Table of Contents

Why Is Solar Panel Testing and Certification so Important?

Solar panel testing and certifications are important for several critical reasons:

Quality and Safety Assurance: Solar panel testing and certification are essential to ensure that these products meet stringent quality and safety standards. This instills confidence in consumers and businesses regarding the reliability and safety of their investment. Safety is of utmost importance as solar panels generate electricity and face various environmental challenges, thereby reducing the risks of electrical and fire hazards.

Performance Validation and Environmental Impact: Solar panel testing validates performance factors such as efficiency, energy output, and durability, crucial for efficient and dependable solar energy systems. Certifications also ensure adherence to industry, national, and international regulations and standards, facilitating market acceptance and access to incentives. It offers consumers assurance for the longevity of solar panels designed to operate for over 25 years. Additionally, certifications promote industry research, driving technological advancements and efficiency, while also guiding consumers toward eco-friendly choices by assessing environmental sustainability.

In summary, solar panel testing and certification guarantee safety, quality, and performance, fostering trust in clean energy sources, and supporting the growth of the solar energy industry.

Are the Agencies Responsible for Setting Standards for Solar Panel Certification and for Testing and Certification the Same?

The organizations that set industry certification standards for solar panels and the testing and certification agencies are usually separate entities with distinct roles in the certification process.

PV Industry Certification Standard-Setting Agencies: These are non-profit or governmental agencies, like the IEC, ISO, UL, and NREL, responsible for creating performance, safety, and quality standards for solar panels. They establish requirements for products to meet global and domestic markets. Their role is standard development, not testing. In addition to this, CE and MCS are very common certification standards for the PV industry. CE (Conformité Européenne) marking is a self-declaration by manufacturers indicating that their products comply with European Union (EU) standards and regulations. MCS (Microgeneration Certification Scheme) is a UK-based certification program that ensures the quality and performance of microgeneration and renewable energy technologies.

Testing and Certification Agencies: These are independent labs or agencies, such as TÜV SÜD, TÜV NORD, TÜV Rheinland, ECM, and Intertek, authorized to test and confirm solar panels’ compliance with specific standards and regulations. They perform performance, safety, and quality tests.

What Are Some Common Solar Panel Certifications?

Common types of solar panel standards and certifications found in Europe include: IEC, CE, UL, ISO, MCS and UL.

1.IEC: International Electrotechnical Commission

The International Electrotechnical Commission (IEC) is a non-profit organization that establishes global standards for electronic devices, including photovoltaic (PV) panels. It’s important to note that the IEC does not conduct testing or certification of panels themselves; rather, they establish the standards to be followed by other testing facilities.

(1) IEC 61215: Standards for Crystalline Silicon Terrestrial PV Modules

IEC 61215 is a fundamental testing standard for residential solar panels. Compliance with IEC 61215 standards signifies that a solar panel module has successfully undergone various stress tests and demonstrates high-quality, performance, and safety.

IEC 61215 standards are applicable to both monocrystalline and polycrystalline PV modules, which are the most prevalent types of solar panels. For different solar electric technologies, such as thin-film solar products, the IEC has established distinct testing standards (e.g., IEC 61646).

Solar panels meeting IEC 61215 standards undergo comprehensive testing, including but not limited to:

1.Evaluation of electrical characteristics (wet leakage current, insulation resistance)

Mechanical load testing (wind and snow)

2.Climate tests (hot spots, UV exposure, humidity-freeze, damp heat, hail impact, outdoor exposure)

3.Furthermore, IEC 61215 tests aid in determining a panel’s performance metrics under standard test conditions (STC), which include temperature coefficient, open-circuit voltage, and maximum power output.

What Are Standard Test Conditions (STC)?

Solar panel performance assessments take place under controlled laboratory settings referred to as Standard Test Conditions (STC). STC has a standard condition: standard test conditions air temperature 25 degrees, atmospheric mass AM1.5 , 1000W/m2. Since these conditions remain uniform throughout the industry, it enables the comparison of performance metrics, including power rating, module efficiency, optimal voltage, and more, among various solar panels.

(2) IEC 61730: Standard for PV Module Safety

Like any electronic device, solar panels carry the risk of electrical shock if not constructed properly. IEC 61730 addresses the safety aspects of solar panels, encompassing an assessment of module construction and testing requirements to evaluate electrical, mechanical, thermal, and fire safety. PV modules that successfully pass IEC 61730 tests exhibit a low risk of these types of hazards.

(3) IEC 62716: Ammonia Corrosion Testing of Photovoltaic (PV) Modules

For individuals residing near farms or agricultural areas, IEC 62716 is essential for assessing a module’s resistance to ammonia exposure. While most users may not encounter high concentrations of ammonia in relation to their PV modules, those installing solar panel systems in proximity to farms and livestock should be concerned. Ammonia corrosion can accelerate panel degradation, leading to reduced electricity production over the system’s lifespan.

(4) IEC 61701: Salt Mist Corrosion Testing

For those fortunate enough to install solar panels in beachfront locations, it’s advisable to check if the panels have successfully passed IEC 61701 tests. These tests involve subjecting panels to controlled salt sprays. Following the sprays, testers inspect the modules for physical damage, such as corrosion or delamination, and assess their electrical output and overall performance. Panels that meet the requirements of IEC 61701 testing are a suitable choice for beachfront solar panel systems or those near roads where salting levels are high during the winter.

(5) IEC 60068-2-68: Blowing Sand Resistance Testing

Some solar panels undergo IEC 60068-2-68 testing to evaluate their durability in sandy desert environments. Frequent exposure to abrasive sand can lead to physical or mechanical defects over time. Therefore, if you are planning to install solar panels in an area prone to sand or dust storms, it is advisable to choose panels that have successfully passed these tests to enhance the durability of your system.

Maysun Solar subjects the production process to regular inspections by external agencies such as TUV and SGS. Our production lines are automated and this is realised throughout the entire process, including component quality inspection as well as quality inspection during and after production. All glass-glass and single-glass solar panels from Maysun Solar have successfully passed Standards for Crystalline Silicon Terrestrial PV Modules Testing, Standard for PV Module Safety Testing, Salt Mist Corrosion Testing and Ammonia Corrosion Testing, and we have obtained the relevant certifications.

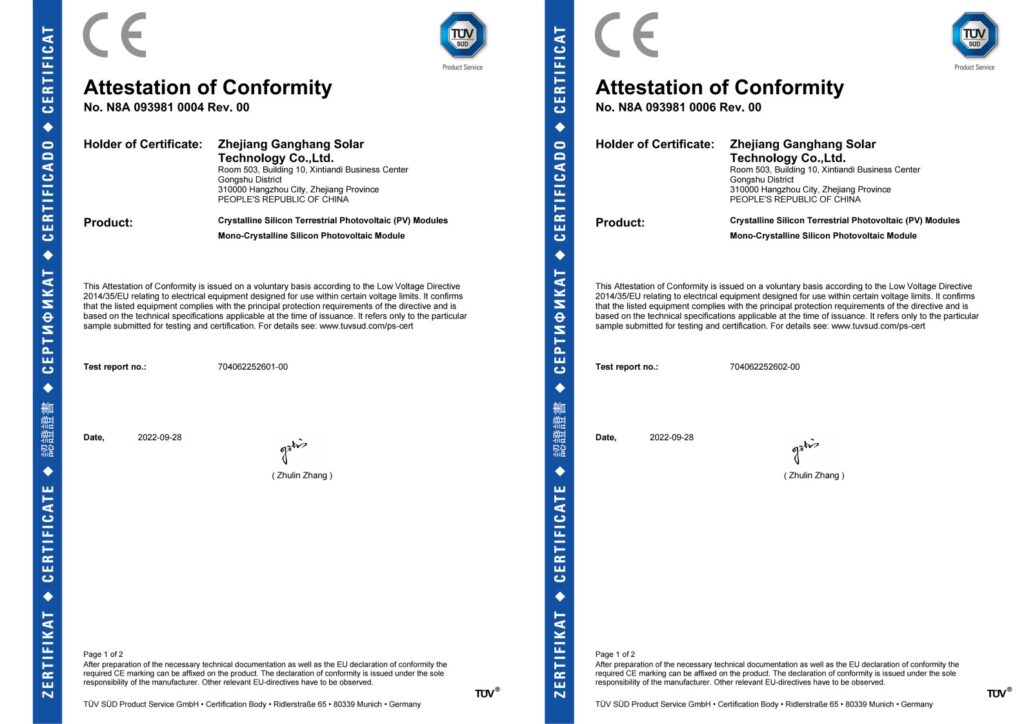

2.CE (Conformité Européenne)

Conformité Européenne (CE) is affixed to products to affirm compliance with regulations set forth by the European Union, serving as an Authentication Certificate. In the present context, the applicable geographic area encompasses the European Economic Area (EEA), which encompasses not only the 28 European Union (EU) member states but also includes Iceland, Liechtenstein, Norway, Switzerland, and Turkey. The CE mark signifies that the product has been manufactured in accordance with the safety, health, and environmental requirements of the EU.

The CE (Conformité Européenne) certification in the solar panel industry is a mandatory certification for the European market, applicable to solar panels and their related components and accessories. This certification ensures that products comply with European regulations and safety standards, allowing them to be legally sold and circulated in the European market. For the distribution of your solar products within the European market, obtaining the CE mark is an absolute necessity. Manufacturers are required to undergo a series of tests and assessments, including electrical performance, mechanical performance, fire resistance, and weather resistance testing, to ensure product performance and safety. Solar panels that have obtained CE certification can carry the CE mark, indicating their compliance and simplifying the process of entering the European market. This certification contributes to enhancing the competitiveness of products and provides assurance of legality and safety for users, thus promoting the widespread adoption of solar panels in the European market. All of Maysun’s solar panels (including different cell sizes such as 166mm, 182mm, 210mm series) are CE compliant. Below are the CE certificates we have obtained:

3.ISO (International Organization for Standardization)

When it comes to ISO (International Organization for Standardization) certification, it is an internationally recognized certification standard frequently employed in the photovoltaic (PV) industry. Manufacturers utilize ISO certification to demonstrate compliance with a range of quality and environmental standards for their solar panels. ISO standards are globally applicable and encompass various domains, including quality management, environmental management, and food safety. This allows manufacturers to select specific ISO standards relevant to photovoltaic products to enhance product quality, sustainability, and environmental friendliness.

Typically, ISO certification is issued by independent third-party testing and certification agencies, ensuring the objectivity and credibility of the certification. In the photovoltaic industry, for instance, ISO 9001 focuses on quality management systems, and ISO 14001 addresses environmental management systems. Obtaining ISO certification assists manufacturers in increasing their products’ competitiveness in the international market, while also conveying a commitment to product quality and environmental sustainability to consumers. Therefore, ISO certification is widely adopted in the photovoltaic industry to ensure that solar panels meet international standards for quality, performance, and environmental compliance.

4.MCS (Microgeneration Certification Scheme)

MCS is the solar panel certification program in the United Kingdom, but it extends beyond solar panels to include other microgeneration systems such as wind turbines, heat pumps, and biomass boilers. The aim of this certification program is to ensure that these renewable energy technologies meet specific quality and performance standards in the UK market. It is a part of the UK government’s support for renewable energy development, with the goal of enhancing the safety and sustainability of these technologies.

MCS certification mandates that manufacturers and installers adhere to particular standards related to performance, sustainability, electrical safety, and compatibility with the UK’s electrical grid. To obtain MCS certification, solar panels and other microgeneration systems must undergo evaluation and scrutiny by independent third-party testing and certification agencies, ensuring the independence and reliability of the certification.

The significance of this certification program lies in the fact that MCS certification is a prerequisite for these technologies to enter the UK market, providing consumers with confidence that the systems they purchase meet high-quality standards. This aids in driving the widespread adoption of renewable energy and promotes the growth of the clean energy industry in the UK.

5.UL: Underwriters Laboratories

UL, or Underwriters Laboratories, is a global safety certification organization, headquartered in the United States. They provide testing and certification services for various products, including electrical appliances, industrial equipment, and plastic materials. UL certifications, such as UL 1703 and UL 61730, are widely accepted internationally, including in Europe, and are used to verify the electrical and safety performance of solar panels.

(1) UL 1703: Safety and Performance Standard

UL 1703 is an industry-standard certification that ensures the safety and performance of solar panels. Panels with UL 1703 certification undergo climatic, aging, and safety tests to meet requirements for mechanical loads, fire resistance, and electrical hazards. It is often found alongside IEC 61730 on solar panel spec sheets, with UL 1703 required for North American markets and IEC 61730 recognized globally.

(2) UL 61730: Comprehensive Safety Qualification

UL 61730 combines UL 1703 and IEC 61730 standards, offering a comprehensive approach to international safety and performance certification for solar panel modules. This certification is becoming more prevalent and cost-effective for manufacturers, streamlining the testing process, reducing the number of panel samples required, and cutting testing time and costs for those planning to sell in both North America and international markets.

What Are the Leading European Testing and Certification Agencies in the PV Industry?

In Europe, the main testing and certification agencies for solar panels are TÜV SÜD, TÜV NORD, TÜV Rheinland, SGS, ECM, and Intertek, and the following is a detailed introduction to TÜV and SGS:

TÜV (Technical Inspection Association)

TÜV (German: Technischer Überwachungsverein, English: Technical Inspection Association), translated as the German Technical Inspection Association, is an unofficial organization in Germany that specializes in the inspection of product safety and environmental safety. Its scope of activities includes inspecting factories, motor vehicles, energy facilities, amusement facilities, equipment, and products. Many of its independent branch organizations are also responsible for conceptual research in the fields of energy and transportation, environmental problem-solving, and standard certification.

The precursor of TÜV was established in 1866, initially focusing on the safety of public places and workplaces, particularly the safety of equipment, steam engines, and boilers. By 1870, there were already 43 regional TÜVs, and names like TÜV SÜD, TÜV NORD, TÜV Rheinland, and TÜV Thüringen originated from different regions.

After years of mergers, there are currently five TÜVs in Germany: TÜV SÜD, TÜV NORD, TÜV Rheinland, TÜV Thüringen, and TÜV Saarland / SGS TÜV. There is also an Austrian TÜV. These organizations share the same trademark but operate independently as competitors. They have established the “TÜV Markenverbund” (TÜV Trademark Association) to uphold the reputation of the trademark. The largest among them is the TÜV SÜD Group, with over 24,000 employees at more than 1000 locations worldwide. The only commercially available certification body to match this is SGS, with more than 80,000 employees.

TÜV ensures the quality, reliability, and performance of PV systems through a range of services, including:

Testing and Certification of Solar Panels: This encompasses stress tests for solar panels, quality assurance measures, and value-added services like energy yield tests and quality-controlled PV modules.

Energy Rating and Yield Measurements for Solar Panels: These assessments determine the energy production of solar panels and consider factors such as temperature, angle, and irradiance that impact module performance.

Testing and Certification of Photovoltaic Module Components: This process verifies whether solar panel components like inverters, junction boxes, and connectors meet safety and quality standards.

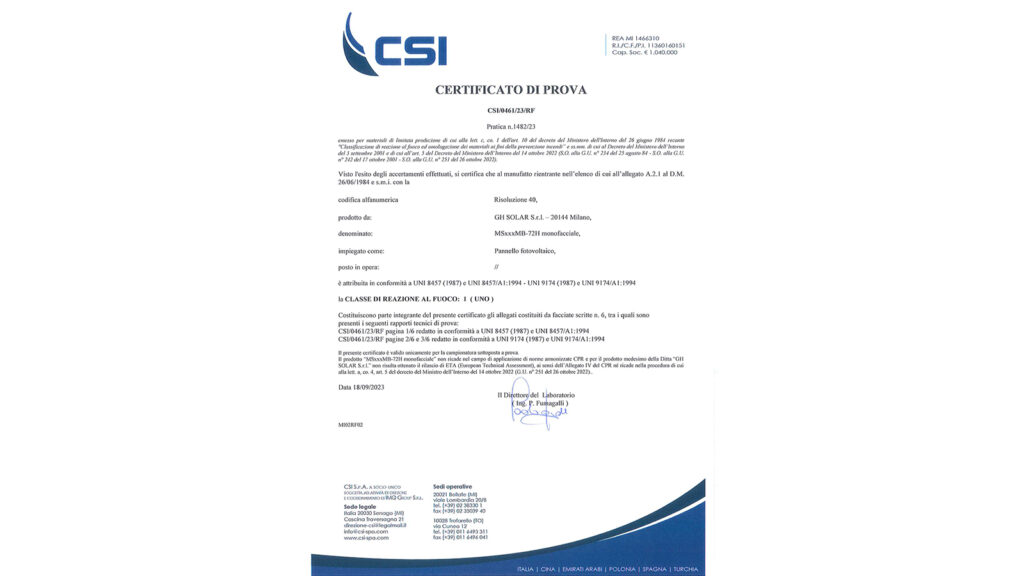

CSI (Certificazione Sicurezza Italiana)

Italy’s CSI (Certificazione Sicurezza Italiana) is a safety certification service that tests and certifies products to ensure that they meet specific safety and quality standards.CSI covers a wide range of sectors, including building materials, electronics, machinery and equipment.

In terms of fire certification, CSI is responsible for testing products for fire resistance to ensure they comply with Italian and European fire safety standards. This may include an assessment of the material’s flammability, flame retardancy, and performance in a fire situation.

Products that receive CSI fire certification demonstrate that they have been rigorously tested and comply with regulatory requirements, which is important when selling products in Italy and other demanding markets. In addition, CSI certification helps to increase consumer and business partner confidence in the safety of products. The picture below shows the CSI certificate obtained by Maysun Solar’s solar panels:

SGS (Société Générale de Surveillance)

SGS is a multinational group specialising in testing, inspection and certification services headquartered in Geneva, Switzerland. With standards for almost all modern products, it has a diverse clientele and, according to its 2021 financial report, employs more than 96,000 people in more than 2,600 specialised laboratories and branches around the world.

SGS offers the following certification services:

Photovoltaic Module Certification: SGS provides certification services for solar photovoltaic modules. This includes testing and verification of the performance, quality, and reliability of photovoltaic modules. The goal of certification is to ensure that these modules comply with international and industry standards to ensure their safety and performance.

Electrical Safety Certification: SGS Group also conducts electrical safety certification to ensure that the electrical components of photovoltaic systems meet relevant safety standards. This includes testing and certification of electrical components such as inverters, electrical connectors, and junction boxes.

System Certification: In addition to module certification, SGS also offers certification services for entire photovoltaic systems. This ensures the performance and reliability of the entire solar power system.

Performance Testing: SGS conducts performance testing of photovoltaic modules to determine their actual energy output and efficiency. These tests typically include electrical performance testing under standard test conditions and performance testing under various climate and environmental conditions.

Environmental Testing: Photovoltaic systems need to operate in various environmental conditions. Therefore, SGS conducts various environmental tests to ensure the reliability of these systems under different climates and weather conditions.

SGS Group’s certification and testing services help the solar industry ensure the quality and performance of its products and systems, promoting the sustainable development of renewable energy. These certifications and tests are typically globally recognized, facilitating product entry into international markets and earning customer trust.

Future Trends in Solar Panel Certification

As we move forward, solar panel certification will increasingly address the accurate prediction of energy output, taking into account varying climate conditions, shading, and geographical locations. Safety innovations will remain at the heart of certification, ensuring that solar systems pose no risks during installation, maintenance, or in emergency situations.

The emergence of “smart” or IoT-integrated solar panels will lead to a closer examination of the reliability and security of these integrated technologies, including data transmission, network security, and performance monitoring. Certification agencies will play a critical role in ensuring the dependability of these advanced systems.

Sustainability will continue to be a paramount concern, focusing on the recyclability and end-of-life disposal of solar panels. Finally, global harmonization of certification standards will reduce market fragmentation, providing consistency and confidence for consumers worldwide.

In essence, the future of solar panel certification will be marked by adaptability to new solar technologies, performance guarantees for consumers, and a steadfast commitment to environmental responsibility and safety. As the solar industry expands, these trends will shape the market and sustain consumer confidence in solar technology.

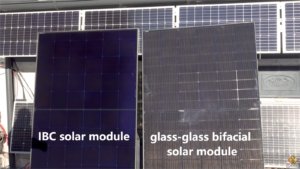

Maysun Solar has been specialising in producing high quality photovoltaic modules since 2008. Choose from our wide variety of full black, black frame, silver, and glass-glass solar panels that utilise half-cut, MBB, IBC, and Shingled technologies. These panels offer superior performance and stylish designs that seamlessly blend in with any building. Maysun Solar successfully established offices, warehouses, and long-term relationships with excellent installers in numerous countries! Please contact us for the latest module quotations or any PV-related inquiries. We are excited to assist you.

New Photovoltaic news you should know about (March 2024)

Table of Contents REC Unveils a 430 W Heterojunction Solar Module Boasting 22.2% Efficiency REC, a Singapore-based PV module manufacturer, introduces its residential solar modules featuring Alpha heterojunction cell technology. Production has commenced at REC’s Industry 4.0 fab in Singapore, with initial shipments

IBC Solar Modules vs. Bifacial Glass-Glass Solar Modules: Which Is More Suitable for Winter or Low-Light Conditions?

Table of Contents Introduction As the demand for renewable energy continues to surge, advancements in solar technology have broadened the spectrum of component choices available to us. Among these, IBC (Interdigitated Back Contact) full black solar modules have garnered special attention due to

Why Are Lightweight Bifacial Solar Panels the Best Choice for Balcony Solar Power Plants?

Table of Contents In the quest for efficient and eco-friendly home energy solutions, solar photovoltaic technology has emerged as a key player due to its sustainability and clean energy benefits. Particularly in the space-constrained urban settings, the effective conversion of every inch of

Questions You Might Ask About Balcony Solar Power Plants in 2024

Table of Contents What is a Balcony Solar Power Plant? Similar to a traditional photovoltaic panel, a Balcony Solar Power Plant is a device designed to generate electricity from solar energy. This green energy generator is specifically tailored for self-consumption, but it comes with

A Step-by-Step DTU Guide for Balcony Solar Power Plants

As renewable energy becomes increasingly integral in our daily lives, Maysun Solar’s Balcony Solar Power Station, with its advanced technology and user-friendly design, represents a transformative approach to home solar solutions. The integration of a Data Transfer Unit (DTU) enhances its smart functionality

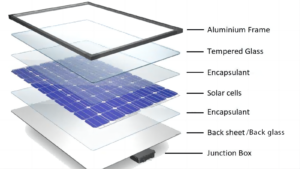

What Are The Main Components of Solar Panels?

What are the main components of solar panel? Solar panels, the cornerstone of solar energy technology, are composed of several integral parts, each contributing to their ability to harness sunlight and convert it into electrical energy. In this article, we will explore the essential

Good write-up. I absolutely love this website.

Stick with it!