Welcome to our comprehensive guide on half-cut solar panel technology. This article will talk about half-cut solar panels. We will discuss their benefits, drawbacks, and how to take care of them. Half-cut solar panels are becoming more popular due to their superior efficiency and performance, as the demand for maximizing solar energy generation continues to grow. Come along with us on a journey to learn about the benefits and upkeep of half-cut solar panels. Whether you’re a homeowner, business owner, or just interested in renewable energy, we welcome you! Let’s use this new technology to create a better future that is sustainable.

You will see the following content:

What is half-cut solar panel?

Solar energy is a clean and renewable source of power that is becoming more popular for meeting our energy needs. Half-cut solar panels are a new type of photovoltaic component that has been developed thanks to advancements in solar technology. What are half-cut solar panels?

Half-cut solar panels are made by cutting traditional silicon solar cells into two or more halves using a non-destructive technique. This technique improves how well and how efficiently the solar panels work. Most solar panels use cells made from a single wafer, which can have some problems like shading losses and uneven current distribution. Half-cut solar panels allow each small cell to work independently with its own contact points. This is different from other types of solar panels.

Half-cut solar panels have some benefits over regular solar panels. The half-cut technology helps to reduce shading losses, which leads to better conversion efficiency for the photovoltaic system. Every tiny cell works on its own, making the most of solar energy. Also, solar panels that are cut in half have a lower operating temperature called the Nominal Operating Cell Temperature (NOCT). This helps them perform better even in places with high temperatures. Half-cut solar panels can be made in different shapes and sizes. Solar panel manufacturers can create different shapes and sizes of half-cut solar panels to fit specific needs.

How do half-cut solar panels work?

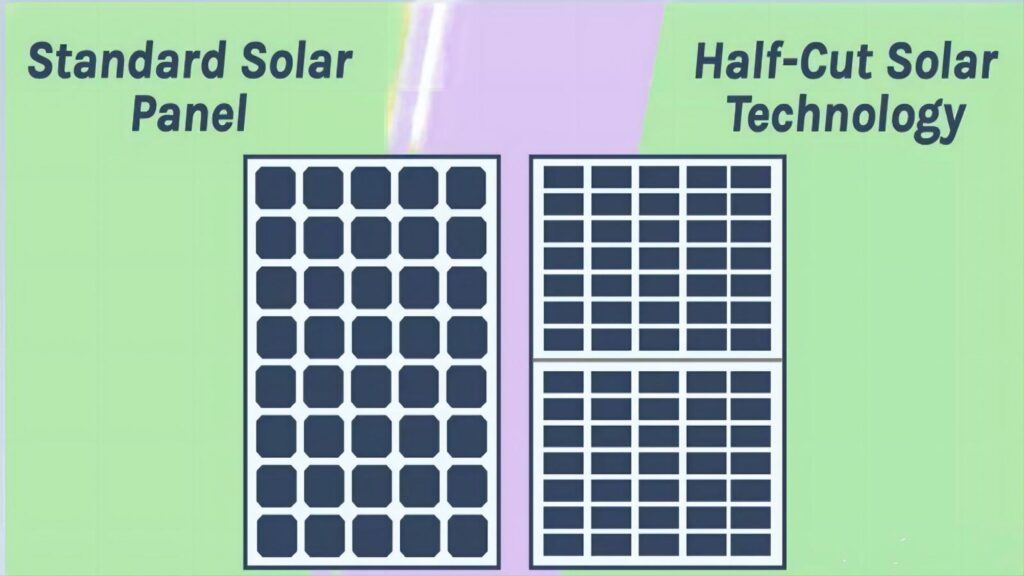

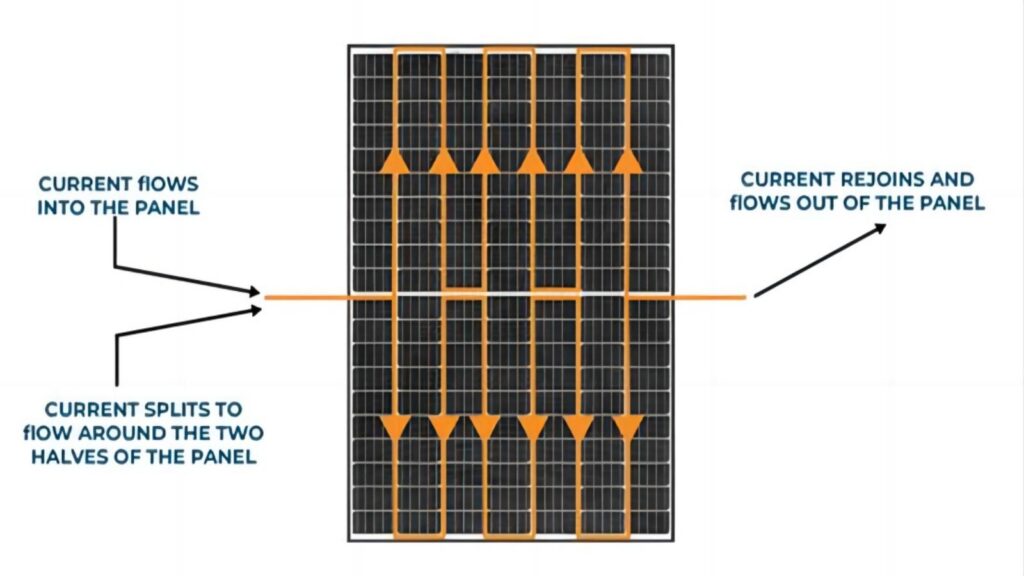

Typically, solar panels have 60 to 72 cells. However, if we cut them in half, we can double the number of cells. These half-cut panels typically have 120 to 144 cells. Laser technology is used to carefully split the cells, which reduces drag and improves performance. When the cells are smaller, more cells can fit on the panel. If the panel is split in half, each section can work independently and generate electricity even if one half is in the shade.

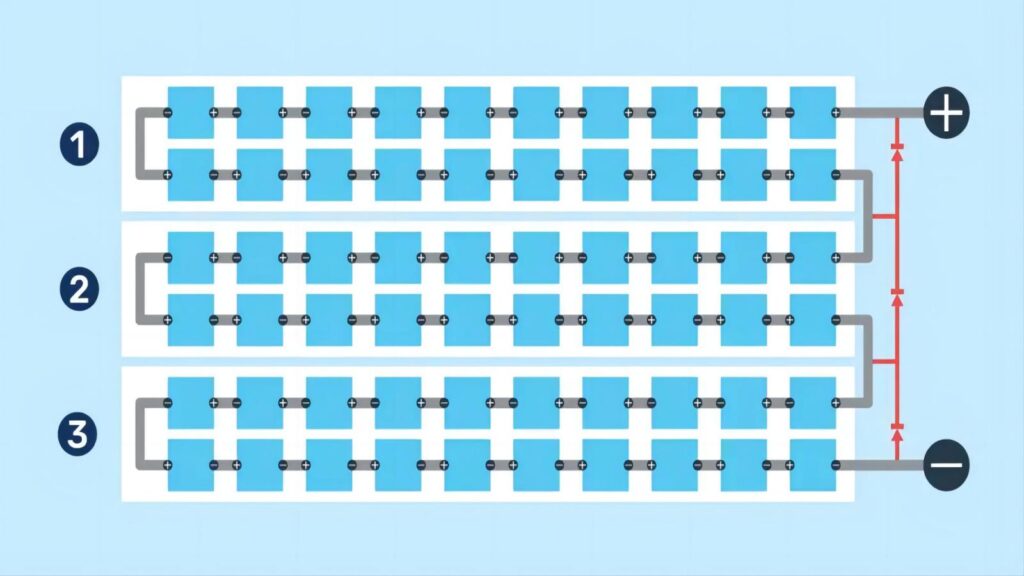

With conventional full-cell string wiring, if the solar cells in row 1 do not get enough sunlight, each cell in the series will not produce energy. This eliminates one-third of the panel.

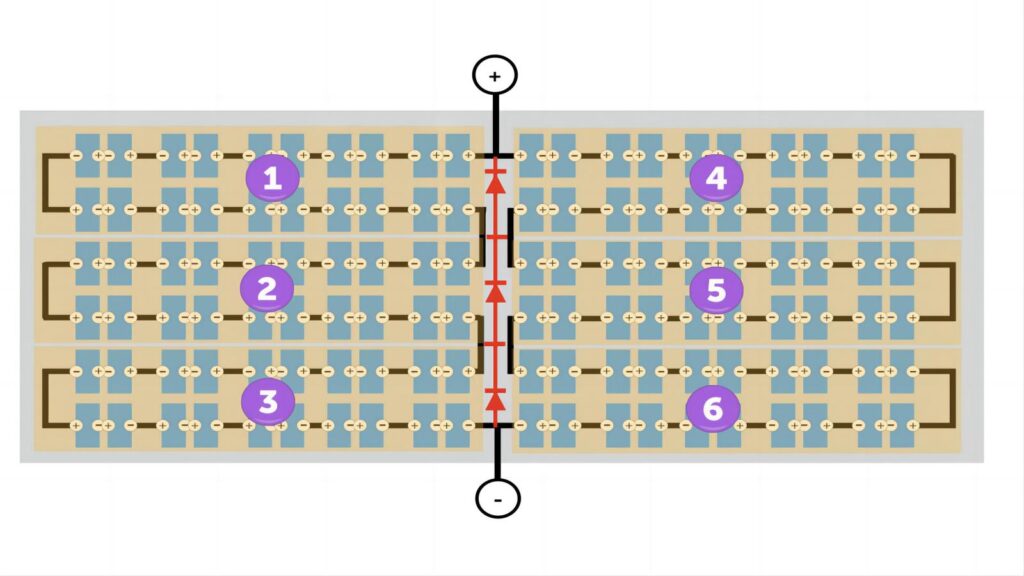

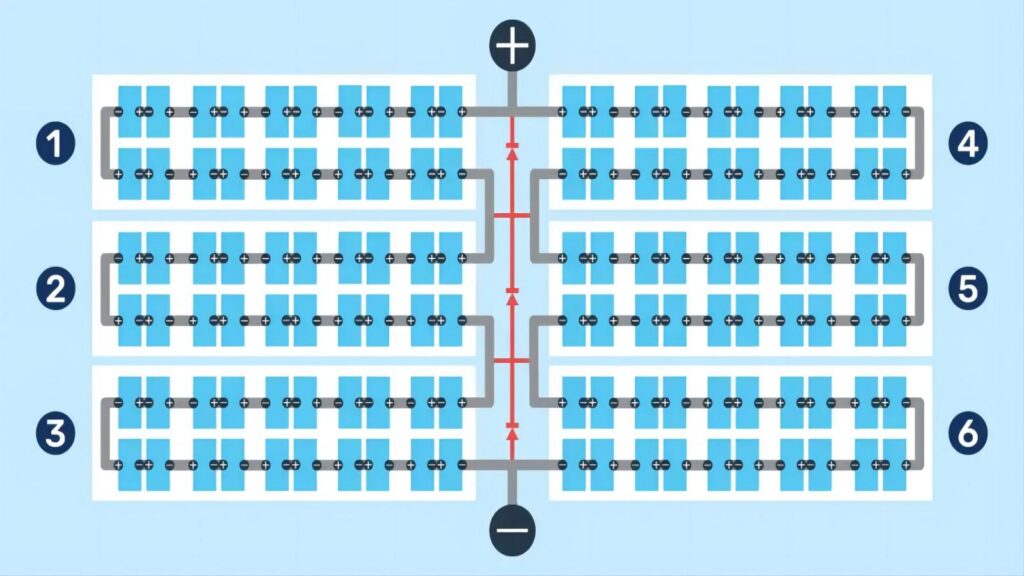

The half-cut cell design, however, uses a special “serial wiring” technique that connects the solar cells with bypass diodes to transfer power. As shown in the figure below, if the solar cell in row 1 is shaded, the cells in that row (and only that row) will stop generating power. Row 4 will continue to generate more power than conventional series wiring, as only one-sixth of the panels stop generating power, instead of one-third.

The comparison shows that if a conventional solar panel has a shaded or damaged cell in one row, the entire row will not produce power. In contrast, if a half-cut panel is shaded, the portion that stops generating power is relatively smaller. This increases the overall energy production. This is different from other panels that cannot do this.

Half-cut technology has many benefits over traditional panels. These include higher cell numbers, lower resistance, better power output, and better reliability. These improvements increase the efficiency and reliability of half-cut solar panels in capturing solar energy.

Simply put, half-cut solar panels function by making the cells smaller, increasing their number, and splitting the panel into two separate sections. This design makes solar power generation more efficient and reliable, even in partially shaded areas.

What are the benefits of using half-cut solar panels?

Reduced Resistive Losses: Half-cut solar panels can reduce resistive losses. They do this by dividing solar cells in half, which lowers the current produced by each cell. This enhances energy conversion efficiency.

Enhanced Shade Tolerance: Half-cut solar panels have a wiring configuration that makes them more resistant to shading. Half-cut panels have less power loss when some cells are shaded, as compared to regular panels. This means that the cells will continue to generate power without any blockages, which will result in a steady and reliable power output.

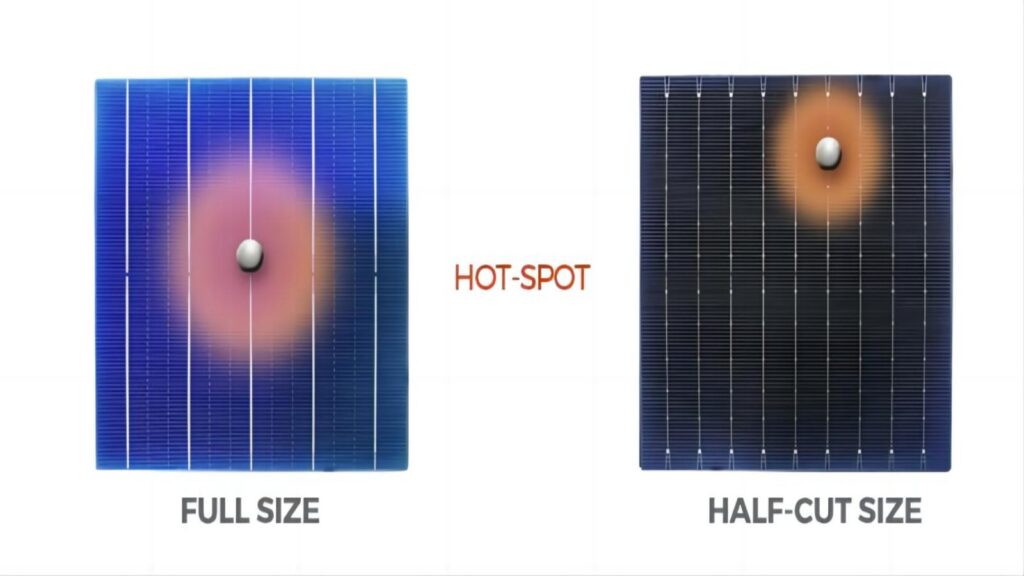

Mitigated Hot Spot Effects: Half-cut solar panels are designed to reduce hot spots. If some cells are shaded, the other cells that are not shaded will help to spread the heat across more cells. This will make it less likely for the panel to have hot spots and will make the components last longer.

Increased Module-Level Power: Half-cut solar panels produce more power at the module level. These panels are designed to have less energy loss and better wiring, which makes them more efficient and produce more energy.

Compatibility with Diverse Solar Cell Technologies: Half-cut solar panels work well with different types of solar cell technologies, including PERC and bifacial technology. Their versatility helps them use various technologies to reduce power losses, increase power output, and gain other advantages.

To sum up, using half-cut solar panels can greatly enhance the efficiency and dependability of solar power systems. Today, people really want advanced solar technology that can make things more efficient, work in shady areas, prevent overheating, and work with different types of solar cells. This is why people really like this technology.

What are the downsides of using half-cut solar panels?

Higher Manufacturing Costs: Half-cut solar panels require a more complex production process than traditional panels, which can make them more expensive to manufacture. Adding steps and materials for cutting and wiring individual cells makes the process more expensive.

Increased Potential for Microcracks: When solar panels are cut in half, more edges are created which can lead to weak points in the cells, increasing the chance of microcracks. The sides of the panel might be more prone to tiny cracks that can affect how well it works and how long it lasts.

Reduced Shade Tolerance in Some Configurations: Some configurations have reduced shade tolerance. Solar panels that are cut in half are usually better at handling shade, but some wiring setups may still have lower efficiency when only partially shaded. To get the best results, it’s important to think about how the panels are arranged and the amount of shade they receive.

Higher Vulnerability to Hot Spot Effects: Half-cut panels can still get hot in certain areas, even though they spread heat across more cells and help reduce hot spot effects. If the shading on solar panels is not even or the cells don’t match, some areas may get hotter than others. This can harm the performance and durability of the panels.

Limited Compatibility with Certain Mounting Systems: Half-cut solar panels may not work with some mounting systems or installation setups. These panels may not fit perfectly with some mounting configurations, so you may need to make some adjustments or customize them.

Should I invest in half-cut solar panels?

Half-cut solar panels are a new development in the solar industry that helps photovoltaic modules work more efficiently. Although they cost slightly more (only about 0.6-1.2% more than standard c-Si PV modules), they provide a notable increase in power output, approximately 2-4%. These are great for small spaces with limited room for many PV modules.

Half-cut solar panels are a good choice for places with limited space. They also work better in areas that often have shade. If we use more sub-strings, the system can handle some shading without losing a lot of power like traditional systems do.

There is no need to worry about the durability of smaller solar cells used in half-cut panels. These panels are as durable as regular solar panels because they have a glass covering that protects them. Solar panels are a reliable and valuable investment.

Making half-cut cells is harder, so there aren’t as many of them available. It’s not easy to start making half-cut solar modules by just adding the cells to the current production line.

Although traditional solar panels are still useful in many cases, half-cut cells are more suitable for certain situations. For instance, when there is not enough sunlight on the roof throughout the day. Solar panels are good for places that are far away from cities and for getting the most energy possible from net metering. If you don’t have much space but want to get the most out of your solar panels, choosing half-cut cells is a good idea. If you’re using regular solar panels, that should be okay. But you might need to use solar panel design software to figure out the best way to place them on your roof.

Half-cut cells may become cheaper and more common in the future as manufacturing processes improve. To make a wise investment, it’s best to talk to a solar installation expert who can advise if half-cut cells are suitable for your rooftop solar installation.

How to take care of half-cut solar panels?

It’s important to maintain half-cut solar panels to keep them working well and lasting a long time. Here are some tips to help you maintain your equipment:

Regular Cleaning: To keep the panels clean, make sure to remove any dirt, dust, leaves, or debris that may collect on the surface. To clean the panels, use a soft brush or sponge with mild detergent and water and clean them gently. Don’t use rough materials or strong chemicals that might harm the protective coating.

Check for Damage: Look for cracks, chips, or loose connections by doing regular visual inspections. If you see any problems, get in touch with a professional technician to check and fix the panels quickly.

Shading Management: keep an eye on the area around you for any potential shading problems. Cut back branches that hang over the panels or remove any objects that block the sunlight. Shading can lower the energy output of the panels.

Wiring and Connections: Check the wiring and connections often to make sure they are tight and not corroded. If the connections are loose or damaged, the panels may lose power and their performance may be affected. If you’re not sure or see any problems, ask an expert electrician or solar professional for help.

Monitoring Performance: check the energy production regularly. Solar systems often have monitoring software that lets you keep track of the energy they produce and notice any big decreases in performance. If you see a big drop, it could mean there’s a problem that needs fixing.

Professional Maintenance: Consider scheduling regular maintenance visits with a qualified solar technician to keep your solar system in good condition. They can check everything thoroughly, test the systems, and fix any maintenance or repair issues in a professional manner.

Safety Precautions: Remember to prioritize safety when performing maintenance tasks. Make sure to turn off the system and follow the manufacturer’s safety guidelines before cleaning or inspecting the panels. If you’re not sure or don’t feel confident about doing maintenance tasks, it’s better to get help from a professional.

To keep your half-cut solar panels working well and lasting a long time, follow these maintenance practices for optimal performance and efficiency. Keeping up with regular maintenance will help you get the most out of your solar investment and allow you to enjoy clean and sustainable energy for a long time.

Since 2008, Maysun Solar has specialized in producing high quality photovoltaic modules. We have a wide variety of half-cut solar panels to choose from, and they offer superior performance and stylish designs that will blend in perfectly with any building.

You can have complete confidence in the quality of Maysun Solar’s solar panels. Join us in creating a greener world by harnessing the power of the sun. Contact Maysun Solar now and let’s build a sustainable future together.

New Photovoltaic news you should know about (March 2024)

Table of Contents REC Unveils a 430 W Heterojunction Solar Module Boasting 22.2% Efficiency REC, a Singapore-based PV module manufacturer, introduces its residential solar modules featuring Alpha heterojunction cell technology. Production has commenced at REC’s Industry 4.0 fab in Singapore, with initial shipments

IBC Solar Modules vs. Bifacial Glass-Glass Solar Modules: Which Is More Suitable for Winter or Low-Light Conditions?

Table of Contents Introduction As the demand for renewable energy continues to surge, advancements in solar technology have broadened the spectrum of component choices available to us. Among these, IBC (Interdigitated Back Contact) full black solar modules have garnered special attention due to

Why Are Lightweight Bifacial Solar Panels the Best Choice for Balcony Solar Power Plants?

Table of Contents In the quest for efficient and eco-friendly home energy solutions, solar photovoltaic technology has emerged as a key player due to its sustainability and clean energy benefits. Particularly in the space-constrained urban settings, the effective conversion of every inch of

Questions You Might Ask About Balcony Solar Power Plants in 2024

Table of Contents What is a Balcony Solar Power Plant? Similar to a traditional photovoltaic panel, a Balcony Solar Power Plant is a device designed to generate electricity from solar energy. This green energy generator is specifically tailored for self-consumption, but it comes with

A Step-by-Step DTU Guide for Balcony Solar Power Plants

As renewable energy becomes increasingly integral in our daily lives, Maysun Solar’s Balcony Solar Power Station, with its advanced technology and user-friendly design, represents a transformative approach to home solar solutions. The integration of a Data Transfer Unit (DTU) enhances its smart functionality

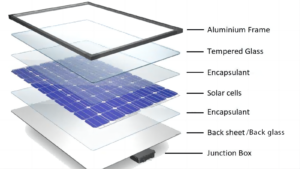

What Are The Main Components of Solar Panels?

What are the main components of solar panel? Solar panels, the cornerstone of solar energy technology, are composed of several integral parts, each contributing to their ability to harness sunlight and convert it into electrical energy. In this article, we will explore the essential