Table of Contents

Intro

In the current era of advocating for renewable energy, solar panels, as a clean and sustainable energy option, are gaining increasing attention. However, with the rapid development of solar technology, some common issues and potential challenges with solar panels are gradually coming to light. To ensure the smooth operation and long-term performance of solar energy systems, it is essential to delve into these issues and seek reliable solutions. This article will explore some common problems associated with solar panels and provide solutions for choosing reliable solar panels to help ensure the efficient functioning of solar energy systems.

What Are The Common Failures and Potential Issues Of Solar Panels?

Hot Spot Effect

Solar cells are engineered to produce an electric current when exposed to sunlight. This phenomenon, characterized by localized high-temperature areas on the solar panel surface, arises from uneven current distribution or other factors. As this current traverses through the interconnected strings of solar cells within panels, the inherent resistance in the cells transforms some of the current into heat losses. Any imperfections in the solar cells, such as microcracks, inadequately soldered joints, or mismatches, result in increased resistance, this imbalance can significantly reduce the overall efficiency of the solar panel, and eventually giving rise to hot spots. Over time, the prolonged presence of hot spots can result in burn marks, degrading the integrity of both the solar cells and backsheets. If left unaddressed, these conditions may escalate, posing a potential risk of fires.

Microcracks and Snail Trails

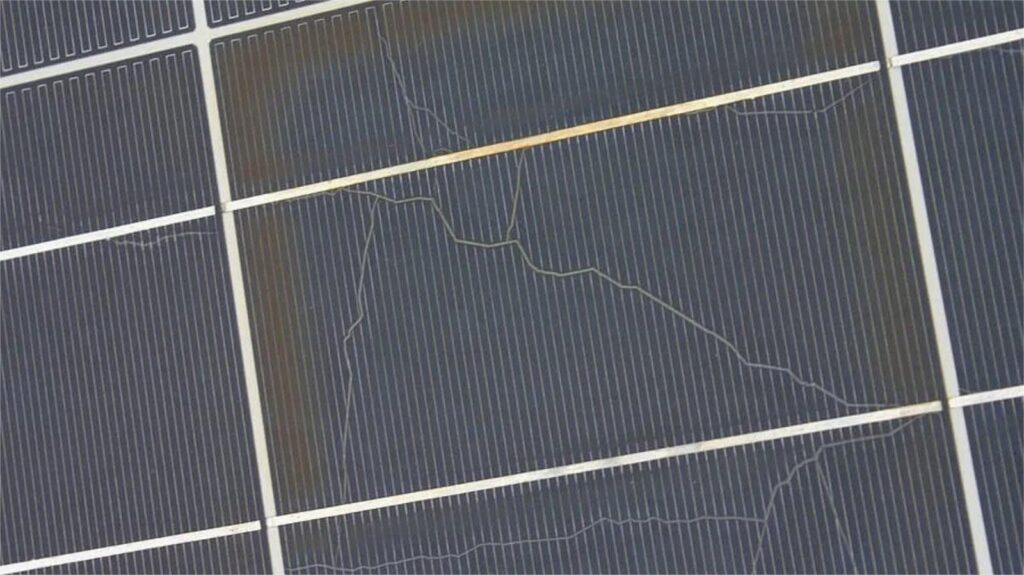

The progress in semiconductor processing has led to ultra-thin solar cells, about 170 μm thick—roughly twice the diameter of a human hair. However, this makes the solar cells brittle, prone to cracking upon forceful impact, resulting in microcracks or snail-like patterns on the panel surface. Microcracks refer to tiny fractures that form on the surface of solar panels, typically caused by stress during the manufacturing process or external impacts. “Snail trail” refers to observable imperfections without magnification, manifesting as slender, dark lines in a spiral configuration. These issues, stemming from manufacturing stresses or external pressures, impact optical and electrical performance. Microcracks and snail trails hinder electric current conduction in compromised cells, reducing energy production and potentially causing hot spots.

Solar Panel Breakage

Solar panels are prone to physical impacts during transportation and installation, leading to potential damage. Simultaneously, they are highly susceptible to thermal stress induced by fluctuations in weather conditions, such as extreme heat or cold, causing significant temperature variations. This thermal expansion and contraction exert pressure on the structural integrity of components like glass, solar cells, and frames, potentially resulting in damage and adversely affecting the overall performance of the solar panels. If the external force is so strong that it breaks the glass while also damaging the cells inside the solar panel, the consequences can be even more serious. Damage to solar cells directly impacts panel performance and efficiency. Cracks or breakages can cause uneven current distribution, reducing overall energy conversion efficiency. This damage also lead to hotspots and performance degradation, compromising the reliability and lifespan of the solar energy system. Maintaining cell integrity is crucial for long-term system operation.

Performance Degradation

Extended usage can result in a decline in performance, involving several aspects such as Light-Induced Degradation (LID), Light and Elevated Temperature-Induced Degradation (LeTID), and Potential-Induced Degradation (PID). LID occurs when solar cells experience reduced efficiency due to exposure to sunlight, while LeTID involves degradation under simultaneous exposure to light and elevated temperatures. PID refers to a decline in performance caused by potential-induced stresses. The cumulative impact of these degradation mechanisms highlights the importance of monitoring and mitigating factors affecting long-term solar panel performance to sustain optimal energy production over time. For a detailed look at solar panel degradation, you can check out Maysun Solar’s blog post on solar panel degradation by clicking the button below.

Backsheet Tearing

The tearing of backsheets, especially during installation, poses a risk to the waterproof performance of solar panels. Solar panels endure daily exposure to intense UV radiation and temperature fluctuations. The presence of cracked backsheets indicates suboptimal component selection, potentially allowing water vapor to penetrate the module laminate and harm solar cells. This underscores the importance of meticulous component choices to mitigate the risks associated with environmental stressors and maintain the longevity and effectiveness of solar energy systems.Regular inspection and preventive measures are essential to address these issues and ensure the sustained efficiency of solar energy systems.

Solutions: Choose Reliable Solar Panels

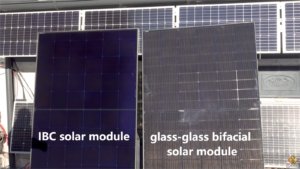

In the face of these common solar panel problems, suppliers have now developed many advanced solar panels, such as IBC solar panels and HJT solar panels, which can effectively avoid the above problems. Let’s take a closer look at what the advantages of IBC solar panels and HJT solar panels to solve these issues!

IBC Solar Panels

No hot spots

IBC solar cells leverage the distinctive All Back Contact technology, where the positive and negative metal electrodes on the rear side maintain normal flow even when solar panels are shaded. This innovative design ensures that there is minimal resistance on the front side, effectively mitigating the potential damage caused by hot spots on the module. By eliminating resistance on the front side, this technology not only reduces the risk of hot spot formation but also minimizes potential operational risks for the entire solar power plant.

High reliability

IBC solar panels offer significant advantages in this regard. By eliminating the conventional Z-soldering process for the cell welding strip, the number of solder joints in IBC solar panels is reduced by 80% compared to TOPCon. This modification eliminates the risk of false soldering or over-soldering, resulting in a substantial improvement in the reliability and stability of the IBC solar panels.

Higher weather resistance

IBC solar panels have high weather resistance, the sophisticated All Back Contact design prevents tension-related damage and detachment resulting from the thermal expansion and contraction of the front welding strip when the solar panel experiences significant temperature stress. This design ensures that IBC solar panels minimize the impact of thermal stress, reducing the effects of thermal expansion and contraction under varying temperature conditions. By mitigating the structural pressures on components such as glass and solar cells, it prevents excessive stress that could lead to damage. The result is a stable generation performance, safeguarding against the negative effects of thermal stress and maintaining the integrity of the solar panels.

Anti-LID effect

One of the advantages of IBC solar panels is anti-LID effect . The exceptional resistance to moisture significantly mitigates the degradation of solar panels caused by various environmental stressors. This includes the reduction of Light Induced Degradation (LID), Light and elevated Temperature Induced Degradation (LeTID), and UV Induced Degradation (UVID). Superior moisture resistance ensures that these panels are better equipped to withstand the detrimental effects of prolonged exposure to light, elevated temperatures, and ultraviolet radiation, which are known contributors to performance degradation in traditional solar technologies. By minimizing the impact of these degradation mechanisms, solar panels with enhanced moisture resistance can exhibit prolonged efficiency and stability over their operational lifespan, providing a more reliable and durable clean energy solution. This is one of the top reasons why IBC solar panels turned out to be more and more popular.

Sturdy and waterproof backsheet

IBC solar panels feature a backsheet coated with a PVF Tedlar film, enhancing their waterproof performance. This advanced design ensures superior water resistance, contributing to the overall durability and reliability of the solar panels. The use of PVF Tedlar membrane as a backsheet not only enhances the protection against moisture ingress but also extends the lifespan of the panels, making IBC solar panels an ideal choice for applications where robust waterproofing is crucial for long-term performance.

Maysun Solar’s latest IBC solar panels seamlessly integrate the benefits of IBC solar cells, offering high efficiency, aesthetic appeal, and an extended lifespan. Choosing Maysun Solar’s IBC solar panels is a smart decision for those looking to maximize efficiency and overall performance. The picture below shows the Maysun Solar IBC black frame solar panels installed by Maysun Solar’s Italian customer. For further details, feel free to click the button below!

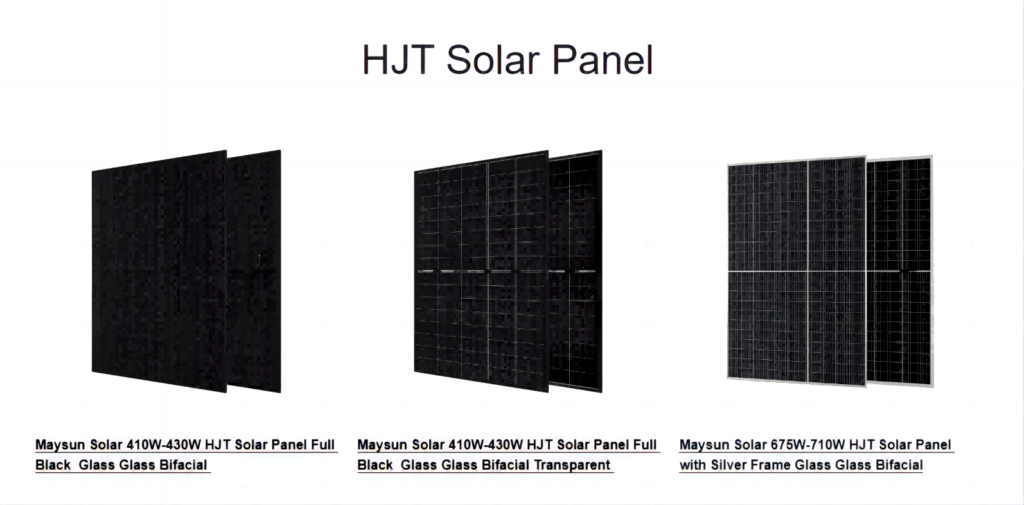

HJT Solar Panels

Low degradation

There is no possibility of electronic on the surface of HJT cells, so there is no LID and LeTID effects. The first year’s power degradation for HJT solar panels is 1%, and the average annual degradation after that is 0.35%. The power generation capacity of heterojunction solar panels will not decay by more than 11.5% in 30 years. Therefore, the power generation of HJT solar panels will be more stable during the life cycle.

Stronger PV material

HJT solar panel comes with a robust 30-year product warranty, providing customers with long-term assurance of its durability and performance. This extended guarantee is attributed to the utilization of weather-resistant, corrosion-resistant, and wear-resistant double-sided semi-tempered glass, coupled with POE encapsulation technology. The double-sided semi-tempered glass not only enhances the HJT solar panel’s resilience against adverse weather conditions but also contributes to its resistance against corrosion and wear over time, to reduce the incidence of glass breakage. The POE encapsulation further ensures the integrity of the solar panel, providing a comprehensive safeguard that extends both its longevity and performance. This combination of advanced materials and encapsulation technologies reinforces HJT solar panel’s reliability, making it a dependable choice for sustainable and enduring solar energy solutions.

Effective reduction of microcracks

Effectively mitigating the formation of microcracks, Heterojunction (HJT) technology employs No-Cut solar cells and a low-temperature manufacturing process. HJT solar cells feature a more extensive and refined busbar design, contributing to an improved stress distribution on the cell surface. This design helps minimize stresses caused by thermal expansion, optimizes current distribution, thereby reducing the risk of microcrack formation and busbar breakage. These design adjustments contribute significantly to enhancing the performance and reliability of HJT solar panels. The innovative approach enhances the stability and durability of solar cells, offering a reliable solution for sustained performance in photovoltaic systems.

Low temperature coefficient

Compared to PERC and TOPCon solar cells, Heterojunction (HJT) solar cells exhibit a lower temperature coefficient (-0.24%/°C), resulting in a more stable power generation performance in high-temperature environments and reduced power losses. This characteristic enhances the overall efficiency and reliability of HJT solar cells, making them particularly advantageous for applications where temperature variations are a significant factor.

Explore the forefront of renewable energy innovation with Maysun Solar’s Heterojunction (HJT) solar panels. Leveraging the unparalleled advantages of Heterojunction Technology, our panels mark a significant advancement in solar power efficiency. Engineered with cutting-edge heterojunction technology, these panels ensure a consistent, high voltage output even in low-light conditions. With a low-temperature coefficient (-0.243%/°C), they ensure sustained performance in hotter climates, extending effective energy generation. Showcasing an impressive bifacial rate of 95%, Maysun Solar’s HJT panels optimize solar energy absorption, greatly enhancing the energy yield of your photovoltaic system. For a more in-depth understanding of the capabilities of HJT solar panels, click the button below and embark on a journey toward cleaner, more efficient energy solutions!

Conclusion

Common problems with solar panels include hot spot effect, solar panel breakage, performance degradation and backsheet tearing, etc. Choosing reliable and high quality solar panels can minimise these problems and reduce maintenance work and trouble. At the same time, it can effectively reduce LCOE costs and achieve greater economic benefits. LCOE (Levelized Cost of Electricity) is a metric that primarily signifies the average cost required to generate one unit of electricity, commonly measured in kilowatt-hours (kWh). This metric comprehensively considers total costs, investments, operational and maintenance expenses, as well as electricity output. A lower LCOE value indicates not only reduced overall costs, including diminished investment and operational maintenance expenses but also denotes higher efficiency in electricity generation. Click the button below to read the article and learn more about LCOE!

Maysun Solar has been dedicated to manufacturing top-tier photovoltaic modules since 2008. Explore our extensive range of solar panels, including full black, black frame, silver, and glass-glass options, all incorporating cutting-edge technologies such as half-cut, MBB, IBC, HJT, and Shingled. These panels are designed for superior performance and boast stylish aesthetics that seamlessly integrate with any architectural setting. Maysun Solar has successfully established offices, warehouses, and enduring partnerships with skilled installers across numerous countries. For the latest module quotations or any inquiries related to photovoltaics, please feel free to reach out. We are eager to assist you in harnessing the power of solar energy.

New Photovoltaic news you should know about (March 2024)

Table of Contents REC Unveils a 430 W Heterojunction Solar Module Boasting 22.2% Efficiency REC, a Singapore-based PV module manufacturer, introduces its residential solar modules featuring Alpha heterojunction cell technology. Production has commenced at REC’s Industry 4.0 fab in Singapore, with initial shipments

IBC Solar Modules vs. Bifacial Glass-Glass Solar Modules: Which Is More Suitable for Winter or Low-Light Conditions?

Table of Contents Introduction As the demand for renewable energy continues to surge, advancements in solar technology have broadened the spectrum of component choices available to us. Among these, IBC (Interdigitated Back Contact) full black solar modules have garnered special attention due to

Why Are Lightweight Bifacial Solar Panels the Best Choice for Balcony Solar Power Plants?

Table of Contents In the quest for efficient and eco-friendly home energy solutions, solar photovoltaic technology has emerged as a key player due to its sustainability and clean energy benefits. Particularly in the space-constrained urban settings, the effective conversion of every inch of

Questions You Might Ask About Balcony Solar Power Plants in 2024

Table of Contents What is a Balcony Solar Power Plant? Similar to a traditional photovoltaic panel, a Balcony Solar Power Plant is a device designed to generate electricity from solar energy. This green energy generator is specifically tailored for self-consumption, but it comes with

A Step-by-Step DTU Guide for Balcony Solar Power Plants

As renewable energy becomes increasingly integral in our daily lives, Maysun Solar’s Balcony Solar Power Station, with its advanced technology and user-friendly design, represents a transformative approach to home solar solutions. The integration of a Data Transfer Unit (DTU) enhances its smart functionality

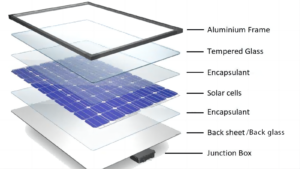

What Are The Main Components of Solar Panels?

What are the main components of solar panel? Solar panels, the cornerstone of solar energy technology, are composed of several integral parts, each contributing to their ability to harness sunlight and convert it into electrical energy. In this article, we will explore the essential