What is it? – Greensolver. Greensolver.

Admin-D3v. (2020, July 6). LID vs PID: What’s degrading your solar panels? Raycatch | AI Diagnostics for Solar Energy.

Was ist der PID-Effekt (Potential Induced Degradation) von Solarmodulen? (n.d.). Was Ist Der PID-Effekt (Potential Induced Degradation) Von Solarmodulen?

Causes and solutions of the potential Induced Degradation (PID) effect in PV modules – Technical articles. (2020, July 9).